Uncategorized

Robust Rock Machine completes long-awaited water tunnel in Montreal

In a large November 2015 ceremony attended by the mayor of Montreal, Quebec, Canada,  and representatives from local media outlets, the Rosemont Reservoir tunnel construction came to a close. The long-awaited project, more than 38 years in the making, gave good cause for celebration as crew members crowded around the cutterhead of the 3.0 m (9.8 ft) diameter Double Shield TBM that had emerged into an exit shaft.

and representatives from local media outlets, the Rosemont Reservoir tunnel construction came to a close. The long-awaited project, more than 38 years in the making, gave good cause for celebration as crew members crowded around the cutterhead of the 3.0 m (9.8 ft) diameter Double Shield TBM that had emerged into an exit shaft.

Local contractor Foraction, Inc., headed the excavation of the 4.0 km (2.5 mi) long tunnel with a TBM launch in December 2014. Roger Lepinay, Equipment Manager for Foraction, Inc., praised the Robbins disc cutter wear in both limestone and harder rock formations: “I was impressed by the cutters, it was a nice surprise. They were quite long-lasting compared to other cutters I have used on jobs in the past.”

Lepinay characterized the ground as “almost ideal”, with a few difficult sections. “Below  Montreal there is mostly thinly bedded limestone, with some shale and intrusive igneous dykes,” explained project geologist Brigitte Gagné for company Exp Service Inc. While the limestone averaged 100-150 MPa UCS, rock in the intrusives ranged from 100-300 MPa. The dykes were as small as 1 m (3.3 ft) wide and as large as 100 m (328 ft). The contractor was able to successfully navigate these sections despite the varying rock strengths. Even with geologic challenges including some water inflows and over-break in small sections, the contractor was able to achieve advance rates of up to 38 m (125 ft) per day in two shifts of 9.5 hours each. Much of the ground was self-supporting, though the contractor installed rock bolts every 2.5 m (8.2 ft) into portions of the tunnel crown, while mesh, rock bolts, and steel sheets were used in the sections of unstable rock.

Montreal there is mostly thinly bedded limestone, with some shale and intrusive igneous dykes,” explained project geologist Brigitte Gagné for company Exp Service Inc. While the limestone averaged 100-150 MPa UCS, rock in the intrusives ranged from 100-300 MPa. The dykes were as small as 1 m (3.3 ft) wide and as large as 100 m (328 ft). The contractor was able to successfully navigate these sections despite the varying rock strengths. Even with geologic challenges including some water inflows and over-break in small sections, the contractor was able to achieve advance rates of up to 38 m (125 ft) per day in two shifts of 9.5 hours each. Much of the ground was self-supporting, though the contractor installed rock bolts every 2.5 m (8.2 ft) into portions of the tunnel crown, while mesh, rock bolts, and steel sheets were used in the sections of unstable rock.

The long tunnel drive at small diameter was carefully planned to optimize logistics. The  contractor utilized a muck train that could accommodate two pushes worth of excavated material. The first kilometer (0.6 mi) was ventilated from the launch shaft, while three surface-driven 800 mm (32 in) diameter surveying wells at the 1, 2, and 3 km (0.6, 1.2, and 1.9 mi) marks ventilated the rest of the tunnel as the TBM progressed.

contractor utilized a muck train that could accommodate two pushes worth of excavated material. The first kilometer (0.6 mi) was ventilated from the launch shaft, while three surface-driven 800 mm (32 in) diameter surveying wells at the 1, 2, and 3 km (0.6, 1.2, and 1.9 mi) marks ventilated the rest of the tunnel as the TBM progressed.

With the breakthrough, an important phase of the Rosemont Reservoir project is complete. The reservoir itself was built in 1960 to increase water supply to the city and a geotechnical study for the tunnel was carried out in 1977. However, other major infrastructure projects soon took priority and the project was placed on hold. By 2010, the population of the city had increased dramatically and problems with the existing reservoirs put the project back on the fast track. The large reservoir that sat idle for decades will now be used to improve much of the city’s water supply.

As of mid-January the contractor is working to ready the tunnel for installation of the carrier  pipe, consisting of 2.13 m (84 in) I.D. pre-stressed concrete cylinder pipe (PCCP). Crews will then grout the pipe in place in preparation for the Rosemont Reservoir to come online.

pipe, consisting of 2.13 m (84 in) I.D. pre-stressed concrete cylinder pipe (PCCP). Crews will then grout the pipe in place in preparation for the Rosemont Reservoir to come online.

