Blog, Industry News, trenchless products

Alternative Lining Technologies (ALT) announces Ace Pipe Cleaning, a subsidiary of Carylon Corporation, as a certified installer of their cured-in-place manhole lining systems throughout the Central United States. Based out of Kansas City, MO, Ace Pipe Cleaning is one of the oldest and largest sewer contractors in the country. While their services and expertise are varied, they focus on sewer cleaning, inspection, and rehabilitation.

Alternative Lining Technologies (ALT) announces Ace Pipe Cleaning, a subsidiary of Carylon Corporation, as a certified installer of their cured-in-place manhole lining systems throughout the Central United States. Based out of Kansas City, MO, Ace Pipe Cleaning is one of the oldest and largest sewer contractors in the country. While their services and expertise are varied, they focus on sewer cleaning, inspection, and rehabilitation.

For 20 years Ace Pipe Cleaning has been the premier contractor for these services in Missouri, Kansas, Oklahoma, Texas, and Arkansas. During that time, they have maintained expertise in a rapidly advancing industry. Aging infrastructure and growing communities have forced the sewer industry to innovate products and technology that seek to maintain collection systems more efficiently. Trenchless technologies, like CIPP, have revolutionized the way communities approach rehab and the associated costs. Similarly, ALT is partnering with contractors, like Ace, to introduce a unique system for rehabilitating manholes and other vertical sewer structures.

Based on the concept of cured-in-place pipe, CIPM liners utilize coated felt and fiberglass combined with epoxy to rehabilitate structures, while stopping I/I and preventing further corrosion. The AltLiner is constructed of panels of felt, which are coated with PVC. These panels are thermally fused to form a sealed liner, custom made for each structure. Fiberglass panels are added for the structural component. The liner is then wet-out onsite and cured under steam and air pressure to conform the liner to the manhole. This creates a strong, corrosion resistant rim-to-invert liner that extends structure life by 50 years or more. Every liner is backed with a 20-year non-prorated warranty.

Alternative Lining Technologies is excited to partner with such a capable and reputable company, like Ace. ALT General Manager, Jim Rouse stated “We believe our system is the best solution for the immense corrosion problem in manholes and pump stations. We are focused partnering with respected installers, like Ace, to prove the value of the system to engineers and

collection systems.” Ace Pipe Cleaning executive, Steve Hontz, echoed Jim’s enthusiasm saying “This is a great solution for structural and hydrogen sulfide protection.”

Ace and ALT are planning demos and presentations in Missouri and Texas this summer to educate the industry about CIPM lining systems. If you’d like more information or to request a

presentation for your organization, contact Bryan Dobson at Ace Pipe Cleaning by calling 800-325-9372.

Blog, Industry News

Trenchless Elevated 2017

Trenchless Elevated 2017

Rocky Mountain Chapter of North American Society for Trenchless Technology (NASTT)

7th Annual Regional Conference

CALL FOR ABSTRACTS

ABSTRACTS MUST BE SUBMITTED ELECTRONICALLY BY JUNE 15, 2017

PAPER TOPICS:

The Rocky Mountain Chapter of NASTT (RMNASTT) is now accepting abstracts for its 2017 regional conference in Denver, CO just north of the Bronco’s Stadium at The Denver PPA Center on November 8, 2017. Prospective authors are invited to submit an abstract and presentation proposal outlining the scope of their paper and the principal points of benefit to the trenchless industry. A variety of trenchless topics will be covered at the conference, and abstracts from the following subject areas are of interest to the selection committee. Case studies are encouraged.

- PIPELINE REHABILITATION FOR WATER, WASTEWATER & STORM WATER SYSTEMS

- ADVANCED PIPELINE CONDITION ASSESSMENT, INSPECTION

- PIPE BURSTING, HORIZONTAL DIRECTIONAL DRILLING (HDD), LATERAL LINING

- NEW INSTALLATIONS – TUNNELING, MICROTUNNELING, HDD, PIPE RAMMING

- TRENCHLESS RESEARCH, EMERGING TECHNOLOGIES, INDUSTRY ISSUES

SUBMITTAL DETAILS:

Abstract submissions are due by June 15, 2017. On your presentation proposal, please provide author/co-author contact information, presenter contact information, title of paper/ presentation, a brief description of the topic, and your abstract of approx. 150 – 250 words in Word format. For accepted abstracts, a technical paper will be required (1,500 words or less), and will include publication in the conference magazine. A 20-25 minute Powerpoint presentation will take place at the conference. If you are interested in participating, please e-mail your completed abstract, presentation proposal, and contact information to Swirvine Nyirenda snyirend@auroragov.org. Final papers and presentations will be due August 15, 2017.

