Industry News, trenchless people

Zahra (Ellie) Kohankar Kouchesfehani is a Ph.D. Student and Graduate Research and Teaching Assistant at the Center for Underground Infrastructure Research and Education (CUIRE) in the Department of Civil Engineering at The University of Texas at Arlington. She is a NASTT Student Chapter Member and a valuable volunteer at our annual No-Dig Show.

Zahra (Ellie) Kohankar Kouchesfehani is a Ph.D. Student and Graduate Research and Teaching Assistant at the Center for Underground Infrastructure Research and Education (CUIRE) in the Department of Civil Engineering at The University of Texas at Arlington. She is a NASTT Student Chapter Member and a valuable volunteer at our annual No-Dig Show.

We are excited that Zahra’s submission, “Structural Design Methodology for Spray Applied Pipe Liners in Gravity Storm Water Conveyance Conduits as a Trenchless Renewal Application,” has been selected for an ISTT 2019 No Dig Award.

The selection team found the methodology to be a significant contribution to the trenchless world.

The award will be recognized at the Gala Dinner and Awards Ceremony on October 1, 2019 at the 37th International No Dig Conference in Florence, Italy.

Congratulations, Zahra!

Industry News, trenchless people

Longtime underground construction and trenchless industry professional Davis Yates passed away Tuesday, July 2, 2019 at the age of 51. Through his career Yates worked at trenchless equipment manufacturer TT Technologies, Aurora, Ill., Mocon Corp., Southern California HDPE pipe, fitting and fusion supplier Maskell-Robbins, as well as a variety trenchless and underground contractors along the West Coast.

Longtime underground construction and trenchless industry professional Davis Yates passed away Tuesday, July 2, 2019 at the age of 51. Through his career Yates worked at trenchless equipment manufacturer TT Technologies, Aurora, Ill., Mocon Corp., Southern California HDPE pipe, fitting and fusion supplier Maskell-Robbins, as well as a variety trenchless and underground contractors along the West Coast.

Yates trained many people throughout his career in the proper use of various boring, tools, pipe rammers and pipe bursting systems. He was an energetic and innovative individual whose way of getting the job done was very much appreciated by those he worked with over the years.

Always an innovator, always creative and always seeing the job through, he became great friends with many of the people he worked with in the field and will be missed by many.

Yates leaves behind two children, Jenna, 13 and Marcus, 11. A Go Fund Me page has been established to help with the expenses of his children’s future education, as well as the planting of a remembrance tree. Donations will be placed into a savings plan for both Jenna and Marcus.

The Go Fund Me Page can be found here: https://www.gofundme.com/f/jenna-and-marcus-dad

Industry News, trenchless people

PELLA, IA – Recently, Vermeer Corporation held the groundbreaking for a monument commemorating the buildings destroyed by an EF3 tornado last July (2018), while celebrating the strength of the Vermeer team and the growth and progress that is happening along the Vermeer Mile.

PELLA, IA – Recently, Vermeer Corporation held the groundbreaking for a monument commemorating the buildings destroyed by an EF3 tornado last July (2018), while celebrating the strength of the Vermeer team and the growth and progress that is happening along the Vermeer Mile.

“The tornado was the greatest challenge Vermeer has ever faced. I am incredibly proud to say our team has turned it into an opportunity. Not only are we rebuilding what we had, but we’re becoming stronger than ever before,” said President and CEO Jason Andringa.

With three new facilities underway at the Pella-based headquarters, Vermeer is investing heavily in the future.

The first facility scheduled to open this summer is a new engineering and R&D building named Shop 48. The name stems from Founder Gary Vermeer’s shop where his innovations came to life and led to the founding of Vermeer Corporation in 1948. With more than 100,000 square feet of space dedicated to building and testing new equipment, team members will begin to move into this space in August.

“We’re very fortunate at Vermeer to have a 71-year history of innovation. Shop 48 will take our innovation and growth opportunities long into the future,” said President of Industrial Solutions Doug Hundt.

Plant 7 was formally announced as the new facility being built where Plants 5 & 6 once stood. Nearly 500,000 square feet of manufacturing and office space will expand beyond the original manufacturing footprint that took up just less than 400,000 square feet of this area. The new facility will connect to the original Plant 7 that was damaged in the tornado but repaired in the months following. Together, they will take on the name Plant 7. Scheduled to be completed in fall 2020, this facility is being built to keep team members safe at every touchpoint on the job, create ultimate productivity, be a collaborative and engaging space for team members and allow for growth long into the future. Incorporating advanced manufacturing techniques and continuous improvement best practices will help drive world-class manufacturing. “Looking ahead, this facility is going to be world-class in every feature. We’re advancing our paint technology, coat technology and the space for our team,” said Vice President of Operations Bill Blackorby.

