Industry News, trenchless products

Challenging Ground Conditions are No Match for Talented Team and their TBM

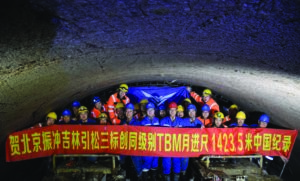

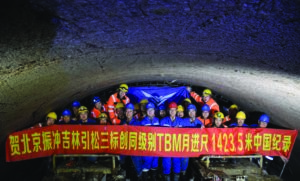

In Jilin, one of the three provinces of Northeast China, a 7.9 m (26 ft) diameter Robbins Hard Rock Main Beam TBM has achieved a national record for 7 to 8 meter (23 to 26 ft) machines: 1,423.5 m (4,670 ft) in one month. The record tops a previously-set achievement on the same project from earlier in 2017, when the TBM advanced at a rate of 1,336.8 m (4,386 ft) in one month.

Hard Rock Main Beam TBM has achieved a national record for 7 to 8 meter (23 to 26 ft) machines: 1,423.5 m (4,670 ft) in one month. The record tops a previously-set achievement on the same project from earlier in 2017, when the TBM advanced at a rate of 1,336.8 m (4,386 ft) in one month.

The world record for the size class is held by another Robbins machine, set more than 20 years ago at the Tunnel and Reservoir Plan (TARP) in Chicago, Illinois, USA, for 1,482 m (4,862 ft) in one month. However, given the differences in rock conditions this Jilin project record is very significant. At TARP the rock was relatively homogeneous dolomitic limestone averaging 145 MPa/21,100 psi with occasional rock bolts; at Jilin the rock types were rated from 35 to 206 MPa UCS (5,100 to 30,000 psi), and identified as tuff, granite, sandstone, and andesite with multiple fault zones—conditions requiring nearly continuous ground support.

Despite the difficult conditions, the Jilin machine has achieved an average monthly advance rate of 708.3 m since the start of boring in March 2015—more than three times the average monthly rate of a Drill & Blast operation on another section of the project. “It is now very evident that well-equipped, open-type Main Beam TBMs with specialized features for difficult ground can traverse faults and large water inflows much faster than conventional tunneling methods. This fact, coupled with the high performance capabilities as demonstrated at Jilin, lowers the cost and time to complete long tunnels in difficult ground,” said Robbins President Lok Home.

The Jilin Lot 3 tunnel, which is being bored as part of a water conservation project, will be 24.3 km (15 mi) long when complete. Under contractor Beijing Vibroflotation Engineering Co. Ltd. (BVEC), the machine has excavated 14 km (8.7 mi) of the tunnel as of January 2018.

The Jilin Lot 3 tunnel, which is being bored as part of a water conservation project, will be 24.3 km (15 mi) long when complete. Under contractor Beijing Vibroflotation Engineering Co. Ltd. (BVEC), the machine has excavated 14 km (8.7 mi) of the tunnel as of January 2018.

Throughout its bore, the Main Beam is expected to traverse a total of 24 fault zones. The TBM was designed accordingly, and is equipped with four rock drills, McNally pockets in the roof shield for the ability to install McNally slats, a ring beam erector, and a shotcrete system. The McNally slats were used in difficult ground encountered in the tunnel.

The McNally Roof Support System was designed and patented by C&M McNally and licensed for exclusive use on Robbins TBMs in certain markets. By replacing the roof shield fingers on a Main Beam TBM, the McNally system prevents movement of loose rock in the critical area immediately behind the cutterhead support. The system has been tested and proven on projects worldwide—including the world’s second deepest civil works tunnel, the 2,000 m (1.2 mi) deep Olmos Trans-Andean Tunnel in Peru—to increase advance rates while still maintaining worker safety on Main Beam machines in difficult rock conditions.

