Cities all over the country are challenged with maintaining adequate water supplies to meet  the demands of their customer base. Facing new water quality regulations that limited production from existing water wells, Marshall Municipal Utilities (MMU) in southwestern

the demands of their customer base. Facing new water quality regulations that limited production from existing water wells, Marshall Municipal Utilities (MMU) in southwestern

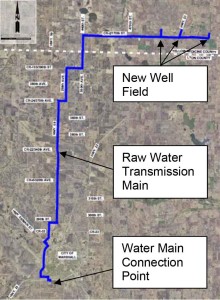

Minnesota developed several new wells to ensure reliable future water supply to Marshall residents. The new wells are located approximately 15 miles north of the City of Marshall. Conveying water from the new wells to the City required approximately 27 miles of raw water transmission pipelines ranging in diameter from 12-inch to 24-inch.

While most of the transmission main on the project was installed by traditional open-cut methods using bell-and-spigot PVC pipe, approximately 8,000 LF of Fusible PVC® pipe was used for crossings that required trenchless installation. Trenchless construction consisted primarily of directionally drilling Fusible PVC® pipe under waterways and road crossings. Because much of the alignment was within Minnesota Department of Transportation (MNDOT) controlled right-of-ways, Fusible PVC® pipe was drilled under many roadways to

avoid disturbance and potentially expensive restoration.

Jeff Larson of MMU had used Fusible PVC® pipe on past projects and liked the approach of maintaining material consistency between the trenchless and open-cut sections of the

project. Based on the findings of a recent study from South Dakota State University (SDSU), MMU and its consultant, DGR Engineering, also decided to use approximately 2,000 feet of 24-inch Fusible PVC® pipe in an area of open-cut construction near high pressure petroleum pipelines. The SDSU Study found that Fusible PVC® pipe outperforms other thermoplastic pipe systems when exposed to petroleum products.

With a lot of interest from regional contractors, favorable bid pricing allowed the project to move forward with Winter Brothers Underground as the prime contractor and MinnComm Underground Utility Construction as the directional drilling contractor. Overall, Fusible PVC® pipe was directionally drilled or sliplined through steel casings on more than 40 separate trenchless crossings along the transmission main alignment.

Pipeline Details and Project Summary

Project Location: Sandnes Raw Water Main, Marshall, MN

Length, Pipe Size: 9,910 LF; 12”,16”, & 20” DR18, 20” & 24” DR21, and 24” DR25

Installation: HDD, Slipline, Open-Cut

Owner: Marshall Municipal Utilities

Engineer: DGR Engineering

Contractors: Winter Brothers Underground, Inc. (prime), MinnComm Underground Utility Construction (HDD sub)

UGSI Contact: Dan Christensen (715) 206-0518, dchristensen@undergroundsolutions.com