Also recognized was the new Eco Center. Replacing the one lost in the tornado, the new building will be placed behind Plant 1 and open its doors in January 2020. The Eco-Center helps responsibly process and manage waste along the Mile.

“Our customers depend on our ability to get high-quality equipment to them – this new facility makes us excited to continue to deliver on this promise into the future,” said Executive Vice President of Forage and Lifecycle and Chief Marketing Officer Mark Core.

About Vermeer Corporation

Vermeer delivers a real impact in a progressing world through the manufacture of high-quality agricultural, underground construction, surface mining, tree care and environmental equipment. With a reputation for durability and reliability, that equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer, products, the dealer network and financing options, visit Vermeer.com.

Industry News, trenchless people

The NASTT Trenchless Family has lost friend and colleague, Tom Perry, a member of the Northeast Regional Chapter Board of Directors.

The NASTT Trenchless Family has lost friend and colleague, Tom Perry, a member of the Northeast Regional Chapter Board of Directors.

Thomas Perry of Mt. Olive Township, NJ passed away Friday July 26, 2019 at Morristown Medical Center in Morristown after a short illness. He was 58.

Tom was born in Pequannock, NJ and lived in Mt. Olive Township for 21 years.

A graduate of Pequannock High School and Montclair State University, Tom was the owner of Multi Utilities Ventures in Mt. Olive Township.

Beloved husband of Jean (nee: Miller) Perry. Devoted father of Erin and Megan Perry. Loving son of Doris (nee: Peacock) Perry and the late Raymond Perry. Dear brother of Jim Perry, Peggy Perry, Doreen Sprules , Mary Beth Wyant , Jean Wallace, Michele Bucek, the late Lee Perry, Ricky Perry, Linda Perry and Janice Moebius. Also survived by many nieces and nephews.

We would like to extend our condolences to the Perry Family and to the many friends in our industry that loved Tom.

Memorial donations may be made to the National Pancreatic Cancer Fund, PO Box 1848, Longmont, CO 80502.

Industry News, trenchless people

The trenchless industry lost a founding member with the recent passing on July 8 of James (Jim) Barbera at the age of 79. James Barbera founded Barbco Inc. in 1989. Today, the company leads the auger-boring industry with equipment that promotes safety and efficiency, such as the TriBor, Flexbor and Pathfinder.

The trenchless industry lost a founding member with the recent passing on July 8 of James (Jim) Barbera at the age of 79. James Barbera founded Barbco Inc. in 1989. Today, the company leads the auger-boring industry with equipment that promotes safety and efficiency, such as the TriBor, Flexbor and Pathfinder.

In November of last year, the Trenchless Technology Center (TTC) at Louisiana Tech University honored James and his brother Leo with lifetime achievement awards for their contributions to the trenchless industry. During the award celebration TTC also unveiled the Barbera Underground Infrastructure Research and Training (BUIRT) Facility. Named in honor of the Barbera family, this state-of-the-art facility will offer research, training and development for the trenchless technology industry.

Barbco has been a generous supporter of NASTT and the trenchless industry throughout the years and their involvement has been very important to us. We send our condolences to the Barbera Family and the team at Barbco.

Image: Jim Barbera and his wife Fran

trenchless people, trenchless projects

When a municipality puts out an RFQ for an engineering project and includes the following words—design a temporary sanitary sewer bypass system as needed to construct improvements—design engineers need to focus on two tasks: defining the scope and designing the solution. But typically, sewer bypass is just one part of a much larger project, and often design engineers aren’t trained in sewer bypass design. Fortunately, you can ask for help from bypass subcontractors and rental companies. That way, when your engineering firm helps the municipality take the project out for bid, estimators will be working with solid information that will help ensure reasonable bids.

The goal is to scope and design quickly, accurately, and effectively to avoid expensive mistakes and delays. Read on for a how-to guide to help you get it right.

Define the Scope

Before listing the steps to define the scope, let’s define what project scope actually means.

Projects are time-constrained undertakings to produce a product, service, or result. The scope defines the purpose, the ultimate goal, and how you will achieve it. Scope also determines the boundaries—what’s included in the project and what’s not. If you fail to define scope adequately, your project will likely end up over budget and behind schedule.

