Uncategorized

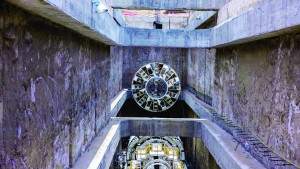

First Rock/EPB TBM in North America represents an Evolution in Design

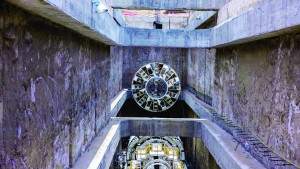

On August 10, 2015, North America’s first Robbins Crossover TBM was launched for the Túnel Emisor Poniente II (TEP II) Project in Mexico City, a complex wastewater scheme for joint venture contractor ALDESA/PROACON/RECSA. Assembled onsite using OFTA (Onsite First Time Assembly), the 8.7 m (28.5 ft) dual-mode type machine is an XRE TBM, and part of the new Robbins Crossover TBM series. The XRE TBM is capable of “crossing over” (X) between two modes, rock (R) and EPB (E), and its fine-tuned design represents a new generation of Crossover machines.

Variable ground conditions necessitated the contractor’s choice of a Robbins Crossover TBM. The 5.9 km (3.7 mi) tunnel consists of sections ranging from fairly competent to weathered volcanic rock, soft sands, and clays. While standard TBMs tend to lose efficiency in these kinds of variable conditions, the Crossover TBM is equipped with special design features to tackle the mixed ground. These field-tested features include a single-direction cutterhead for more efficient excavation in abrasive ground, and multi-speed gearboxes. The specialized gearboxes provide added torque at low RPM in fault zones and soft ground, as well as high RPM for rock boring.

The design of the TEP II machine was based largely on experience from past Robbins projects, in particular the Kargi Kizilirmak Hydroelectric Project in Central Turkey. At Kargi, Robbins supplied a 9.84 m (32.3 ft) diameter Double Shield TBM, based on initial geologic reporting of fractured hard rock. Within 80 m (260 ft) of launch, the geology became substantially more difficult than expected, consisting of blocky rock, sand, clays and water-bearing zones. The machine required multiple bypass tunnels and major modifications before it could resume excavation.

Modifications included a custom-built canopy drill and positioner for enhanced drilling and ground consolidation, gear reducers to adjust torque and RPM to changing ground conditions, and short stroke thrust jacks to double total thrust capabilities. After the modifications, advance rates increased dramatically in the difficult ground and soared to 723 m (2,370 ft) in one month as conditions improved. The modifications proved instrumental to the design of Crossover XRE (Rock/EPB) TBMs, including the TEP II machine.

The contractor at TEP II is confident about the machine’s abilities, which are optimized for hard rock but with many EPB characteristics: “In my opinion, the best part about the design of this TBM is the cutterhead; it is very robust,” said Sebastián Gallego Murillo, TEP II Production Manager for PROACON. He added that the biggest challenge would come near the end of the tunnel drive: “We expect to convert [from hard rock] to EPB mode due to the soils in this area. We will need to change out the cutters and modify the cutterhead.”

The benefits of the project are worth the potential challenges. “This tunnel will reduce flooding in the west and northwest areas of the Valley of Mexico, and increase wastewater capacity. It will benefit three municipalities that are home to 2.1 million people,” said Gallego. Twenty years in the making, the TEP II tunnel will eradicate chronic flooding in the sensitive municipalities of Tlanepantla, Atizapan de Zaragoza and Cuautitlan Izacalli, which have historically been affected with overflows as high as 2 m (6.6 ft) during the rainy season.

Contact Information:

Desiree Willis

Public Relations Manager

Direct: 253.872.4490

29100 Hall Street

Solon, OH 44139 USA

Image 1:North America’s first Robbins Crossover TBM, an 8.7 m (28.5 ft) machine, was launched at Túnel Emisor Poniente II on August 10, 2015 in Mexico City.

Image 2: The machine was assembled using Robbins’ Onsite First Time Assembly (OFTA) method instead of in a shop—a proven way to save both time and money.

Image 3: Robbins Field Service worked proudly alongside the contractor to provide support and training during the complex machine’s assembly and launch.

Want to watch a video of the assembly and launch ceremony? Click here!

Uncategorized

Release Date: 08/31/2015

WASHINGTON — The U.S. Environmental Protection Agency (EPA) is proposing two new hazardous waste rules to strengthen environmental protection while reducing regulatory burden on businesses. One of the proposed rules will protect waterways, including drinking and surface water, by preventing the flushing of hazardous waste pharmaceuticals and simplify the requirements for healthcare workers. The other rule will provide greater flexibility to industry while requiring new safeguards to protect the public from mismanagement of hazardous waste.

“These rules provide businesses with certainty and the flexibility they need to successfully operate in today’s marketplace,” said Mathy Stanislaus, assistant administrator of EPA’s Office of Solid Waste and Emergency Response. “The proposals will improve the safety and health of our communities by providing clear, flexible, and protective hazardous waste management standards.”

