trenchless people

NASTT is pleased to announce that Kent State University based in Kent, Ohio, has joined the roster of Student Chapters. This brings the Student Chapter count to 19!

NASTT is pleased to announce that Kent State University based in Kent, Ohio, has joined the roster of Student Chapters. This brings the Student Chapter count to 19!

The Chapter will be lead by the following student officers:

President – Tyler Pocsics

Vice President – Alex Ceh

Secretary – Andrew Mozil

Treasurer – Zachary Burke

The Faculty Advisor for the Chapter is former NASTT Student Member, Lameck Onsarigo. Lameck is a graduate of Bowling Green State University and is one of NASTT’s many student success stories! Read more about Lameck’s student experience here. Lameck has since graduated and has gone on to join the faculty at Kent State and will lead the new Student Chapter. NASTT is extremely proud of Lameck and we’re excited for the future of this new Student Chapter! Welcome to the Family, Kent State!

Industry News, trenchless projects

HDD with Fusible PVC® pipe saves Commission $200,000

Overview

Overview

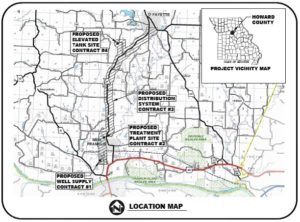

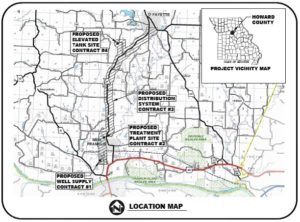

The Howard County Regional Water Commission (HCRWC) was formed in April 2008 with the intent of being a wholesale water provider for the City of New Franklin, the City of Fayette and Howard County CPWSD #1. MECO Engineering has been involved with HCRWC since day one in an effort to assist with design and funding of the required infrastructure. The necessary infrastructure consisted of an alluvial well field, water treatment plant, water tower and distribution mains.

The distribution system design consisted of approximately 68,000 feet of 12-inch waterline, 1,200 feet of 10-inch waterline and 1,200 feet of 6-inch waterline with the majority of the pipe to be installed by conventional open-cut installation. However, there was still a significant amount of the 12-inch waterline that could not be installed by conventional open-cut construction

The distribution system design consisted of approximately 68,000 feet of 12-inch waterline, 1,200 feet of 10-inch waterline and 1,200 feet of 6-inch waterline with the majority of the pipe to be installed by conventional open-cut installation. However, there was still a significant amount of the 12-inch waterline that could not be installed by conventional open-cut construction

based on environmental concerns such as creek crossings or as a result of private property disturbance agreements tied to the issuance of easements. As a result, approximately 8,800 feet of the 12-inch line would need to be installed using horizontal

directional drilling (HDD) installation methodology.

The original plans and specifications included HDPE pipe for the HDD portions of the job. However, during the bid process, Fusible PVC® pipe was allowed as an alternate material for the HDD sections. As a benefit, Fusible PVC® pipe would be able to match the bell-and-spigot PVC pipe being installed in the open cut portions of the job, while the HDPE pipe would need to be upsized in order to provide the same inside diameter. Ultimately the project allowed for two material options in the HDD portion of the job, 12-inch DR 21 Fusible PVC® pipe and 14-inch DR 9 HDPE pipe.

Bids were opened on July 8, 2015 and based on utilizing Fusible PVC® pipe for the HDD sections, C&S Construction out of New London, Missouri was the low bidder. In fact, their bid provided a $200,000 savings due to installing Fusible PVC® pipe instead of the HDPE pipe that was originally specified.

The distribution system portion of the work lasted approximately eight months with all of the Fusible PVC® pipe being installed and tested without any issues.

“We have installed Fusible PVC® pipe on multiple jobs. We really like the way it performs. For this project it allowed us to drill a smaller hole when compared to the HDPE option. Since most of these drills occurred in rock, a smaller hole provides substantial savings of both time and money.” Clinton Ray, Owner Ray’s Construction

Project Story submitted by Underground Solutions, Inc., 858.679.9551

www.undergroundsolutions.com

Industry News

UKSTT are holding their first Masterclass of 2018 on Polyethylene Lining at the Birmingham Motorcycle Museum in Solihull.

Date: 19th April 2018

Venue: Birmingham Motorcycle Museum | Solihull | West Midlands | B92 0EJ

Programme Highlights include:

- PE Pipe: Materials, Properties, Design and Application

- PE Lining: Methods & Techniques, Applications & Design

- Jointing of PE Lining Pipes

- UK & International Standards & Codes of Practice for PE Pipe Lining – Water, Gas & Wastewater

- Pipe Bursting using PE Lining – Upsizing

- Case Studies

- Sliplining

- Close Fit Fold & Form

- Close Fit Diameter Reduction

The UKSTT Masterclasses qualify for a CPD certificate which is an easy way for you to demonstrate your continued efforts to keep your skills and knowledge up to date. To request a CPD certificate please enquire when booking.