The Jilin TBM’s first fault zone was encountered after just 87 m (285 ft) of boring, requiring cooperation between the owner, Jilin Province Water Investment Group Co., Ltd., contractor BVEC, and Robbins field service. Water inflows and collapsing ground in a section measuring 1,196 m (3,926 ft) long were resolved with a combination of McNally slats, grouting, and consolidation of the ground ahead of the machine. Ground support overall consists of wire mesh and shotcrete. Tunnel Reflection Tomography (TRT)—a method of ground prediction using seismic waves—is also being used to detect changing conditions ahead of the TBM.

Despite the initial challenges, the TBM is now achieving between 40 and 60 m (130 to 197 ft) advance per day. “My colleagues and I all feel that the Robbins TBM is very easy to operate. All components of the system work well during operation, which has ensured our good progress,” said by Tao Yong, BVEC Jilin Lot 3 TBM Site Manager.

The Jilin Lot 3 tunnel is part of the Jilin Yinsong Water Supply Project, which will convey water to the central cities of Jilin Province. The large-scale, trans-regional water diversion project is the longest water supply line, measuring 263.5 km (163.7 mi), with the largest number of recipients benefiting from it in the history of Jilin Province. The construction project will divert the water from Fengman Reservoir at the upper reaches of Di’er Songhua River to central regions of Jilin Province experiencing chronic water shortages. These regions include the cities of Changchun and Siping, eight surrounding counties, and 26 villages and towns under their jurisdiction. Tunneling is expected to be complete in late 2018.

Image 1: The 7.9 m (26 ft) Robbins Main Beam TBM achieved a national record for its size class, excavating 1,423.5 m (4,670 ft) in one month.

Image 2: The crew celebrates the national-record-setting Robbins TBM for China’s Jilin Lot 3 tunnel. The machine excavated in far more difficult ground at a higher rock strength than the current world record holder—also a Robbins TBM.

Image 3: The Robbins TBM was designed with pockets in the roof shield, allowing it to install the McNally Roof Support System while boring.

Industry News, trenchless people

Jacksonville, FL – SippTech LLC CEO/CTO Kent Weisenberg announced recently that the company has finalized a contract with Louisiana Tech’s Trenchless Technology Center for their continued partnership and product analysis of the advancement of Spray in Place Pipe Technology, (SIPP). The awarded contract specifically involves testing of SippTech’s robotic systems and installation of its cutting-edge, filament reinforced composite lining, SippSteel™.

Jacksonville, FL – SippTech LLC CEO/CTO Kent Weisenberg announced recently that the company has finalized a contract with Louisiana Tech’s Trenchless Technology Center for their continued partnership and product analysis of the advancement of Spray in Place Pipe Technology, (SIPP). The awarded contract specifically involves testing of SippTech’s robotic systems and installation of its cutting-edge, filament reinforced composite lining, SippSteel™.

“The Trenchless Technology Center (TTC) is excited to support SippTech through testing, research and developmental support of their innovative Spray-in-Place Pipe (SIPP) technology. This new SIPP technology has high potential to drive the pressure pipe rehabilitation industry forward in the very near future” stated Dr. John Matthews, Director of the TTC and Principal Investigator on the SippSteel™ project. Mr. Matthews further stated, “It is also a monumental moment for the TTC as this is the largest contract awarded to us from a private company since our conception.” Dr. Matthews will be assisted on this four-phased project by co- Principal Investigator’s Dr. Shaurav Alam and Dr. Amin Azimi. Industry professionals, undergraduate and graduate students will also be collaborating during each phase of testing.

“The Trenchless Technology Center (TTC) is excited to support SippTech through testing, research and developmental support of their innovative Spray-in-Place Pipe (SIPP) technology. This new SIPP technology has high potential to drive the pressure pipe rehabilitation industry forward in the very near future” stated Dr. John Matthews, Director of the TTC and Principal Investigator on the SippSteel™ project. Mr. Matthews further stated, “It is also a monumental moment for the TTC as this is the largest contract awarded to us from a private company since our conception.” Dr. Matthews will be assisted on this four-phased project by co- Principal Investigator’s Dr. Shaurav Alam and Dr. Amin Azimi. Industry professionals, undergraduate and graduate students will also be collaborating during each phase of testing.