ABOUT RMNASTT:

RMNASTT is a non-profit organization formed in 2009 to serve as a regional chapter of NASTT. The Rocky Mountain Chapter promotes education and implementation of trenchless technology throughout Colorado, Utah, Montana and Wyoming. The Chapter’s goal is to increase education and awareness of tunneling and trenchless technologies for pipeline rehabilitation and new construction applications. The RMNASTT annual conference and short course are valuable educational and networking events for public officials, engineers, utility company personnel, designers, consultants and contractors who are involved or interested in the construction, rehabilitation, and management of underground utilities.

QUESTIONS?

Benny Siljenberg, 303.625.9502| Benny@LithosEng.com or Joe Lane, 303.619.5060 | jlane@lanecg.com

Blog, Industry News, trenchless projects

Rebuilt TBM Will Bore in La Ciotat, France to Improve Access to Water Supply

A Robbins TBM, recently christened “Augustine”, is being commissioned to undertake its eighth bore after being launched by contractor Eiffage Civil Engineering on March 3. The TBM, which was extensively modernized and upgraded during the rebuild for the Galerie des Janots project in La Ciotat, France, has previously completed seven other successful projects across Europe and Hong Kong. This time, it will bore the Janots gallery to improve access to water in the communities east of the Aix-Marseille-Provence metropolis (Cassis, Roquefort-la-Bédoule, La Ciotat and Ceyreste). “It’s a single machine 3.5 meters (11.5 ft) in diameter, 250 metric tons (275 US tons), and 135 meters (443 ft) long, that will work 24 hours a day for almost 10 months during this operation,” says Marc Dhiersat, Project Director of Galerie des Janots for Eiffage.

A Robbins TBM, recently christened “Augustine”, is being commissioned to undertake its eighth bore after being launched by contractor Eiffage Civil Engineering on March 3. The TBM, which was extensively modernized and upgraded during the rebuild for the Galerie des Janots project in La Ciotat, France, has previously completed seven other successful projects across Europe and Hong Kong. This time, it will bore the Janots gallery to improve access to water in the communities east of the Aix-Marseille-Provence metropolis (Cassis, Roquefort-la-Bédoule, La Ciotat and Ceyreste). “It’s a single machine 3.5 meters (11.5 ft) in diameter, 250 metric tons (275 US tons), and 135 meters (443 ft) long, that will work 24 hours a day for almost 10 months during this operation,” says Marc Dhiersat, Project Director of Galerie des Janots for Eiffage.

Currently, the machine is ramping up as back-up decks are being installed. As of April 2017, the machine has bored more than 51 m (167 ft), mainly encountering limestone. “Limestone is a rock easy to dig, but one can be confronted with the phenomenon of karst,” explains Loïc Thévenot, Director of Underground Works for Eiffage. “For this purpose, the tunnel boring machine is equipped with a probe drill. If the karst is small, we will fill it with concrete. If it is large, we will erect a small parallel gallery.”

Currently, the machine is ramping up as back-up decks are being installed. As of April 2017, the machine has bored more than 51 m (167 ft), mainly encountering limestone. “Limestone is a rock easy to dig, but one can be confronted with the phenomenon of karst,” explains Loïc Thévenot, Director of Underground Works for Eiffage. “For this purpose, the tunnel boring machine is equipped with a probe drill. If the karst is small, we will fill it with concrete. If it is large, we will erect a small parallel gallery.”

Galerie des Janots is one of the fourteen operations designed to save water and protect resources, which are being carried out by the Aix-Marseille-Provence metropolis, water agency Rhône Mediterranean Corsica, and the State Government. The future Janots gallery will replace existing pipelines currently located in the railway tunnel that have significant safety and vulnerability deficiencies with estimated water losses of 500,000 cubic meters (132 million gallons) per year. According to Danielle Milon, Mayor of Cassis, “This is an investment of 55 million euros (USD $59 million) with 11 million in aid from the water agency. This project required 10 years of reflection and work to improve water supply. And water is essential for the development of each municipality, and for citizens’ well-being.”

Augustine is boring a tunnel 2,750 m (1.7 mi) long, and will pass under Le Parc National des Calanques, with cover between 15 and 180 meters (50 to 600 ft), in order to replace the pipes that are currently being utilized for the water supply networks. “[The current pipes] have a capacity of transit limited to 330 liters (87 gallons) per second, which is largely insufficient in the summer period. The objective of the operation is to increase to 440 liters (116 gallons) per second,” says Dhiersat. Once the project is complete, networks can easily be maintained in comparison to the old pipes currently running beneath the railway.