To register your attendance please return the Booking Form to admin@ukstt.org.uk

Cost to attend: £150pp + VAT. UKSTT/FWA & PIG members receive a 10% discount. Price includes:

Tea/Coffee & Biscuits on arrival

Mid Morning Tea/Coffee & Biscuits

Two Course Hot & Cold Buffet Lunch

Afternoon Tea/Coffee & Biscuits

Free entry to the Motorcycle Museum

Copies of the full days presentations

Free wifi

CPD Certificate

Industry News

The ASTT Technical Forums are back in 2018!

The ASTT Technical Forums are back in 2018!

After a successful year of forums in 2017, the Australasian Society for Trenchless Technology (ASTT) are pleased to be again offering the following Technical Forums to start 2018:

VIC – Thursday 8 March – 3 to 6.30 pm – Woodward Conference Centre, Carlton

NSW – Thursday 22 March – 3 to 6.30 pm – Sydney Water, Parramatta

For further information on who will be speaking at each forum, please visit the event website.

The forums will be attended by key industry decision makers, contractors and manufacturers, with plenty of opportunities to network over canapés and drinks after the presentations.

Event registration for ASTT members is just AU$45. Registration for non-members is AU$65.

Did you know they also have forums throughout New Zealand in Auckland, Christchurch and Wellington? If you would like further information on these please visit the New Zealand Trenchless Technology Roadshow website.

Interested in presenting or sponsoring any of the ASTT Technical Forums? Please contact Rebecca Burns at rburns@gs-press.com.au.

Industry News, trenchless people, trenchless products

Jacksonville, FL – SIPP Technologies LLC. (SippTech) CEO/CTO Kent Weisenberg announced recently an agreement with SAK Construction, LLC. (SAK) for exclusive installation rights of its SippSteel™ robotic lining technology. Pursuant to the agreement, SAK is the sole national installation contractor for SippTech’s multidimensional, robotically installed, composite pressure pipe lining system.

“SippTech is honored to partner with SAK. Their knowledge, experience, and innovative thinking in the pipeline rehabilitation industry offers the ‘perfect storm’ of opportunity for SippSteel™. SAK has been expertly delivering the most advanced, field proven products to rehabilitate pipes globally for years.” Mr. Weisenberg stated.

SippSteel™ is a novel, three-component composite lining system that entirely overcomes the limitations and inconsistencies present in prior SIPP technologies. This is made possible by utilizing a combination of specific and cooperative machine learning technologies, including computer-vision, LIDAR ultrasound, RF, Wi-Fi, gyroscope, and accelerometer, to precisely navigate and apply the SippSteel™ composite inside of the pipe. The result is the installation of a structurally independent lining system with reduced construction time, minimal consumer disruption, lower costs, and a small environmental footprint.

“This unique, cutting-edge technology truly has the capability to change the entire dynamic of the pressure pipe rehabilitation industry,” stated Charlie Kuhnmuench, V.P. of Business Development for SAK. “We look forward to working together with SippTech to expand this technology throughout the United States. To date, we have not seen a trenchless rehabilitation technology possessing such efficacy and versatility for the pressure pipe industry,” added Jerry Shaw, President of SAK.

Based in O’Fallon, Missouri, and with additional regional offices in Arbutus, Maryland; Sacramento, California; and Nashville, Tennessee, SAK is active across the U.S. The company solves the challenge of maintaining and restoring aging water and sanitary infrastructure for the municipal, energy and industrial markets. With industry-leading experience and a commitment to service excellence, SAK is a trusted partner helping customers worldwide renew, protect and expand their pipeline infrastructure.

SippTech is truly unique in that they are the only SIPP company to conceptualize, design, engineer and manufacture robotic lining systems and develop and manufacture propriety lining polymerics. The result is a synergistic collaboration providing revolutionary, reliable robotic and polymeric systems to the marketplace.

Please visit www.sipptech.com for more information on Spray in Place Pipe technology.

Contact:

Tiffany Laufer

SippTech Technologies, LLC.

tiffanyl@sipptech.com

904.374.5606

NASTT is pleased to announce that Kent State University based in Kent, Ohio, has joined the roster of Student Chapters. This brings the Student Chapter count to 19!

NASTT is pleased to announce that Kent State University based in Kent, Ohio, has joined the roster of Student Chapters. This brings the Student Chapter count to 19!