SippSteel™ is comprised of a composite lining of two dissimilar lining material layers and a carbon fiber filament reinforcement, which are applied robotically in a single pass through the pipe system. The robotic apparatus is self-propelled, and all its mechanical functionalities are controlled autonomously by internal sensors and computer vision. Employing both individually specific and a synergetic combination of computer vision, LIDAR, ultrasound, RF, Wi-Fi, gyroscope, accelerometer and machine learning technologies, the robot can precisely navigate and apply the SippSteel™ composite inside of the pipe. The device can be operated via umbilical or autonomously providing lining lengths of more than a mile from one access point in the pipe.

“The SippSteel™ technology addresses a multitude of customer needs as well as resolving systemic problems in the trenchless technology sector. Today’s pipeline rehabilitation industry has long been searching for an innovative, and more importantly, versatile technology to fulfill all the structurally independent liner requirements” Mr. Weisenberg stated.

Innovative components that ensure that the SIPP system can deliver:

- The ability to provide structurally independent rehabilitation; therefore, significantly optimizing the cost effectiveness and efficacy of the rehabilitation method as well as increasing the design life of the pipeline.

- The ability to rehabilitate long lengths of pipe; therefore, substantially reducing installation time as well as costly and environmentally invasive excavations.

- The ability to negotiate through pipe bends and valves; therefore, substantially reducing excavations that increase costs and disrupt the public.

- The ability to provide a thinner liner system without a resulting annulus between the liner and the host pipe; thereby increasing the comparative cross-sectional diameter and subsequent flow capacity while impeding all potential for infiltration behind the liner which can result in hydraulic failure.

The Trenchless Technology Center (TTC) was initiated as the Trenchless Excavation Center in 1989 and formally established as the Trenchless Technology Center in November 1991. It was created to promote research, development and technology transfer in the trenchless technology industry.

“After several years of painstaking R&D we are tremendously enthusiastic to have entered the final analysis phase with such a highly credible institution as the TTC for the final verification of our compiled scientific testing and empirical data.” stated, Mr. Weisenberg. “We are proud to be revealing SippSteel™ and its capabilities which will revolutionize the industry for the rehabilitation of pressure pipelines in an extensive range of diameters.” Mr. Weisenberg noted.

Please visit www.sipptech.com for more information on Spray in Place Pipe technology.

Contact:

Tiffany Laufer

SippTech Technologies, LLC.

tiffanyl@sipptech.com

904.374.5606

Industry News, trenchless people

You are invited to participate in the 8th Conference of Trenchless Technologies NO-DIG POLAND, which is going to take place on 18-19 April 2018 in Kielce.

The conference began in 2005 and takes place every second year, and each of the previous editions were attended by a number of domestic and international participants (also from outside of Europe), including representatives from the scientific community, water supply and sewerage companies, design and construction companies, manufacturers of materials and equipment used in trenchless technologies.

The topics of the upcoming conference include issues closely related to the use of trenchless technologies in design, construction and renewal of underground infrastructure in the water, sewage, gas, road and rail industries, as well as in trenchless infrastructure tunnels.

The conference is an excellent opportunity to share knowledge and experience between public administration staff, scientists and professionals working in the water and wastewater sector.

For more information visit the conference website.

Industry News, trenchless people, trenchless products

Expanded access and support for HDD rock tooling

PELLA, Iowa, February 15, 2018 – Two of the horizontal directional drilling (HDD) industry’s leading equipment and tooling manufacturers, Vermeer Corporation and Mincon Group PLC, have formed a distribution alliance to expand contractors’ access to quality rock tooling worldwide. As part of the agreement, Vermeer dealers are now the exclusive channel for Mincon HDD air hammer systems, HDD pull reaming hammers and HDD support equipment, including HDD support stations and oilers.

