Industry News

Rock Underground, located in the city of Greenfield, MN, is an expert in utility work and exclusively uses Vac-Tron units for locating underground utilities. “All we run is Vac-Tron, every crew we have runs a Vac-Tron model,” says Adam Rock, Founder of Rock Underground.

Rock Underground, located in the city of Greenfield, MN, is an expert in utility work and exclusively uses Vac-Tron units for locating underground utilities. “All we run is Vac-Tron, every crew we have runs a Vac-Tron model,” says Adam Rock, Founder of Rock Underground.

Project Descriptions

Potholing and locating underground utilities safely and efficiently.

Solution

Vac-Tron’s LP 873 SDT vacuum excavator. Vacuum excavation is the best method of identifying the location and accurate depth of a utility. “Being in the utility business we have to pothole utilities all the time; whether it’s a gas line, fiber optic, telephone cable, we use a Vac-Tron vacuum excavator 90% of the time to verify utilities so we don’t hit them,” says Rock.

The LP SDT series is the top selling High CFM Diesel trailer for Vac-Tron. It includes a Yanmar 49 hp Tier 4 final diesel engine with 1,000 CFM vacuum blower for both wet/dry applications.

The LP SDT series is the top selling High CFM Diesel trailer for Vac-Tron. It includes a Yanmar 49 hp Tier 4 final diesel engine with 1,000 CFM vacuum blower for both wet/dry applications.

Rock said “I chose high CFM obviously for the capability of what it can do sucking up the dirt. Everybody can buy the water pressure, everybody can buy the blower, but the technology of the unit itself, the trailer setup, and the power it has, is why we choose Vac-Tron.”

Results

- Accurately and safely verifying underground utilities

- Productivity increase

- Efficiency with time and money

- Being able to clean other equipment

- Many other uses and applications…

Vac-Tron’s LP (Low Profile) series is the premiere line of industrial vacuums and vacuum excavation equipment. Available with gas or diesel engines and high or low CFM. The LP Series starts with 300-gallon debris tanks and goes up to 1,200-gallon debris tanks.

Vac-Tron units come standard with the patented (Big Red) CVS filtration system that is unmatched by competitors, a reverse pressure system, and a heavy-duty I-beam trailer with Dexter torsion axles. The low-profile trailers are hand built at the factory in Florida from the ground up keeping the components of the unit easily accessible while making the unit safe to tow and a much smoother ride. It also provides the best ground clearance in the industry for right of way maneuverability.

For more info or for a FREE Demo visit www.vactron.com or call 1-888-VAC-TRON.

Industry News, trenchless projects

Project profile submitted by Insta-Pipe – Trenchless Pipe Repair using the Pull in Place pressure liner “PRIMUS Line”.

Client: Southwest Suburban Sewer District

Client: Southwest Suburban Sewer District

Engineering and Installation Partner: Insta Pipe – Trenchless Pipe Repair, Olympia, WA

Year of Construction: May 2016

Type of Project: Rehabilitation of an 8 inch sewer force main with 60psi rating and vertical bends in host pipe alignment

Our services:

- Supply and delivery of the flexible low Pressure 8 inch Primus Liner (ANSI/NSF 61 approved)

- Delivery of the 8 inch Primus Line low pressure connectors (150 lbs)

Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP.

Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP.

Rehabilitation System: After an open communication with Primus Line and Insta-Pipe, the Southwest Suburban Sewer District decided to use the Primus Line® system, a flexible relining solution for the trenchless renovation of pressure pipes. The system convinces with its ability to negotiate bends, the minimally invasive construction footprint and the short installation time. In this particular case, the budget was reduced by over 50% compared to the lowest offers with CIPP and was even cheaper than the Engineer’s Estimate.

Project Description: The decision was to install a Primus Line® DN 200 ND with a nominal diameter of 8 inch and a nominal design pressure of 290 psi. Since the technology works with an annular space to achieve long insertion lengths and negotiate bends, the liner provides an actual outer diameter of 7.165 inch and inner diameter of 6.693 inch. According to the calculation of the technical department of Primus Line, the pressure rating of the system through the bends is 217 psi and thus capable of accommodating the maximal operating pressure of 60 psi along the entire pipe route. To complete the system, the low pressure connectors with an operating pressure of 150 psi were used to guarantee a durable and tensile strong connection.

In a first step, the two excavation pits for the installation of the Primus Line® system had to be created. After that the station was pumped down, the force main was dewatered and the pipe was cut for water jet cleaning and CCTV inspection. Due to the heavy incrustations in the host pipe this was performed in a 6 hour window on the first two days, because there was no bypass planned and so the pipe had to be spooled back together in the evening to empty the pump station. After one last cleaning and inspection on the third day, the pre-folded and coiled on a transport reel Kevlar® reinforced composite liner was inserted with speeds up to 15 ft. /min and inflated with 7 psi to bring it back into its round shape. Subsequently the low pressure termination fittings were installed, a pressure test with 60 psi was performed and successfully completed and the pump station was put back into service that evening. During the next morning the pits were closed and the project was successfully accomplished after a total construction time of 4 days and without shutting the pump station down for longer than a daytime window.

Insta-Pipe, Trenchless Pipe Repair

REPAIR SEWERS WITHOUT TRENCHING, WITH SEWER PIPE LINING

With over 25 years of experience, Insta-Pipe Trenchless Pipe Repair can repair sewer and storm lines and repair outside drain pipes with pipe lining services in WA, OR and surrounding areas. Don’t trench when you can take advantage of our pipe lining evaluation and services.

Phone: 360-943-5840 Toll Free: 866-463-9747

855 Trosper Rd SW, 108-204 Olympia, Washington 98512

www.insta-pipe.com

Raedlinger Primus Line, Inc.

112 South Tryon Street, Suite 1130

Charlotte, North Carolina 28284

info@primusline.com www.primusline.com

Industry News, trenchless projects

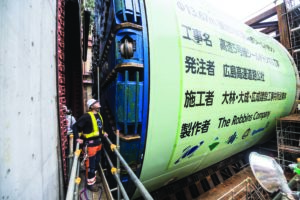

Hiroshima Heavyweight Launches on Expressway Line 5

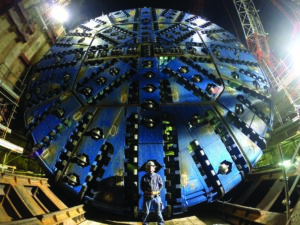

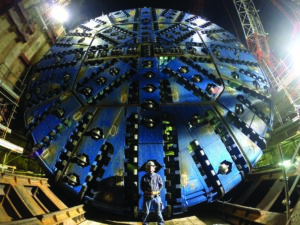

On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The design of the Slurry machine is robust in anticipation of potentially abrasive rock conditions and water pressures up to 13 bars. “The Robbins machine is very tough, for example the weight is very heavy. The cutterhead, both its material and structure, are very tough. It will not break in hard rock,” said Mr. Akai.

In preparation for the conditions, the machine was designed for 20-bar water pressure. The robust cutterhead was fitted with 20-inch and 17-inch diameter pressure compensating cutters, which utilize a patented design to effectively operate under high pressure. The joint venture intends to change the disc cutters an estimated 10 times during the bore as part of the machine’s maintenance.

Throughout the assembly and launch process the joint venture crew worked with Robbins Supervisors who assisted and provided guidance. “Robbins crews have a lot of experience; they help us every day despite the language barriers. I appreciate it,” said Mr. Akai.

The new Expressway Line 5 tunnel will directly connect Hiroshima’s urban area with a major national highway network and is expected to improve access to Hiroshima Airport. Tunnel completion is planned for 2020.

Image 1: Robbins crews assisted the contractor during Onsite First Time Assembly (OFTA) of the massive Slurry TBM in a jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long.

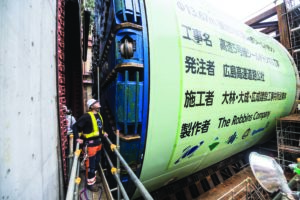

Image 2: The 13.7 m (44.87 ft) diameter Robbins Slurry machine launched on September 18, 2018 in Hiroshima, Japan.

Image 3: Guerin Nolasco of Robbins Field Service looks on during testing of the segment erector inside a mega-sized slurry machine at the Hiroshima Expressway Line 5 project.

Industry News, trenchless products

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, will be highlighting its StructureScan Mini XT and StructureScan Mini LT systems, and the StructureScan Palm XT antenna at The American Society for Nondestructive Testing Annual Conference, being held October 28-30, 2018, at the George R. Brown Convention Center in Houston, Texas. GSSI will be

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, will be highlighting its StructureScan Mini XT and StructureScan Mini LT systems, and the StructureScan Palm XT antenna at The American Society for Nondestructive Testing Annual Conference, being held October 28-30, 2018, at the George R. Brown Convention Center in Houston, Texas. GSSI will be  exhibiting its products at booth #941.

exhibiting its products at booth #941.

StructureScan Mini XT – the newest generation of GSSI’s popular all-in-one concrete inspection GPR system is ideal for locating rebar, conduits, post-tension cables, and voids. The Mini XT can help identify structural elements, including pan decking and concrete cover, and can also provide real time determination of concrete slab thickness. StructureScan Mini XT is the perfect blend of price and performance and is backed by a two-year warranty. It features an intuitive touchscreen interface and six-button control options.

