Raedlinger Primus Line Job Report:

Client:

Naval Facilities Engineering Command (NAVFAC), Mechanicsburg, PA

Year of Construction:

October 2014

Type of Project:

• Renewing existing 6 inch, 8 inch, and 12 inch cast iron water mains

• Upgrading the water mains from 65 psi operating pressure to 95 psi

Our Services:

• Delivery of the flexible 6 inch, 8 inch, and 12 inch Primus Liner with NSF/ANSI 61 approval

• Delivery of the corresponding end fittings with ANSI flanges (150 lbs) with NSF/ANSI 61 approval

Task:

The Naval facility located in Mechanicsburg, PA was constructed in less than two years during the WWII military expansion. The base consists of over 60 manufacturing and storage warehouses, which required a large amount of water for the manufacturing and fire protection of the base. The water supply was provided by 12 inch, 8 inch, and 6 inch cast iron distribution pipelines throughout the base.

The NAVFAC decided to rehabilitate the 70 year old water mains, because the pipes started to have failures, particularly with the freeze and thaw conditions that occur in the upper Northeast of the United States. In addition, the pipes are affected by corrosion and cracks due to brittleness. Furthermore, NAVFAC intended to potentially increase the operating pressure of the system from 65 psi to 95 psi.

Technical Details:

Host Pipe Material: Cast iron

Transported Medium: Potable water

Transported Medium: Potable water

Host Pipe Diameter: 6 inch, 8 inch, and 12 inch

Operating Pressure: 65 psi and upgrade to 95 psi

Raedlinger Primus Line® System: NSF/ANSI 61 approved system

6 inch Primus Liner with ID = 4.7 inch

8 inch Primus Liner with ID = 6.7 inch

12 inch Primus Liner with ID = 10.6 inch

Total Length: 3 miles

Number of Construction Sections: Multiple sections from 100 ft. to 1,000 ft

Rehabilitation System:

The client opted to renew the corroded water mains with the Primus Line® system, a proven solution for the trenchless rehabilitation of pressure pipelines. The three-layer composite liner consists of a NSF/ANSI 61 certified PE inner coating, a Kevlar® core to accommodate the operating pressure, and an abrasion-resistant PE outer layer to protect the Kevlar® core during the installation process. The semi-structural solution is not bonded to the host pipe, can traverse bends of up to 45 degree, and can be inserted in lengths of 3,000 ft. and

more in one single pull.

Project Description:

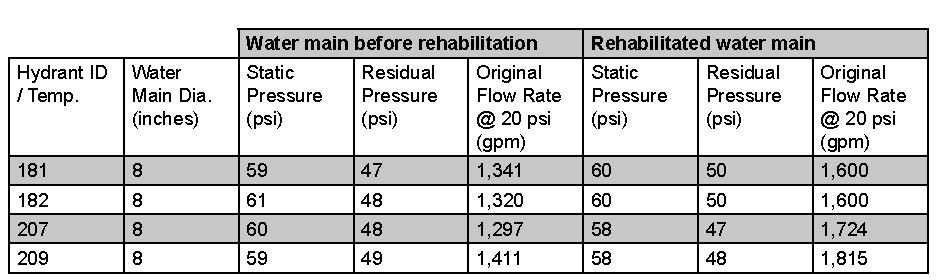

The design-build team was tasked in April 2014 with the execution of this project. The base operations needed to be maintained, the building water and fire lines needed to remain active while renewing and upgrading the existing water infrastructure. A temporary by-pass system made of 6 inch and 8 inch HDPE pipes with 10 hydrants and 20 building connections had to be set-up. The host pipes had to be CCTV inspected to identify tuberculation, sharp edges, and sediment. Metal scrapers and swabs were used to remove tuberculation and sediment. After a subsequent CCTV inspection, the pre-folded Primus Liner was installed with a pulling winch with installation speeds of 20 ft./min. The individual Primus Line sections were expanded by applying compressed air of 7 psi and terminated with low pressure Primus Line end fittings equipped with ANSI flanges (150 lbs). A hydrostatic test with 150 psi was performed and the water mains were disinfected with chlorine. A flow test was performed before and after the installation of the Primus Liner. Despite a smaller diameter, the flow

rates improved by up to 20 % because of the improved C-factor.

Visit Raedlinger Primus Line’s website for more information.