Industry News, trenchless people

Purdue welcomes Dan Liotti of Midwest Mole!

Purdue welcomes Dan Liotti of Midwest Mole!

The first NASTT Purdue Student Chapter guest lecture for the 2017-2018 academic year was held on October 19. The guest speaker was Dan Liotti, CEO of Midwest Mole, Inc., who is a Purdue alumnus and the 2015 Trenchless Technology Person of the Year.

The lecture was titled “Trenchless Installation Methods”. The speaker gave a brief review of Auger Boring, Guided Boring, Pipe Jacking, Utility Tunneling and EPB Tunneling. The event also included a discussion with Mr. Liotti about job opportunities in the trenchless market. More than thirty students attended the event.

For more information about NASTT’s Student Chapters, contact NASTT Membership Administrator, Renee Corea.

Industry News

Full-function remote control provides outstanding maneuverability

PELLA, Iowa, October 9, 2017 – The new Vermeer SPX25 vibratory plow is designed for fast and efficient cable/fiber and irrigation system installation. It features a full-function remote control that gives the operator a 360-degree view of the jobsite, helping to avoid potential obstacles and an unobstructed view of the product being installed. The SPX25 vibratory plow is compact, powerful and built with tracks to minimize ground disturbance.

PELLA, Iowa, October 9, 2017 – The new Vermeer SPX25 vibratory plow is designed for fast and efficient cable/fiber and irrigation system installation. It features a full-function remote control that gives the operator a 360-degree view of the jobsite, helping to avoid potential obstacles and an unobstructed view of the product being installed. The SPX25 vibratory plow is compact, powerful and built with tracks to minimize ground disturbance.

“For applications like installing cable or fiber-to-the-home, contractors can face several challenges like narrow gates, fences and common backyard obstacles,” explained Ed Savage, product manager at Vermeer. “The SPX25 plow minimizes those concerns. We’ve eliminated the need for operators to run the machine from behind, which means they can stand in whatever location gives them the best view. This design has also allowed us to make the plow even more compact for excellent performance in tight areas.”

The Vermeer SPX25 vibratory plow is powered by a 25 hp (18.6 kW) Kohler gas engine that provides ample power for installing small pipes and cables at depths up to 12 inches (30.5 cm) and for boring underneath driveways and sidewalks using the optional Porta Bore attachment. The dual rubber tracks with a ground pressure of 3.7 psi (.3 bar) on the Vermeer SPX25 plow delivers great floatation in soft ground conditions and helps reduce jobsite restoration after an install. The lightweight plow offers a quick transport speed of 3.7 mph (6 km/h).

For efficient turning, while installing utilities around obstacles, the SPX25 unit is equipped with a pivot-mounted plow that has a 55-degree swing angle that automatically adjusts when turning.

An optional reel carrier can be mounted to the machine, helping to reduce the amount of jobsite equipment and labor needed on the jobsite. Contractors also have the option of adding a weight kit for added traction when working in hard ground conditions.

For more information about the Vermeer SPX25 vibratory plow, visit Vermeer.com or contact your local Vermeer dealer.

ABOUT VERMEER

Vermeer Corporation delivers a real impact in a progressing world through the manufacture of high-quality tree care, environmental, underground construction, surface mining, and agricultural equipment. With a reputation for durability and reliability, that equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer Corporation, products, the dealer network and financing options, visit Vermeer.com.

Industry News, trenchless people

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, offers comprehensive training programs for new and existing customers on how to use GSSI equipment safely and effectively in the field. Classes are available for the complete range of GSSI products and is conducted by a team of four full time trainers.

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, offers comprehensive training programs for new and existing customers on how to use GSSI equipment safely and effectively in the field. Classes are available for the complete range of GSSI products and is conducted by a team of four full time trainers.

The majority of GSSI’s training classes are taught at its headquarters in Nashua, New Hampshire. This facility has two classrooms equipped with computers for students to use and two hands on training areas featuring an indoor utility test pit. For customers located on the West Coast, GSSI offers classes six weeks a year in Henderson, Nevada. All of the classes are complimentary during the initial two year warranty period and can be taken for a fee if students haven’t purchased equipment or are outside of the warranty period. Classes in Nashua and Henderson range from one to three days depending on the particular class.

In addition to the regularly scheduled classes in Nashua and Henderson, GSSI offers live online webinars and on-site training for customers who cannot travel to attend a class. On-site training classes are provided at a customer’s facility upon request and can be customized or cover the standard material.

Most classes are geared towards the basic learner, but advanced classes are available for those who have at least six months of experience working with the equipment. Training courses generally require no prerequisites, no prior experience with the equipment or technology. GSSI trainers are skilled at teaching users of all educational and skill levels. For advanced users and those looking to drill deeply into the technology, GSSI can add any additional training or engineering resource.

“GSSI has invested a tremendous amount of time and money into developing a superior training program. GSSI focuses on partnering with its customer to make sure they are successful and training is an important part of that partnership,” said Dan Welch, GSSI Training Manager.

The class schedule is posted on the GSSI website so students can select the class and date that meets their needs. Popular offerings include classes on BridgeScan, RADAN 7, RoadScan, StructureScan Mini XT, StructureScan Pro and UtilityScan.

For more information on the GSSI training program, visit http://www.geophysical.com/training.htm.

Industry News, trenchless projects

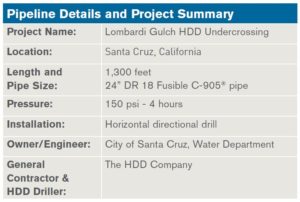

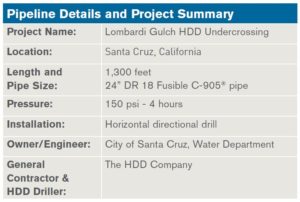

SANTA CRUZ ACCOMPLISHES EMERGENCY HORIZONTAL DIRECTIONAL DRILL FOR

LOMBARDI GULCH CROSSING

HDD provides a rapid and reliable way to replace aging steel pipeline

Overview

Overview

The City of Santa Cruz Water Department (SCWD) has long anticipated the need to assess, design and build a new pipeline system as part of the existing North Coast System (NCS) which delivers raw water to their water treatment plant. The existing NCS is a series of stream diversion structures and collection

conduits and includes approximately 16 miles of pipelines that are nearing, or have exceeded, their design life and must be replaced. The replacement pipeline is a series of phased projects and will provide a water delivery system that will be reliable for the next fifty years or more.

Phase 3 of the overall initiative included the replacement of 18,600 feet of primarily 24-inch diameter pipe using open cut methodology. Additionally, five trenchless crossings, one horizontal directional drill (HDD) crossing under sensitive environmental habitats and four horizontal auger bores crossing under California Department of Transportation and railroad right-of-ways were included in Phase 3.

Phase 3 of the overall initiative included the replacement of 18,600 feet of primarily 24-inch diameter pipe using open cut methodology. Additionally, five trenchless crossings, one horizontal directional drill (HDD) crossing under sensitive environmental habitats and four horizontal auger bores crossing under California Department of Transportation and railroad right-of-ways were included in Phase 3.

In 2015, this phase of the NCS project had been designed but had not gone out to bid when a failure of a 1,200-foot critical section of the existing steel pipeline at the Lombardi Creek Crossing location prompted SCWD to schedule that section for immediate replacement. Site conditions at this location required replacing the pipeline using HDD installation methodology. Its location within the Wilder Ranch State Park elevated environmental concerns because the park has strong biological, scenic, cultural and recreational values.

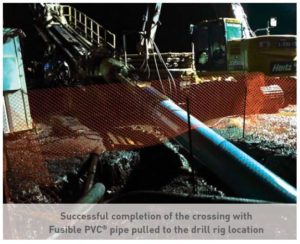

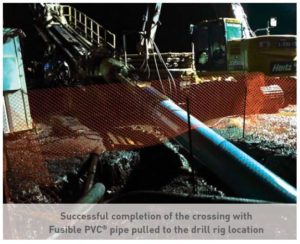

The replacement of the Lombardi Creek crossing began in late 2015 after selecting the HDD Company from Granite Bay, California to be the contractor. The actual drill alignment length was approximately 1,300 feet with an elevation change of approximately 60 feet. Entry and exit angles were approximately 10 degrees. The final alignment was 25 feet below the bottom of the creek. 24-inch DR 18 Fusible PVC®

The replacement of the Lombardi Creek crossing began in late 2015 after selecting the HDD Company from Granite Bay, California to be the contractor. The actual drill alignment length was approximately 1,300 feet with an elevation change of approximately 60 feet. Entry and exit angles were approximately 10 degrees. The final alignment was 25 feet below the bottom of the creek. 24-inch DR 18 Fusible PVC®

pipe was selected as the replacement pipe. Overall, the drill alignment and bore preparation took four weeks. While the bore hole was being drilled and reamed, the Fusible PVC® pipe was fused by Underground Solutions. Once the bore hole was prepared, the Fusible PVC® pipe was pulled into place,

a process that took approximately 8 hours. The replacement project took two months from mobilization to pressure test and the replacement pipe was placed into service after completion. This new segment will be tied into the new NCS Phase 3 pipeline when it is complete.

Project Manager Kevin Crossly stated, “The Lombardi Gulch HDD Undercrossing is the largest and longest installation of Fusible PVC® pipe to date for the City of Santa Cruz. The City was very pleased during all phases of the project with Underground Solutions which provided technical support solutions during design of the project. When the City experienced the 0.5 MGD leak and fast tracked the construction phase, Underground Solutions was responsive to the project requirements to secure, fabricate, deliver and fuse the 1,300 LF of pipe that was ultimately installed on a very aggressive schedule of approximately eight weeks. Fusible PVC® pipe is a great product that Underground Solutions will support and stand behind. We will definitely consider using Fusible PVC® pipe on future projects.”

Project Manager Kevin Crossly stated, “The Lombardi Gulch HDD Undercrossing is the largest and longest installation of Fusible PVC® pipe to date for the City of Santa Cruz. The City was very pleased during all phases of the project with Underground Solutions which provided technical support solutions during design of the project. When the City experienced the 0.5 MGD leak and fast tracked the construction phase, Underground Solutions was responsive to the project requirements to secure, fabricate, deliver and fuse the 1,300 LF of pipe that was ultimately installed on a very aggressive schedule of approximately eight weeks. Fusible PVC® pipe is a great product that Underground Solutions will support and stand behind. We will definitely consider using Fusible PVC® pipe on future projects.”

Industry News, trenchless people, trenchless products

Vac-Tron Equipment is excited to introduce Empire CAT as their new Arizona dealer. Vac-Tron partnered with Empire because they share the same common core values and beliefs. “This was a perfect fit and we are honored to have Empire CAT representing our product line.” Brian Showley, VP Vac-Tron Equipment.

Vac-Tron Equipment is excited to introduce Empire CAT as their new Arizona dealer. Vac-Tron partnered with Empire because they share the same common core values and beliefs. “This was a perfect fit and we are honored to have Empire CAT representing our product line.” Brian Showley, VP Vac-Tron Equipment.

“We wanted to partner with a company that shared similar strategies within the markets we serve. Vac-Tron is an industry leader in vacuum excavation and their equipment lends itself to the same clientele that we serve with our excavation lines from Caterpillar. Empire CAT is always looking for ways to offer our customers safer and more efficient products and our partnership with Vac-Tron brings a new level of safety to the jobsite.” Michael Rodoni, Rental Manager for Empire CAT

Empire Southwest, LLC is a third-generation family-owned Caterpillar dealership. Founded in 1950 by Jack Whiteman, Empire sells, rents, and services heavy equipment, tractors, and power generation equipment to contractors throughout Arizona.

Empire is:

- Committed to meeting the needs and supporting the success of clients throughout the mining, agriculture, and construction industries.

- Proud of our business culture, which was built on the Corporate Values of Safety, Respect, Integrity, Teamwork, Excellence, Stewardship, and Astonishment.

- Dedicated to the success of our clients and the communities we serve.

- Committed to building and maintaining solid business partnerships.

For more information on Empire CAT, please visit www.empire-cat.com.

For more information on Vac-Tron Equipment or to schedule a FREE demo, please visit www.vactron.com or call 1-888-VAC-TRON.

Industry News, trenchless products, trenchless projects

First of Two Mixed Ground Machines will begin boring this autumn

Singapore industrial photographer service

The first of two Slurry TBMs, a rebuilt 6.65 m (21.8 ft) diameter machine, passed its factory acceptance on September 4, 2017 in Singapore. The machine, fitted with a Robbins cutterhead and outer shields, is destined for the Mumbai Metro Line 3 under contract UGC03 for the Dogus-Soma JV (DSJV), and will begin excavation in late 2017. The factory acceptance for a second 6.65 m (21.8 ft) diameter Slurry TBM will be conducted by the end of 2017.

The on-time delivery of the first machine is just the beginning of partnership that will span years. “There are few companies in the international arena that are as professional as Robbins. Robbins has been very helpful to DSJV since the inception of the project and will be our partners until the end of the contract. Robbins’ presence in India including field service crews will be a great help for us in future,” said Mr. DV Raju, Senior Vice President for SOMA.

Singapore industrial photographer service

The two machines will excavate parallel 3.5 km (2.2 mi) long tunnels between Mumbai Central and Worli station sites, passing through three intermediate cut and cover stations on the way. Ground conditions consist of fresh to weathered basalt and breccia up to 100 MPa UCS with water pressures up to 3 bar.

The JV selected Slurry machines for their contract due to the challenging ground conditions expected. “I have worked with Slurry TBMs on similar geology globally. Slurry TBMs have real power and will suit the hard rock geology of our Mumbai Metro contract 3. The water table and variable geology, especially basalt of higher hardness, can be easily tackled by Slurry TBMs,” said Mr. Tamay Sayin, Project Manager for DSJV. The cutterheads of the machines are fitted with wear protection, wear detection bits, and Robbins 17-inch disc cutters for the conditions. Grizzly bars will limit the size of boulders that can enter the cutterhead to 250 mm (9.8 in). The slurry systems includes rock crushers as well as abrasion-resistant plating in high-wear areas.

Singapore industrial photographer service

The two TBMs are the first of a total of four machines being provided by Robbins for the Mumbai Metro Line 3. Another two 6.65 m (21.8 ft) diameter Crossover XRE machines will bore parallel 2.8 km (1.7 mi) tunnels on a separate contract in 2018. “Mumbai Metro is one of the most prestigious metro works in the country, and Robbins’ involvement in providing suitable machines and associated services is an honor,” said Kapil Bhati, Managing Director for Robbins India.

The 33.5 km (20.8 mi) long Line 3 of Mumbai Metro being constructed by the Mumbai Metro Rail Corporation (MMRC) will consist of 26 underground stations and one at-grade station that will reduce heavy traffic and rail congestion between Bandra and Churchgate areas of the city. A total of 17 TBMs are being procured to bore various sections of the tunnels, which will be excavated at average depths of 15 to 25 m below the city. The entire line is expected to be operational by 2021.

Image 1: Officials from Robbins, owner MMRC, contractor Dogus-Soma JV, and consultant Maple celebrate the successful factory acceptance testing of a Slurry TBM bound for the Mumbai Metro on September 4, 2017.

Image 2: (From left to right) Mr. DV Raju, Senior Vice President-SOMA, Mr. Kapil Bhati, Managing Director-Robbins India, and Mr. Tamay Sayin, Project Manager-DSJV mark the occasion of the first Robbins TBM to be sent to India’s Mumbai Metro Line 3 project.

Image 3: The Slurry machine is the first of four Robbins TBMs that will be supplied to Mumbai Metro, including two Crossover XRE machines to be supplied to another contract in 2018.

Purdue welcomes Dan Liotti of Midwest Mole!

Purdue welcomes Dan Liotti of Midwest Mole!