The proposed hazardous waste pharmaceuticals rule will make our drinking and surface water safer and healthier by reducing the amount of pharmaceuticals entering our waterways. EPA’s proposal is projected to prevent the flushing of more than 6,400 tons of hazardous waste pharmaceuticals annually by banning healthcare facilities from flushing hazardous waste pharmaceuticals down the sink and toilet.

The proposed rule will reduce the burden on healthcare workers and pharmacists working in healthcare facilities by creating a specific set of regulations for these facilities, including hospitals, clinics, and retail stores with pharmacies and reverse distributors that generate hazardous waste.

EPA’s proposed generator rule will enhance the safety of facilities, employees, and the general public by improving labeling of hazardous waste and emergency planning and preparedness. The proposal will also reduce burden by providing greater flexibility in how facilities and employees manage their hazardous waste and make the regulations easier to understand.

EPA solicited public comment on improving hazardous waste management from states, healthcare facilities, retailers, facilities generating hazardous waste, and other key stakeholders. Both proposals directly address the challenges raised by these stakeholders in implementing and complying with hazardous waste regulations.

The Agency will accept public comments on the proposal for 60 days following publication in the Federal Register.

Read Assistant Administrator Mathy Stanislaus’ blog “Making Hazardous Waste Regulations Work for Today’s Marketplace” here: https://blog.epa.gov/blog/2015/08/making-hazardous-waste-regulations/

For additional information on these proposed rules, including how to submit comments, visit: http://www2.epa.gov/hwgenerators

Uncategorized

BROWNSVILLE, Wisc. – Michels Corporation recently took possession of a new Prime Drilling HDD rig at a key ceremony held in Brownsville, Wisc. The new Prime Drill 80/45 was acquired through trenchless equipment manufacturer TT Technologies, Aurora, Ill. Manufactured by Prime Drilling GmbH, Wenden, Germany the drills have been available in Europe for over 15 years. However, the availability of Prime Drilling HDD rigs in the US market is something that has just occurred over the last few years, facilitated by TT Technologies.

The Prime Drill 80/45 provides 180,000 lbs. of pull force and lightweight profile, weighing only 44,000 lbs. The unit is capable of drilling lengths up to 3200 feet with diameters up to 40 inches. The Prime Drill 80/45 joins Michel’s impressive fleet of over 84 drilling rigs of all sizes, including the largest fleet of 1.2 million pound thrust/pull force capacity rigs in the world.

Pictured in the key ceremony are Benjamin Ploederl, Michels Corporation; Ralf Kiesow, Prime Drilling; and Scott Kneip and Bill Brennan TT Technologies.

Uncategorized

NASTT turns 25 in 2015! What was happening 25 years ago?

On August 23, 1990, East and West Germany announced that they would unite on October 3.

On August 24, 1990, Armenia declared its independence from the Soviet Union.

On August 24, 1990, Darkman was released in theaters starring Liam Neeson.

Check in every Friday in 2015 when NASTT posts more facts about 25 years ago…

Uncategorized

GREENVILLE, S.C.— Fifteen years ago, Tommy Toombs responded to an online job posting  for an underground locating position. The hiring manager was hesitant to hire a novice but Toombs wouldn’t take no for an answer — and his persistence paid off.

for an underground locating position. The hiring manager was hesitant to hire a novice but Toombs wouldn’t take no for an answer — and his persistence paid off.

Now a locator at USIC Inc., Toombs’ determination helped him shine again at the International Utility Locate Rodeo, held at the University of West Georgia, in Carrollton, Georgia, last month. Using a McLaughlin GX locator, Toombs outperformed 16 of his peers to sweep all three water division challenges and win the overall water division competition.

“This was the second year that McLaughlin sponsored me in the Locate Rodeo. I got second place in the water division last year, and I took it all this year,” Toombs said. “I like the challenge of competing in an event where we’re judged on timing and accuracy. It showcases our industry well because every day we’re faced with getting the job done efficiently and accurately so we can move onto the next one.”

Toombs discovered the McLaughlin GX locator about two years ago, when a sales representative conducted a jobsite demonstration.

“My boss told me to ‘just try it,’ and I kinda fell in love,” said Toombs. “The McLaughlin GX does everything that I need it to do.”

The Runner-up

Don Conner, a locating crew leader for Clayton County Water in Georgia, finished second in the Locate Rodeo overall water division competition. An 11-year industry veteran, Conner said he performs water and sewer locates on a daily basis.

“McLaughlin sponsored me last year, and I was really nervous and overthinking every aspect of the locate, and I finished middle of the road,” said Conner. “This year, I was able to keep calm and just focus on the competition. I relied on the GLX locator’s center point to show me that the wand was straight up and down, so I knew I wasn’t throwing off my locates.”

Conner said he hopes to compete in the Locate Rodeo again next year because it’s a “big adrenaline rush.”

For over 90 years, McLaughlin has been actively involved in the drilling tool industry. During that time McLaughlin has developed a reputation for designing and building dependable, low maintenance trenchless construction equipment. McLaughlin takes pride in providing solutions for OEMs and the underground industry.

Please send all reader inquiries to:

McLaughlin Group, Inc.

2006 Perimeter Road

Greenville, SC 29605

Please send all sales inquiries to: