Uncategorized

KANSAS CITY, MO–(Marketwired – Apr 3, 2015) – Andy Sauer, P.E., ENV SP, has joined Burns & McDonnell as the Green Infrastructure and Stormwater Leader in the Water division. Sauer is a recognized industry expert in the integration of green infrastructure design in stormwater control systems, with a specialty in stormwater control alternatives in urban environments.

Sauer has served as project manager on a number of high-profile projects in the Midwest that have demonstrated that green infrastructure best management practices (BMP) can be effective, cost-saving options for stormwater control while also providing opportunities for improved community aesthetics.

“We are thrilled to have Andy Sauer join our team,” said Cliff Cate, Wastewater Systems Director for the Burns & McDonnell Water Division. “We’ve long known and admired Andy’s work on a number of projects in our area. He is one of our industry’s leading advocates for green design solutions utilizing native plants, natural materials, permeable surfaces and natural contours of the landscape as a design alternative that often reduces the scale of traditional built infrastructure.”

One of Sauer’s recent projects includes a 281-acre green infrastructure demonstration project as part of Kansas City’s ongoing Overflow Control Program. In addition to his work in Kansas City, Sauer has served in various project management roles for a similar overflow control program for the City of Omaha and as project manager for several projects within Kansas and Missouri.

Sauer has previously served as an adjunct professor at the University of Missouri – Kansas City teaching a graduate course on urban stormwater BMP. He also has served as Chairman of the American Public Works Association (APWA) Kansas City Metro Chapter Water Resources Committee and as project manager for regional BMP training sponsored by the Mid-America Regional Council (MARC). Sauer is a frequent speaker and panelist at professional conferences throughout the country, focusing on design and construction of green infrastructure projects.

Mr. Sauer holds a Bachelor of Science degree in Agricultural Engineering and Master of Science degree in Agricultural and Biological Systems Engineering both from the University of Nebraska-Lincoln. He is a registered professional engineer in the states of Kansas and Missouri and an Envision™ certified professional.

About Burns & McDonnell

Founded in 1898, Burns & McDonnell is a 100-percent employee-owned firm providing engineering, architecture, construction, environmental and consulting services. With 5,000 professionals working in more than 40 regional, national and international offices, Burns & McDonnell offers clients a single source for a range of engineering, design/build, permitting and related services. For more information about Burns & McDonnell, visit www.burnsmcd.com.

SOURCE: Burns & McDonnell

Contact Information

Uncategorized

LMK Technologies joined the Chicago Innovation Award winners, in New York City on  Monday, March 23rd to close the NASDAQ Stock Market, the premier exchange for technology companies. The event, arranged by the Chicago Innovation Awards, emphasizes the surge of innovation that is occurring in the Chicago region, and shines a spotlight on the organizations that make up its vibrant economy.

Monday, March 23rd to close the NASDAQ Stock Market, the premier exchange for technology companies. The event, arranged by the Chicago Innovation Awards, emphasizes the surge of innovation that is occurring in the Chicago region, and shines a spotlight on the organizations that make up its vibrant economy.

“This annual event is an excellent example of how the Chicago Innovation Awards celebrates the spirit of innovation in organizations across all industries, sizes and sectors,” said Tom Kuczmarski, co-founder of the Chicago Innovation Awards.

“We congratulate LMK Technologies for winning the Chicago Innovation Awards, and applaud their commitment to innovation,” said Dan Miller, fellow co-founder.

“We are honored to be part of such an elite group, the Chicago Innovation Awards is a wonderful program that not only supports innovation and creativity but also serves as recognition to the Chicago entrepreneurial community,” stated Larry Kiest, President and CTO of LMK Technologies. Joining Larry at the closing was Mike Reardon, CEO, Greg Norgaard, EVP Sales and Marketing, Jim Conners, CFO and Rick Gage, VP Sales.

LMK was joined by other winners of the 2014 Chicago Innovation Awards, including: 640 Labs, alligatortek, Auctions By Cellular, Beltone, Caremerge, dough, Horizon Pharma, Keeper Security, KENTECH, LuminAID, Mattersight, Options Away, Packback, Pangea, Radio Flyer, Rippleshot, Rise Interactive, Shiftgig, Strata Decision Technology, Swingbyte and ThinkCERCA.

About LMK Technologies

About LMK Technologies

LMK Technologies, a world leader specializing in trenchless methods to renew lateral sewer infrastructure has more than ninety issued patents for its advancements in trenchless technology. Headquartered in Ottawa, IL since 1993, LMK serves the municipal and residential markets through a network of licensed and certified contractors. For more information regarding LMK please visit www.lmktechnologies.com, call 1-815-433-1275 or email info@lmktechnologies.com.

About The Chicago Innovation Awards

The Chicago Innovation Awards, established in 2002, have grown from a single awards ceremony to a year-long series of events and activities designed to celebrate innovation in the Chicago region, educate people and organizations about the principles of innovation, and connect the corners of the economy by building relationships that strengthen companies, grow the economy and create jobs. The organization’s expansion has included formation of the Chicago Innovation Foundation, which promotes innovation education and provides scholarships to college students each year, as well as The Innovators Connection, which connects large companies with Chicago-based start-ups. For more information, visit www.chicagoinnovationawards.com.

Uncategorized

Learn about the latest tools, technologies and techniques to STOP INFILTRATION in Sanitary Sewers at the Avanti MUNICIPAL GROUT SCHOOL – Operator Intensive Training

Industry leaders have teamed-up for this Municipal Grout School to advance the operating standards in one convenient location near Universal Studios in Orlando, FL. Instructors from Avanti, CUES, and Logiball have built this live learning event for one purpose–STOP INFILTRATION. Let it begin with you.

Benefit from classroom presentations, demonstrations and hands-on workshops on the following:

2-DAY OPERATOR INTENSIVE TRAINING

Public Works and Municipal Contractors (April 9-10)

- Solution Grouts for Municipal Applications

- NASSCO/ICGA Suggested Standard Specification

- CUES Truck and Plant Tours

- Grouting Material Safety

- Packer Operations Using the Control Panel

- Mixing and Customizing Your Grout Mix

- Demos on Mainline, Lateral and Annulus Grouting

- Techniques for Sealing Manholes

Who Should Attend:

Public Works Professionals

Municipal Contractors

City & Consulting Engineers

Regulatory Agencies

Professional Development Hours (PDH) are available for each of these events.

Click here for more information.

Uncategorized

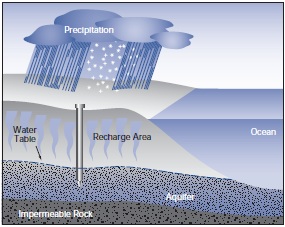

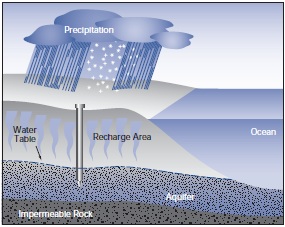

Many green infrastructure practices manage stormwater by allowing it to soak into the ground as it would in a natural setting. This approach has the potential to restore groundwater recharge rates, but also has the potential to introduce pollutants into the subsurface.

The reports and articles linked here on the EPA website examine both the ability of green infrastructure to increase groundwater recharge, and the ability of green infrastructure to treat infiltrated water.

Source: EPA.gov

Uncategorized

Join Perma-Liner Industries March 31 – April 2 in Clearwater, Florida for their Trenchless Open House. This three-day event is jam-packed with demonstrations in live municipal utilities.

Join Perma-Liner Industries March 31 – April 2 in Clearwater, Florida for their Trenchless Open House. This three-day event is jam-packed with demonstrations in live municipal utilities.

Experience one-on-one time with field technicians, sales and marketing team members.

TUESDAY, MARCH 31ST

Demonstration: 9:00am: Perma-Lateral™ Tear-Away with Steam Cure

11:00am: Lunch

12:00pm: Perma-Lateral™ Tear-Away with Steam Cure

1:00pm: Perma-Liner™ Sectional Point Repair

2:00pm: Picote Solutions Demonstration

3:00pm: Dancutter Robotics Demonstration

4:00pm: Schwalm Robotics Demonstration

WEDNESDAY, APRIL 1ST

Demonstration: 9:00am: Perma-Liner™ Sectional Point Repair

11:00am: Lunch

12:00pm: CIP Manhole Rehabilitation

2:00pm: Post Inspection of Perma-Lateral™ Tear-Away

3:00pm: Post Inspection of Perma-Liner™ Sectional Point Repair

4:00pm: Post Inspection of CIP Manhole Rehabilitation

THURSDAY, APRIL 2ND

Demonstration: 9:00am: Perma-Main™ Continuous Lining

Call 1-866-336-2568 for more details.

Uncategorized

Water pollution degrades surface waters making them unsafe for drinking, fishing, swimming,  and other activities. As authorized by the Clean Water Act, the National Pollutant Discharge Elimination System (NPDES) permit program controls water pollution by regulating point sources that discharge pollutants into waters of the United States.

and other activities. As authorized by the Clean Water Act, the National Pollutant Discharge Elimination System (NPDES) permit program controls water pollution by regulating point sources that discharge pollutants into waters of the United States.

Point sources are discrete conveyances such as pipes or man-made ditches. Individual homes that are connected to a municipal system, use a septic system, or do not have a surface discharge do not need an NPDES permit; however, industrial, municipal, and other facilities must obtain permits if their discharges go directly to surface waters. In most cases, the NPDES permit program is administered by authorized states.

Since its introduction in 1972, the NPDES permit program is responsible for significant improvements to our Nation’s water quality.

Learn more about NPDES on the US EPA website.

Source: EPA.gov