PELLA, Iowa, February 15, 2018 – Two of the horizontal directional drilling (HDD) industry’s leading equipment and tooling manufacturers, Vermeer Corporation and Mincon Group PLC, have formed a distribution alliance to expand contractors’ access to quality rock tooling worldwide. As part of the agreement, Vermeer dealers are now the exclusive channel for Mincon HDD air hammer systems, HDD pull reaming hammers and HDD support equipment, including HDD support stations and oilers.

“Mincon has pioneered HDD rock drilling solutions and when paired with Vermeer drills are productive in hard rock environments,” said Jason Zylstra, product manager, Lifecycle at Vermeer. “With the responsive support provided by Vermeer dealers and quality Mincon tooling, contractors have everything they need to take on challenging rock bores.”

Mincon hard rock hammer systems utilize high-frequency cycle technology that aids in the faster removal of drill cuttings from the bit face while providing the smallest possible chips. This design also improves steering capabilities and causes less vibration in the drill string.

For more information about Vermeer HDD equipment and Mincon HDD tooling, please consult your local Vermeer dealer.

ABOUT VERMEER

Vermeer Corporation delivers a real impact in a progressing world through the manufacture of high-quality tree care, environmental, underground construction, surface mining, and agricultural equipment. With a reputation for durability and reliability, that equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer Corporation, products, the dealer network and financing options, visit Vermeer.com.

ABOUT MINCON

Mincon Group PLC was founded in 1977 in Shannon, Ireland. Mincon manufactures and distributes a range of precision engineered hard rock drilling tools for a variety of industries including mining, exploration, waterwell, geothermal, construction, horizontal directional drilling, oil-gas and energy. Mincon Group PLC has a worldwide presence with offices in Ireland, UK, Sweden, Finland, USA, Canada, Australia, South Africa, Namibia, Tanzania, Senegal, Chile and Peru. For more information about Mincon Group PLC, visit Mincon.com.

Industry News, trenchless projects

HDD with Fusible PVC® pipe saves Commission $200,000

Overview

Overview

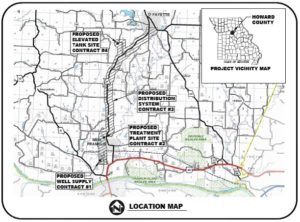

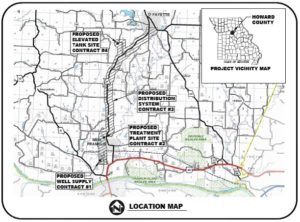

The Howard County Regional Water Commission (HCRWC) was formed in April 2008 with the intent of being a wholesale water provider for the City of New Franklin, the City of Fayette and Howard County CPWSD #1. MECO Engineering has been involved with HCRWC since day one in an effort to assist with design and funding of the required infrastructure. The necessary infrastructure consisted of an alluvial well field, water treatment plant, water tower and distribution mains.

The distribution system design consisted of approximately 68,000 feet of 12-inch waterline, 1,200 feet of 10-inch waterline and 1,200 feet of 6-inch waterline with the majority of the pipe to be installed by conventional open-cut installation. However, there was still a significant amount of the 12-inch waterline that could not be installed by conventional open-cut construction

The distribution system design consisted of approximately 68,000 feet of 12-inch waterline, 1,200 feet of 10-inch waterline and 1,200 feet of 6-inch waterline with the majority of the pipe to be installed by conventional open-cut installation. However, there was still a significant amount of the 12-inch waterline that could not be installed by conventional open-cut construction

based on environmental concerns such as creek crossings or as a result of private property disturbance agreements tied to the issuance of easements. As a result, approximately 8,800 feet of the 12-inch line would need to be installed using horizontal

directional drilling (HDD) installation methodology.