Visitors to the booth can also see a demonstration of the newest accessory for the StructureScan Mini XT. The Palm XT Antenna is a miniaturized GPR antenna that is designed to greatly enhance the capabilities of the StructureScan Mini XT. The handheld Palm XT antenna turns a basic Mini XT into an advanced system by giving users unparalleled access in tightly spaced areas and enabling overhead scanning. Designed to withstand challenging construction sites, the Palm XT is an excellent choice for contractors and engineers alike who need to perform nondestructive testing of concrete structures.

In addition to the Mini XT and the Palm XT accessory, GSSI will be displaying the StructureScan Mini LT. This unit is an integrated all-in-one concrete inspection tool that can help identify structural elements like concrete cover and provides real-time concrete slab thickness measurements. The Mini LT is an all-in-one GPR system that is IP 65-rated to withstand a jobsite’s toughest conditions and features an easy-to-use interface. The StructureScan Mini LT is the perfect entry-level concrete inspection system.

About GSSI

Geophysical Survey Systems, Inc. is the world leader in the development, manufacture, and sale of ground penetrating radar (GPR) equipment, primarily for the concrete inspection, utility mapping and locating, road and bridge deck evaluation, geophysics, and archaeology markets. Our equipment is used all over the world to explore the subsurface of the earth and to inspect infrastructure systems non-destructively. GSSI created the first commercial GPR system nearly 50 years ago and continues to provide the widest range and highest quality GPR equipment available today.

Industry News, trenchless products

VZ Environmental is an innovative leader in secondary drip and spill containment for the oil and gas industry. Carol Van Zandt, owner of VZ Environmental, was challenged by a customer to find a simple method to contain liquid spills in the oil and gas industry. Carol partnered with an equipment supplier to design a drive-over foam bermed containment membrane (VMatz™) to capture and dispose of drips and spills on oil and gas sites. They then utilize a Vac-Tron vacuum excavator to clean up the spill from the containment membrane for proper disposal.

VZ Environmental is an innovative leader in secondary drip and spill containment for the oil and gas industry. Carol Van Zandt, owner of VZ Environmental, was challenged by a customer to find a simple method to contain liquid spills in the oil and gas industry. Carol partnered with an equipment supplier to design a drive-over foam bermed containment membrane (VMatz™) to capture and dispose of drips and spills on oil and gas sites. They then utilize a Vac-Tron vacuum excavator to clean up the spill from the containment membrane for proper disposal.

Today, VZ Environmental provides equipment nationwide, servicing areas in five states and have plans for further domestic and international expansion to continue to help oil and gas operators minimize their impact on the environment.

Today, VZ Environmental provides equipment nationwide, servicing areas in five states and have plans for further domestic and international expansion to continue to help oil and gas operators minimize their impact on the environment.

Project Descriptions

VMatz are spill containments that VZ provides for oil and gas operators to minimize their impact on the environment. “Our customers use the VMatz to catch drips and spills while on location and then we come in to cleanup,” says Carol. VZ wanted to provide their own vacuum service to their customers as part of the cleanup process, so that the customer didn’t have to waste time and money calling out for a vacuum truck company and VZ environmental didn’t have to sit on location and wait for the vacuum truck to arrive before they could cleanup.

Solution

Vac-Tron vacuum trailers for vacuum service and cleanup. “The Vac-Tron trailer helps us clean up our VMAtz by removing the fluid from our containments more efficiently and a lot faster. We are not sitting on location waiting on vacuum trucks to arrive. Prior to having Vac-Tron vacuum trailers in our fleet of equipment, we did not offer any type of vacuum service. Our customers had to order a vacuum truck to come help us remove the fluid when we were cleaning our Vmatz. Our Vac-Tron units come with 500-gallon debris tanks and 1,000 cfm which helps us pick up the rocks and sludge that our customers leave in our containments. This is a perfect size because its small and they can park it off to the side, then call upon it as needed,” says Carol.

Vac-Tron vacuum trailers for vacuum service and cleanup. “The Vac-Tron trailer helps us clean up our VMAtz by removing the fluid from our containments more efficiently and a lot faster. We are not sitting on location waiting on vacuum trucks to arrive. Prior to having Vac-Tron vacuum trailers in our fleet of equipment, we did not offer any type of vacuum service. Our customers had to order a vacuum truck to come help us remove the fluid when we were cleaning our Vmatz. Our Vac-Tron units come with 500-gallon debris tanks and 1,000 cfm which helps us pick up the rocks and sludge that our customers leave in our containments. This is a perfect size because its small and they can park it off to the side, then call upon it as needed,” says Carol.