Augustine is boring a tunnel 2,750 m (1.7 mi) long, and will pass under Le Parc National des Calanques, with cover between 15 and 180 meters (50 to 600 ft), in order to replace the pipes that are currently being utilized for the water supply networks. “[The current pipes] have a capacity of transit limited to 330 liters (87 gallons) per second, which is largely insufficient in the summer period. The objective of the operation is to increase to 440 liters (116 gallons) per second,” says Dhiersat. Once the project is complete, networks can easily be maintained in comparison to the old pipes currently running beneath the railway.

Image 1: The 3.5 m (11.5 ft) diameter Robbins Main Beam TBM is boring its eighth tunnel in La Ciotat, France.

Image 1: The 3.5 m (11.5 ft) diameter Robbins Main Beam TBM is boring its eighth tunnel in La Ciotat, France.

Image 2: The Robbins TBM is excavating limestone rock with possible karst cavities for the 2.75 km (1.70 mi) Galerie des Janots Project.

Image 3: Contractor Eiffage Civil Engineering is operating the Robbins TBM, which is ramping up production having bored more than 51 m (167 ft) since March.

Image 4: The Galerie des Janots project will upgrade currently overtaxed water supply lines serving several communities east of France’s Aix-Marseille-Provence metropolis.

Blog, Industry News

Early Bird registrations are now open for ASTT’s No-Dig Down Under 2017. Click here to register. Purchase your full conference registration now and receive AU$200 off till 14 July 2017.

Early Bird registrations are now open for ASTT’s No-Dig Down Under 2017. Click here to register. Purchase your full conference registration now and receive AU$200 off till 14 July 2017.

Nominations are open for the ASTT Awards, winners will be announced at the Official Gala Dinner sponsored by Ditch Witch Australia on Thursday 14 September 2017.

The ASTT Awards recognise excellence, innovation and outstanding achievement in Australia and New Zealand’s Trenchless Technology industry. Nominating your project or colleague will give you and your company international recognition by highlighting your achievement to key-stakeholders in the trenchless industry.

There are five categories available to ASTT members to nominate for. Submit a nomination here before they close on Thursday 1 June 2017.

Project of the year – Rehabilitation

Recognising innovation, advancements in technology, environmental benefits and occupational health and safety benefits in rehabilitation projects utilising Trenchless Technology.

Project of the year – New Installation

Recognising innovation, advancements in technology, environmental benefits and occupational health and safety benefits in new installation projects utilising Trenchless Technology.

New Technology – Machine, tool, material, system or technique

New Technology should demonstrate a practical development of trenchless systems or equipment that results in benefits such as improved economy, accuracy, speed of drive or replacement, ability to overcome difficult installations, or similar.

Person of the Year

The award recognises a contribution over and above the call of duty to grow, develop and promote the use of Trenchless Technology across Australasia and indeed around the world.

Young Person of the Year

Someone who is engaged with the industry and the promotion of Trenchless Technology, has significantly contributed to the industry over the past year, and is aged 40 or under on 1 September 2017.

For more information visit the www.nodigdownunder.com

Email or call conferences@gs-press.com.au or +61 3 9248 5100 for any additional questions.

Blog, Industry News

Complements rescue dogs to quickly locate survivors

Written by: Tom Timperman, GSSI

Disaster scenes are chaotic and noisy, with rescue teams climbing over collapsed structures, feverishly working to find survivors. Technology can play an important role in the effort, whether the structural collapse is due to earthquake, human-caused disaster, flood or tsunami, mudslide, avalanche, or even urban terrorism. Several options are currently available, but the most effective option is the combination of highly trained search-and-rescue dogs together with ultra-wide band (UWB) radar. Pairing the dog’s dynamic nose with the UWB radar’s ability to see through building materials in determining the approximate distance to the survivor is a huge benefit for urban search-and-rescue (USAR) teams. Already used successfully all over the world, UWB radar would be a great addition to the tools available to rescuers in the United States and Canada, providing current FCC radio emissions regulations can be amended.

Methods used to locate survivors trapped under collapsed debris

Four technologies are typically used by USAR teams to locate survivors of structural collapses at disaster scenes: Rescue dogs, acoustic vibration monitoring devices, borehole cameras, and ultra-wide band (UWB) radar.