The original plans and specifications included HDPE pipe for the HDD portions of the job. However, during the bid process, Fusible PVC® pipe was allowed as an alternate material for the HDD sections. As a benefit, Fusible PVC® pipe would be able to match the bell-and-spigot PVC pipe being installed in the open cut portions of the job, while the HDPE pipe would need to be upsized in order to provide the same inside diameter. Ultimately the project allowed for two material options in the HDD portion of the job, 12-inch DR 21 Fusible PVC® pipe and 14-inch DR 9 HDPE pipe.

Bids were opened on July 8, 2015 and based on utilizing Fusible PVC® pipe for the HDD sections, C&S Construction out of New London, Missouri was the low bidder. In fact, their bid provided a $200,000 savings due to installing Fusible PVC® pipe instead of the HDPE pipe that was originally specified.

The distribution system portion of the work lasted approximately eight months with all of the Fusible PVC® pipe being installed and tested without any issues.

“We have installed Fusible PVC® pipe on multiple jobs. We really like the way it performs. For this project it allowed us to drill a smaller hole when compared to the HDPE option. Since most of these drills occurred in rock, a smaller hole provides substantial savings of both time and money.” Clinton Ray, Owner Ray’s Construction

Project Story submitted by Underground Solutions, Inc., 858.679.9551

www.undergroundsolutions.com

Industry News

UKSTT are holding their first Masterclass of 2018 on Polyethylene Lining at the Birmingham Motorcycle Museum in Solihull.

Date: 19th April 2018

Venue: Birmingham Motorcycle Museum | Solihull | West Midlands | B92 0EJ

Programme Highlights include:

- PE Pipe: Materials, Properties, Design and Application

- PE Lining: Methods & Techniques, Applications & Design

- Jointing of PE Lining Pipes

- UK & International Standards & Codes of Practice for PE Pipe Lining – Water, Gas & Wastewater

- Pipe Bursting using PE Lining – Upsizing

- Case Studies

- Sliplining

- Close Fit Fold & Form

- Close Fit Diameter Reduction

The UKSTT Masterclasses qualify for a CPD certificate which is an easy way for you to demonstrate your continued efforts to keep your skills and knowledge up to date. To request a CPD certificate please enquire when booking.

To register your attendance please return the Booking Form to admin@ukstt.org.uk

Cost to attend: £150pp + VAT. UKSTT/FWA & PIG members receive a 10% discount. Price includes:

Tea/Coffee & Biscuits on arrival

Mid Morning Tea/Coffee & Biscuits

Two Course Hot & Cold Buffet Lunch

Afternoon Tea/Coffee & Biscuits

Free entry to the Motorcycle Museum

Copies of the full days presentations

Free wifi

CPD Certificate

Hard Rock Main Beam TBM has achieved a national record for 7 to 8 meter (23 to 26 ft) machines: 1,423.5 m (4,670 ft) in one month. The record tops a previously-set achievement on the same project from earlier in 2017, when the TBM advanced at a rate of 1,336.8 m (4,386 ft) in one month.

Hard Rock Main Beam TBM has achieved a national record for 7 to 8 meter (23 to 26 ft) machines: 1,423.5 m (4,670 ft) in one month. The record tops a previously-set achievement on the same project from earlier in 2017, when the TBM advanced at a rate of 1,336.8 m (4,386 ft) in one month.

The Jilin Lot 3 tunnel, which is being bored as part of a water conservation project, will be 24.3 km (15 mi) long when complete. Under contractor Beijing Vibroflotation Engineering Co. Ltd. (BVEC), the machine has excavated 14 km (8.7 mi) of the tunnel as of January 2018.

The Jilin Lot 3 tunnel, which is being bored as part of a water conservation project, will be 24.3 km (15 mi) long when complete. Under contractor Beijing Vibroflotation Engineering Co. Ltd. (BVEC), the machine has excavated 14 km (8.7 mi) of the tunnel as of January 2018.