Results

- Saves customers time and money

- Eliminates down time

- Keeps environment safer

“With a Vac-Tron trailer, we can save our customers money through minimizing the number of trips that they have to call out a vacuum truck. When shopping for vacuum trailers, Vac-Tron is by far the best! Our machines, every time you turn them on, they are rip roaring to go. Our employees don’t have time to go through and try to figure out things, they want to flip it on and use it immediately and they want it to work. Vac-Tron does that for us every time,” says Carol.

Check out the full video interview with VZ Environmental here. For more information on Vac-Tron Equipment and its full fleet of vacuum excavators, please visit them online at www.vactron.com or call 1-352-728-2222.

Rock Underground, located in the city of Greenfield, MN, is an expert in utility work and exclusively uses Vac-Tron units for locating underground utilities. “All we run is Vac-Tron, every crew we have runs a Vac-Tron model,” says Adam Rock, Founder of Rock Underground.

Rock Underground, located in the city of Greenfield, MN, is an expert in utility work and exclusively uses Vac-Tron units for locating underground utilities. “All we run is Vac-Tron, every crew we have runs a Vac-Tron model,” says Adam Rock, Founder of Rock Underground. The LP SDT series is the top selling High CFM Diesel trailer for Vac-Tron. It includes a Yanmar 49 hp Tier 4 final diesel engine with 1,000 CFM vacuum blower for both wet/dry applications.

The LP SDT series is the top selling High CFM Diesel trailer for Vac-Tron. It includes a Yanmar 49 hp Tier 4 final diesel engine with 1,000 CFM vacuum blower for both wet/dry applications.

Client: Southwest Suburban Sewer District

Client: Southwest Suburban Sewer District Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP.

Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP. On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV. Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima. The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.” GSSI

GSSI exhibiting its products at booth #941.

exhibiting its products at booth #941. VZ Environmental is an innovative leader in secondary drip and spill containment for the oil and gas industry. Carol Van Zandt, owner of VZ Environmental, was challenged by a customer to find a simple method to contain liquid spills in the oil and gas industry. Carol partnered with an equipment supplier to design a drive-over foam bermed containment membrane (VMatz™) to capture and dispose of drips and spills on oil and gas sites. They then utilize a Vac-Tron vacuum excavator to clean up the spill from the containment membrane for proper disposal.

VZ Environmental is an innovative leader in secondary drip and spill containment for the oil and gas industry. Carol Van Zandt, owner of VZ Environmental, was challenged by a customer to find a simple method to contain liquid spills in the oil and gas industry. Carol partnered with an equipment supplier to design a drive-over foam bermed containment membrane (VMatz™) to capture and dispose of drips and spills on oil and gas sites. They then utilize a Vac-Tron vacuum excavator to clean up the spill from the containment membrane for proper disposal. Today, VZ Environmental provides equipment nationwide, servicing areas in five states and have plans for further domestic and international expansion to continue to help oil and gas operators minimize their impact on the environment.

Today, VZ Environmental provides equipment nationwide, servicing areas in five states and have plans for further domestic and international expansion to continue to help oil and gas operators minimize their impact on the environment. Vac-Tron vacuum trailers for vacuum service and cleanup. “The Vac-Tron trailer helps us clean up our VMAtz by removing the fluid from our containments more efficiently and a lot faster. We are not sitting on location waiting on vacuum trucks to arrive. Prior to having Vac-Tron vacuum trailers in our fleet of equipment, we did not offer any type of vacuum service. Our customers had to order a vacuum truck to come help us remove the fluid when we were cleaning our Vmatz. Our Vac-Tron units come with 500-gallon debris tanks and 1,000 cfm which helps us pick up the rocks and sludge that our customers leave in our containments. This is a perfect size because its small and they can park it off to the side, then call upon it as needed,” says Carol.

Vac-Tron vacuum trailers for vacuum service and cleanup. “The Vac-Tron trailer helps us clean up our VMAtz by removing the fluid from our containments more efficiently and a lot faster. We are not sitting on location waiting on vacuum trucks to arrive. Prior to having Vac-Tron vacuum trailers in our fleet of equipment, we did not offer any type of vacuum service. Our customers had to order a vacuum truck to come help us remove the fluid when we were cleaning our Vmatz. Our Vac-Tron units come with 500-gallon debris tanks and 1,000 cfm which helps us pick up the rocks and sludge that our customers leave in our containments. This is a perfect size because its small and they can park it off to the side, then call upon it as needed,” says Carol.