Each method has its advantages and disadvantages. Here’s a run-down of the most commonly applied methodologies.

Rescue dogs are indeed amazing. Quick and effective, trained dogs are incredibly dynamic, can cover large areas, and work remotely from their handler. However, dogs cannot determine the distance to a buried survivor, and can be affected by scent drift during windy conditions. Just like humans, they are also prone to fatigue and stress, and require downtime to recuperate. An eye-opening report on the limitations of search-and-rescue dogs came out of the recent large earthquake in Ecuador. The emotional story concerned a beloved and acclaimed dog that found a handful of survivors, only to succumb to heat exhaustion due to over-use.

Acoustic vibration monitoring devices can be placed on top of the rubble pile to listen for sounds from a survivor – tapping, yelling, kicking, or noise of any kind. They require a high level of user expertise, and require almost complete silence. Such silence is very difficult to achieve at these frantic scenes, where military, police, and fire department personnel are present, along with relatives and other rescue groups. The greatest disadvantage to acoustic devices is that they require active participation by a survivor. If the survivor is incapacitated or unconscious, they will unfortunately not be capable of such participation.

A borehole camera is a lightweight, three-in-one device that contains a small camera, flashlight, and microphone. These sophisticated “selfie sticks” provide visual confirmation of the presence of a survivor or victim. They enable two-way communication between rescuers and survivors, but have a limited depth of penetration (3-4 meters) compared to other options. Their primary drawback is that they require direct line-of-sight to the survivor through an opening of some kind in the rubble pile, which is not always available.

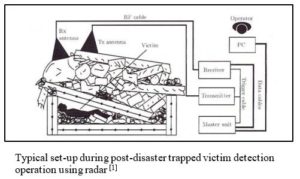

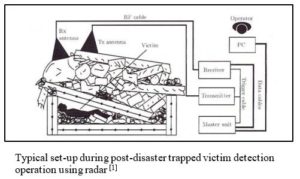

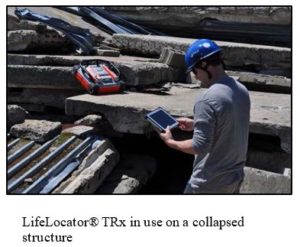

Ultra-wide band (UWB) radar offers the most effective and efficient compliment to search dogs by providing very fine and immediate motion detection. The radar sends out 800,000 pulses per second while measuring the two-way transit time between the unit and the survivor. UWB radar is also extremely safe; the radar energy emitted is equal to one-hundredth of the power emitted by a cell phone.

Application of such radar driven technology is not new, having been widely used for automotive collision-detection systems, wireless communications, indoor positioning, and sensor networks. It has recently been adapted to USAR scenarios because it provides a wider band of radar detection, yet is less susceptible to interference than narrow band radar, which provides poor down-range resolution and inability to accurately determine the distance to the victim [1].

Application of such radar driven technology is not new, having been widely used for automotive collision-detection systems, wireless communications, indoor positioning, and sensor networks. It has recently been adapted to USAR scenarios because it provides a wider band of radar detection, yet is less susceptible to interference than narrow band radar, which provides poor down-range resolution and inability to accurately determine the distance to the victim [1].

As mentioned previously, UWB radar offers the most effective complement when combined with the efforts of the rescue dog. In concert with the dog, rescuers can work quickly and effectively across a predetermined grid on top of the rubble pile. The rescue dog may indicate the presence of a survivor, but cannot tell if the survivor is one, eight, or twelve meters away. By applying UWB radar technology, rescuers can now quickly “localize” the approximate distance to the survivor.

Radar is not diverted by scent, does not get fatigued, and does not require silence or line of site. It is also a good method of determining where not to dig, which is important on a rubble pile.

Radar is not diverted by scent, does not get fatigued, and does not require silence or line of site. It is also a good method of determining where not to dig, which is important on a rubble pile.

Also, it detects user respiratory and cardiac motion, so it cannot be used to detect the deceased. UWB radar cannot see through metal, and is susceptible to noise interference from cell towers or radio communication systems.

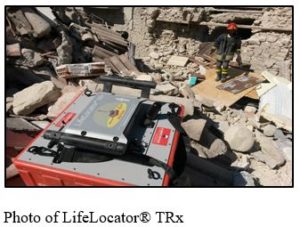

The LifeLocator® TRx

Headquartered in Nashua, NH, GSSI began developing the first UWB radar technology for search-and rescue use in 2002, in response to post-911 Homeland Security market needs. USAR agencies had been seeking technologies that could be adapted to search-and-rescue applications, and they determined UWB radar technology to be an excellent option. The first generation of the equipment was dubbed LifeLocator® and released in 2005.