According to the Project Management Institute, scope changes are the single biggest reason projects fail. If the scope becomes a moving target, you’re increasing the chance for the project and your career to take a nosedive.

Here are six steps to help you thoroughly define the project scope.

- Provide an overall project description. The project description should include what the municipality wants to accomplish, the current sewer capacity, equipment in use, location and layout of existing facilities, and duration of the project. You may also want to note challenges, such as existing buildings, roads, and other structures, or areas of environmental concern such as creek crossings.

- Explain the driving forces. Billions of dollars in federal aid have been made available to rehabilitate decaying sewer systems. Many municipalities have taken advantage of the funds to initiate rehabilitation projects, whether for sewer lines, lift stations, or wastewater treatment plants. Or the municipality may be working under a consent decree that mandates specific improvements to a sewer system by a deadline.

- Specify the deliverables. The municipality’s requirements may list the details of sewer system improvements. But often the sewer bypass system itself simply directs you to design a system that will allow the improvements to be made without an interruption of service. It’s up to you to determine the requirements and provide the specifications.

- Determine the boundaries. Based on the improvements the municipality intends to make, you’ll need to determine exactly what the sanitary sewer bypass system should look like to meet the sewer requirements for as long as the project is active. For example, you’ll need to determine if the temporary system must operate at all times during construction, if it can be tied into the existing sanitary sewer system overnight, if the existing sanitary sewer system can be returned to normal flow for long periods, and if the flow can be partially diverted or must be fully diverted.

- State your assumptions. Define the conditions you’re assuming and their impact on the project. For example, the municipality may claim sandy soil in an area. If it’s actually rocky, you’ll be less productive while dealing with unexpected soil conditions. That will impact project time and cost, and generate a change order.

- List uncertainties and potential impacts. Uncertainties create risk and cost money. For example, you need to know up front of any time limitations on when work can be performed to complete the project. You also need to be aware of physical obstructions such as rivers and streams, railroad crossings, parks, and public and private property the sewer bypass may need to cross.

Design the Solution

Your bypass system design needs to be as detailed as possible, or you risk change orders, higher costs, and a damaged reputation. You may want to rely on a bypass subcontractor and/or rental company to help you specify accurately. In addition, technology continues to evolve, and the design should allow the project to meet the highest standards at the lowest cost in the shortest amount of time.

If you’ve established a partnership with a company with expertise in designing sewer bypass systems, you’re a step ahead. You can provide the known parameters to the bypass subcontractor or pump rental company and receive a sewer bypass design in return. For parameters that the municipality can’t provide, your partner can go on site and fill in missing pieces of engineering data to ensure the designed system will operate as intended. A bypass subcontractor will typically provide you with a quote up front, but you normally won’t receive the engineering submittal until after you sign a contract. The engineering submittal and drawings should show exactly how they’ll perform the project and what assumptions they’ve used to make calculations. You can take that back to the municipality for confirmation.

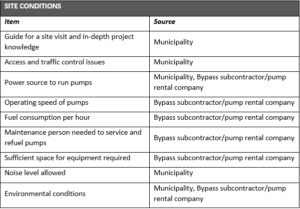

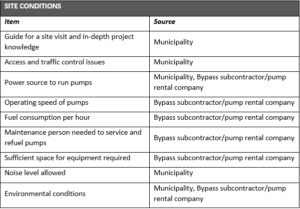

To keep your plans for a sewer bypass on point, here’s a list of the key requirements and where you can get the information to specify them.

We hope this guide will help you better define the scope and design the solution for sewer bypass projects. But you don’t have to go it alone. It helps to work with a partner that can not only provide high-quality equipment and accessories, but engineering knowledge and installation expertise.

Interested in learning more? Join Sunbelt Rentals for a free webinar with Trenchless Technology on August 15, 2019 at 2 pm EST. Register here

Zahra (Ellie) Kohankar Kouchesfehani is a Ph.D. Student and Graduate Research and Teaching Assistant at the Center for Underground Infrastructure Research and Education (CUIRE) in the Department of Civil Engineering at The University of Texas at Arlington. She is a NASTT Student Chapter Member and a valuable volunteer at our annual No-Dig Show.

Zahra (Ellie) Kohankar Kouchesfehani is a Ph.D. Student and Graduate Research and Teaching Assistant at the Center for Underground Infrastructure Research and Education (CUIRE) in the Department of Civil Engineering at The University of Texas at Arlington. She is a NASTT Student Chapter Member and a valuable volunteer at our annual No-Dig Show.