Image 1: The 3.0 m (9.8 ft) diameter Robbins Double Shield TBM bored a 4 km (2.5 mi) tunnel below downtown Montreal, Quebec, Canada.

Image 2: Workers climb through the cutterhead of the Robbins TBM to mark the breakthrough in November 2015 at a large ceremony.

Image 3: The mayor of Montreal, Denis Coderre, speaks to local media at the November ceremony for the Rosemont Reservoir tunnel breakthrough.

Image 4:The crew of Foraction, Inc. and Robbins gathers around the Double Shield TBM to celebrate the tunnel completion.

Uncategorized

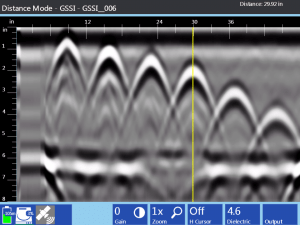

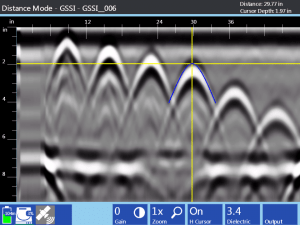

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, will be showcasing its latest GPR technology at the 2016 World of Concrete conference, to be held February 2-5, 2016, at the Las Vegas Convention Center in Las Vegas, Nevada, Booth # C4156. New technology to be featured includes the StructureScan Mini XT handheld GPR, as well as a 3D module for GSSI’s SIR® 4000 GPR control unit, which features numerous updates that support next-generation digital capabilities.

showcasing its latest GPR technology at the 2016 World of Concrete conference, to be held February 2-5, 2016, at the Las Vegas Convention Center in Las Vegas, Nevada, Booth # C4156. New technology to be featured includes the StructureScan Mini XT handheld GPR, as well as a 3D module for GSSI’s SIR® 4000 GPR control unit, which features numerous updates that support next-generation digital capabilities.

GSSI experts will be highlighting the new StructureScan Mini XThandheld GPR, the latest addition to the industry standard StructureScanall-in-one GPR system. Ideal for locating rebar, conduits, post-tension cables and voids, the StructureScan Mini is also used for real time determination of concrete slab thickness. Its compact design has long made the StructureScan Mini a favorite among concrete inspection professionals, especially in tight spaces or overhead survey locations. Drop by the booth to see the newest model, which features a friendly user interface and several new data collection modes. Additionally, the redesigned model is IP 65 rated- to withstand the jobsite’s toughest conditions.

Also on display will be the standard StructureScan Mini, whose 1600 MHz antenna can reach depths of up to 50 centimeters (20 inches).All the StructureScan Mini systems safely locate metallic and non-metallic targets, with an auto target feature that marks the features of interest. The systems are available with standard 2D capabilities, or with 3D capabilities for an x-ray-like image. The units’ ruggedized plastic casing and wheels ensure long-lasting performance.

The updated SIR 4000 GPR control unit on display features a variety of updates, including a new 3D functionality for Expert Mode that promises to revolutionize how three-dimensional GPR data is visualized, while simplifying an often complicated process. The controller’s innovative technology is compatible with both GSSI’s traditional analog antennas and newest digital offerings, resulting in the versatility and flexibility needed to support a wide range of users and applications.

The SIR 4000 updates also brings the StructureScan 2D and 3D collection modes to the controller, streamlining its use for the concrete construction industry. The module includes high frequency antenna-specific set-ups to ensure survey efficiency, and enables the controller to automatically recognize smart antenna set-ups. The updates also include an on-the-fly automatic gain option to better enhance the data display, while still saving the file in the original raw format for post processing. Also included is a horizontal zoom function that helps resolve smaller targets, and a “Save Image” shortcut for quick reports.

The updated SIR 4000 provides a 10.4 inch high definition display, a simple user interface, plug-and-play GPS integration, and multiple data transfer options. Designed with a number of exclusive features, the SIR 4000’s casted aluminum chassis offers superior temperature stability and an impact resistant design. The unit delivers a full IP 65 capability, and can withstand tough jobsite conditions.

Uncategorized

AURORA, IL. – TT Technologies recently introduced new downhole tooling for its Grundodrill 4X compact HDD rig. The new tooling improves safety and simplifies drilling operations by allowing users to quickly and safely disconnect the sonde housing segment from the drill string after the pilot bore is complete. The system is comprised of a specially designed sub saver and clamp that locks into place and allows the operator to easily and quickly disengage the sonde housing without the use of pipe wrenches.

compact HDD rig. The new tooling improves safety and simplifies drilling operations by allowing users to quickly and safely disconnect the sonde housing segment from the drill string after the pilot bore is complete. The system is comprised of a specially designed sub saver and clamp that locks into place and allows the operator to easily and quickly disengage the sonde housing without the use of pipe wrenches.

The compact Grundodrill 4X is designed for residential service, small diameter main installations and “last mile” operations, offering 9,800 lbs. of thrust and pullback. Using the compact drill is less intrusive and ideal for areas where larger units are not an option. The Grundodrill 4X also comes with the exclusive Smart Vice system that performs vice cycling operations automatically.

Uncategorized

District developing a long-range water plan to maximize assets

Broomfield, Colo., Jan. 13, 2016 – After a two-year study conducted by MWH Global and Hawksley Consulting, Castle Pines North Metropolitan District has decided on a long-range water plan that ensures the future of enduring water supplies to the District.

“The business of providing water to our residents in Castle Pines has become increasingly challenging. It’s not enough to own multiple water assets. We have to position ourselves in a way that gives us durable, sustainable and renewable water supplies to replace those from non-renewable groundwater sources,” said District Manager Jim Nikkel.

The District enlisted the help of Colorado-based engineering, consulting and construction firm MWH and its subsidiary, Hawksley Consulting for a study focusing on solutions that maximized the value and use of the District’s water assets. In addition, the firm determined a plan that reduces reliance on groundwater from wells and builds infrastructure to support a renewable water supply from snow and rainfall.

The District’s water plan was designed for strategic utilization of Lower South Platte water rights, Plum Creek and Hock Hocking water rights, as well as storage in Chatfield Reservoir. Nikkel said the plan achieves a meaningful goal.

“The plan we received from Hawksley Consulting will allow us to maximize our existing investments, replace up to 97 percent of our groundwater supplies, and cost us about half as much as we had originally estimated,” Nikkel said. He added, “In the first phase of the plan, we’ll have a renewable water supply of 900 acre-feet (AF) per year, or 50 percent renewable. This puts our community in a great position for our future water needs.”

Board President Keith Dodd, added, “Not just the current board, but previous boards have been diligent in working toward reducing our reliance on groundwater. Those sources aren’t always going to be enough for our community. We have a responsibility to protect what’s ours.”

Within the next three to five years, the initial phase of the District’s plan involves storage of renewable water in Chatfield Reservoir, through the Chatfield Reallocation Project. Nikkel says from that point, it will be a continual effort to bring assets on line.

“Our customers trust us to put the investment we’ve made to work. We’re doing that, by implementing the findings from Hawksley Consulting, developing the infrastructure, and continuing to assess our community’s long-range water needs,” Nikkel said.

About MWH Global

MWH Global is dedicated to Building a Better World. As specialists in water and natural resources, MWH employees use innovative ideas and technology to help solve complex infrastructure and environmental challenges. This work is built on a nearly 200-year history during which MWH has delivered services from initial planning and design through construction, start-up and operations. Today, MWH employs approximately 7,000 experts including engineers, consultants and construction professionals in 35 countries on six continents. Each of these experts is committed to serving global communities through sustainable development and project delivery. MWH is a private, employee-owned company headquartered in Broomfield, Colorado. For more information, visit www.mwhglobal.com or connect via Twitter, Facebook and LinkedIn.

About Hawksley Consulting

Hawksley Consulting builds on a rich legacy of innovation and impactful solutions to provide answers for our clients’ greatest challenges. Our management consultants throughout the U.S., U.K., Australia, New Zealand and the Middle East bring together global expertise in strategy, finance, risk management, asset management, organizational development, information technology, stakeholder engagement, and environmental and social sustainability. We implement practical solutions for public and private clients in the water, wastewater, energy, transportation, industrial and government sectors. Hawksley Consulting is a wholly-owned subsidiary of MWH Global, the leader in water and natural resources dedicated to Building a Better World. For more information, visit hawksley.com or connect with us on Twitter and LinkedIn.

Uncategorized

Important Updates Alter Sewer Main Condition Assessment and Recommends New Standards for Accepting Post-Rehabilitation Projects

Sacramento, Calif. – January 11, 2016 – a leading provider of smart water leak detection  technologies and cloud computing applications, announced that its patented technology has been prominently featured in a new edition of the industry’s leading wastewater collection manual – OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS, VOLUME 1, SEVENTH EDITION.

technologies and cloud computing applications, announced that its patented technology has been prominently featured in a new edition of the industry’s leading wastewater collection manual – OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS, VOLUME 1, SEVENTH EDITION.