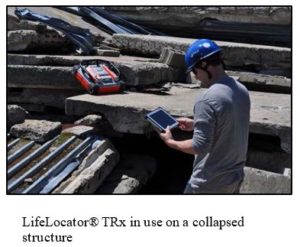

Over the next decade, design improvements were made based on operator feedback and advances in radar technology. In 2015, GSSI released the LifeLocator® TRx, which incorporates a variety of improvements specifically designed to meet the challenging field conditions found in structural collapse search operations. The LifeLocator® TRx detects survivor respirations (as few as 3 per minute; as many as 30 per minute) to a maximum distance of 10 meters (33 feet), and survivor motion to a maximum distance of 12 meters (40 feet).

The TRx can be operated by a single person, and is simple-to-use in detecting survivor motion in as little as 10 seconds. It features a ruggedized design with a Wi-Fi antenna mounted inside the carry handles, making it less susceptible to breakage. The addition of a second battery gives the unit a hot swappable battery configuration, which eliminates downtime while changing batteries on the fly.

More importantly, the TRx now includes greatly enhanced noise filtration and noise immunity capability. The laptop user interface features a noise floor indicator to show the operator the strength of nearby noise interference. This is absolutely critical, since the greater the interference, the greater the possibility of the radar producing a ‘false positive’ survivor location.

Previous generations of the LifeLocator® employed a single radar receiver, while the TRx incorporates twin receivers. Twin receivers improve detection in many situations. For example, if the operator places the system over an area that is partially metal and partially another building material, the TRx will still be able to detect the presence of a survivor under the area that is not under metal. Placing the equipment at different angles gives rescuers different ways to work a pile more intelligently and effectively.

LifeLocator® TRx saves lives

LifeLocator® TRx saves lives

The LifeLocator® TRx has been successfully deployed by fire departments and rescue organizations across the globe in response to major catastrophes. A global French USAR team recorded a save following the 2010 Haiti earthquake, while Chinese rescue teams experienced the same success in Sichuan Province in 2008.

Unfortunately, the cutting edge technology cannot currently be used in the United States and Canada due to existing Federal Communications Commission equipment standards.

To ensure that local search-and-rescue teams have access to the most advanced and reliable technology on the market, GSSI encourages the FCC to consider waiving these standards for manufacturers of such life-saving devices. Such consideration will allow the dedicated USAR community to provide the most reliable support during the most catastrophic circumstances, enabling them to quickly and reliably locate survivors.

[1] Trapped-Victim Detection in Post-Disaster Scenarios using Ultra-Wideband Radar, by AN Nezirović, 2010, repository.tudelft.nl.

Blog, Industry News, trenchless products

Hutchinson, Kansas – StraightLine HDD, Inc. announced the implementation of an upgrade to its popular Performix Mud Mix System. At the heart of the Performix System is the centrifugal pump, which generates the best laminar flow in the industry.

Hutchinson, Kansas – StraightLine HDD, Inc. announced the implementation of an upgrade to its popular Performix Mud Mix System. At the heart of the Performix System is the centrifugal pump, which generates the best laminar flow in the industry.

The performance pump now features an upgraded silicon-carbide shaft seal. Compared to traditional ceramic seals, the new seal represents a considerable advancement in resiliency when subjected to the highly abrasive elements present in mud mixing. In field testing, silicon carbide seals improve service life by a factor of three over ceramic seals.

The Performix pump retains its lubricated housing feature, which protects the pump seal from mechanical damage if the pump ever runs dry.

The new seal is a direct, no-modification required, replacement to the existing ceramic seal.

Alternative Lining Technologies (ALT) announces Ace Pipe Cleaning, a subsidiary of Carylon Corporation, as a certified installer of their cured-in-place manhole lining systems throughout the Central United States. Based out of Kansas City, MO, Ace Pipe Cleaning is one of the oldest and largest sewer contractors in the country. While their services and expertise are varied, they focus on sewer cleaning, inspection, and rehabilitation.

Alternative Lining Technologies (ALT) announces Ace Pipe Cleaning, a subsidiary of Carylon Corporation, as a certified installer of their cured-in-place manhole lining systems throughout the Central United States. Based out of Kansas City, MO, Ace Pipe Cleaning is one of the oldest and largest sewer contractors in the country. While their services and expertise are varied, they focus on sewer cleaning, inspection, and rehabilitation.