First published in 1976 with nearly 90,000 copies in print, the OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS manual is used by operators, managers, and consulting engineers, worldwide.

The Seventh Edition was published in December 2015, while the Sixth Edition was published in 2003.

“Our manual was originally designed to allow for self-paced instruction where operators worked at their own speed,” said Ken Kerri, Ph.D., P.E., former Director of the Office of Water Programs, California State University, Sacramento (1965-1997) and Chief Project Consultant until his passing in 2014.

“Once operators started using the manual for home study, we realized that it could serve as a textbook in the classroom,” said Dr. Kerri, who co-authored the section on Electro Scanning Inspection.

Today, the Office of Water Programs is a nonprofit organization operated by University Enterprises, Inc., California State University, providing distance learning programs for the operation and maintenance of drinking water and wastewater facilities.

“We are delighted to see our technology become an integral part of Chapter 4: Inspecting and Testing Collection Systems,” states Chuck Hansen, Chairman, Electro Scan.

Electro Scan’s technology is not only explained in Section 4.4 of the Seventh Edition, but also depicted in numerous illustrations, statistical analyses, and practical applications, in accordance with ASTM F2550-13.

In numerous instances, Electro Scan’s low voltage technology is able to identify and quantify leakage amounts in gallons per minute (GPM), often where defects are not identified by certified closed-circuit television (CCTV) operators or by using other inspection techniques.

Electro Scanning Inspection also provides wet-weather condition assessment information, not available using CCTV inspection, and can be performed year around to help locate sources of sanitary sewer overflows (SSOs) and find defects in newly repaired or relined pipes.

Important updates contained in the Seventh Edition suggest altering the acceptance criteria for rehabilitated pipes using Electro Scanning Inspection to assess the effectiveness of cured-in-place pipe (CIPP), service re-connections, and point repairs, explaining the importance of quantifying pre- and post-rehabilitation inspection results.

Given Electro Scan’s ability to automatically find sources of leaks that are frequently missed by CCTV inspection, the manual suggests using Electro Scanning Inspection first to objectively locate and quantify pipe defects, then using CCTV inspection to document the most severe defects.

In addition to Electro Scanning Inspection (Section 4.4), Chapter 4: Inspecting and Testing Collection Systems also includes an updated section on CCTV Inspection (Section 4.3), Smoke Testing (Section 4.5), and Dye Testing (Section 4.6).

Continues Hansen, former Founder and CEO of Hansen Information Technologies, “It was an honor to contribute to Electro Scanning Inspection at the invitation of Dr. Kerri and share this game-changing technology with operators, managers, consulting engineers, and students.”

Image 1- Mark Grabowski,Vice President and General Manager, Electro Scan Inc. and Dr. Kerri, co-author of Electro Scanning Inspection and former Chief Project Consultant, Office of Water Programs until his passing in 2014.

Image 2- Sixth Edition, Volume 1,

published in 2003.

About Electro Scan

Founded in 2011, Electro Scan develops smart water leak detection instrumentation and cloud computing applications that automatically locate, measure, and report pipe condition assessments for water, sewer, and gas pipelines. The Company is headquartered in Sacramento, California.

Contact

Carissa Boudwin, Tel: +1 916 779 0660, Email: carissa@electroscan.com

Uncategorized

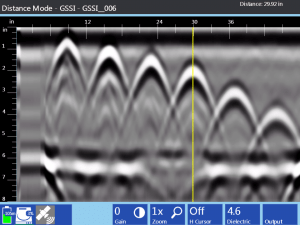

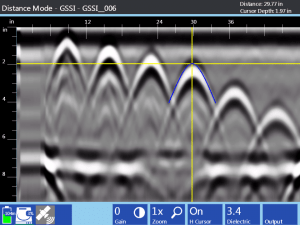

GSSI announces the release of updates to the SIR® 4000 ground penetrating radar (GPR)  control unit. The controller is designed to bridge the legacy of GSSI’s traditional analog antennas with next-generation of digital offerings, giving it the flexibility by supporting a wide range of users in numerous applications. The updates bring the StructureScan 2D collection module to the controller, simplifying its use for the concrete construction industry.

control unit. The controller is designed to bridge the legacy of GSSI’s traditional analog antennas with next-generation of digital offerings, giving it the flexibility by supporting a wide range of users in numerous applications. The updates bring the StructureScan 2D collection module to the controller, simplifying its use for the concrete construction industry.

The StructureScan 2D collection module offers users greater flexibility for using the controller in concrete construction industry applications. The module includes high frequency antenna-specific set-ups to ensure survey efficiency, and enables the controller to automatically recognize smart antenna set-ups.

Additionally, the update offers users the option of on-the-fly automatic gain to better enhance the data display, while still saving the file in the original raw format for post processing. The updated collection module also includes a horizontal zoom function, allowing users to increase the size of the data set up to 8x to resolve smaller targets, and a “Save Image” shortcut for quick reports.

Fully integrated, the SIR 4000 provides a 10.4 inch high definition LED display, a simple user interface, plug-and-play GPS integration, and Wi-Fi enabled data transfer functionality.The SIR 4000 is designed with a number of exclusive features, including a casted aluminum chassis that offers superior temperature stability and an impact resistant design that combined, delivers a full IP 65 rated- able to withstand tough jobsite conditions.

For pricing and availability, please contact your local sales representative.

About GSSI:

Geophysical Survey Systems, Inc. is the world leader in the development, manufacture, and sale of ground penetrating radar (GPR) equipment, primarily for the concrete inspection, utility mapping and locating, road and bridge deck evaluation, geophysics, and archaeology markets. Our equipment is used all over the world to explore the subsurface of the earth and to inspect infrastructure systems non-destructively. GSSI created the first commercial GPR system nearly 45 years ago and continues to provide the widest range and highest quality GPR equipment available today.

and representatives from local media outlets, the Rosemont Reservoir tunnel construction came to a close. The long-awaited project, more than 38 years in the making, gave good cause for celebration as crew members crowded around the cutterhead of the 3.0 m (9.8 ft) diameter Double Shield TBM that had emerged into an exit shaft.

and representatives from local media outlets, the Rosemont Reservoir tunnel construction came to a close. The long-awaited project, more than 38 years in the making, gave good cause for celebration as crew members crowded around the cutterhead of the 3.0 m (9.8 ft) diameter Double Shield TBM that had emerged into an exit shaft. Montreal there is mostly thinly bedded limestone, with some shale and intrusive igneous dykes,” explained project geologist Brigitte Gagné for company Exp Service Inc. While the limestone averaged 100-150 MPa UCS, rock in the intrusives ranged from 100-300 MPa. The dykes were as small as 1 m (3.3 ft) wide and as large as 100 m (328 ft). The contractor was able to successfully navigate these sections despite the varying rock strengths. Even with geologic challenges including some water inflows and over-break in small sections, the contractor was able to achieve advance rates of up to 38 m (125 ft) per day in two shifts of 9.5 hours each. Much of the ground was self-supporting, though the contractor installed rock bolts every 2.5 m (8.2 ft) into portions of the tunnel crown, while mesh, rock bolts, and steel sheets were used in the sections of unstable rock.

Montreal there is mostly thinly bedded limestone, with some shale and intrusive igneous dykes,” explained project geologist Brigitte Gagné for company Exp Service Inc. While the limestone averaged 100-150 MPa UCS, rock in the intrusives ranged from 100-300 MPa. The dykes were as small as 1 m (3.3 ft) wide and as large as 100 m (328 ft). The contractor was able to successfully navigate these sections despite the varying rock strengths. Even with geologic challenges including some water inflows and over-break in small sections, the contractor was able to achieve advance rates of up to 38 m (125 ft) per day in two shifts of 9.5 hours each. Much of the ground was self-supporting, though the contractor installed rock bolts every 2.5 m (8.2 ft) into portions of the tunnel crown, while mesh, rock bolts, and steel sheets were used in the sections of unstable rock. contractor utilized a muck train that could accommodate two pushes worth of excavated material. The first kilometer (0.6 mi) was ventilated from the launch shaft, while three surface-driven 800 mm (32 in) diameter surveying wells at the 1, 2, and 3 km (0.6, 1.2, and 1.9 mi) marks ventilated the rest of the tunnel as the TBM progressed.

contractor utilized a muck train that could accommodate two pushes worth of excavated material. The first kilometer (0.6 mi) was ventilated from the launch shaft, while three surface-driven 800 mm (32 in) diameter surveying wells at the 1, 2, and 3 km (0.6, 1.2, and 1.9 mi) marks ventilated the rest of the tunnel as the TBM progressed. pipe, consisting of 2.13 m (84 in) I.D. pre-stressed concrete cylinder pipe (PCCP). Crews will then grout the pipe in place in preparation for the Rosemont Reservoir to come online.

pipe, consisting of 2.13 m (84 in) I.D. pre-stressed concrete cylinder pipe (PCCP). Crews will then grout the pipe in place in preparation for the Rosemont Reservoir to come online.