Located on a beautiful peninsula between the Gulf of Mexico and Tampa Bay, the City of St.  Petersburg is the fourth largest city in Florida. Home to the Tampa Bay Rays MLB team, Salvador Dali Museum, annual Gran Prix Indy Car race, and the St. Pete Pier, the “Sunshine City” is committed to protecting the unique environment of Tampa Bay. The City pioneered wastewater reuse over 40 years ago with the first reclaim water system in the country. To further this legacy, the City recently embarked on a major wastewater pump station and 30-inch pipeline project that would enable the closure of the Albert Whitted Water Reclamation Facility (AWWRF) and transfer the gravity sewage flow to the Southwest Water Reclamation Facility. The City retained multiple consultants to design and bid the project in five parts, four of which dealt withthe nearly seven mile long force main.

Petersburg is the fourth largest city in Florida. Home to the Tampa Bay Rays MLB team, Salvador Dali Museum, annual Gran Prix Indy Car race, and the St. Pete Pier, the “Sunshine City” is committed to protecting the unique environment of Tampa Bay. The City pioneered wastewater reuse over 40 years ago with the first reclaim water system in the country. To further this legacy, the City recently embarked on a major wastewater pump station and 30-inch pipeline project that would enable the closure of the Albert Whitted Water Reclamation Facility (AWWRF) and transfer the gravity sewage flow to the Southwest Water Reclamation Facility. The City retained multiple consultants to design and bid the project in five parts, four of which dealt withthe nearly seven mile long force main.

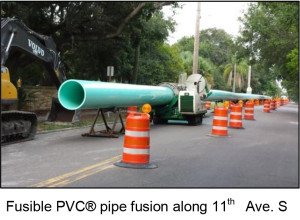

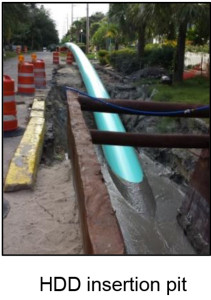

George F. Young, Inc. (GFYI) was retained to design the force main section nearest the AWWRF, known as Part D. The alignment traversed historic neighborhoods on the outskirts of downtown and, in one area, crossed a vital four lane road to downtown and a major drainage structure. As Toby Spurge, GFYI Engineering VP, explained: “After studying various options to cross these key areas, a single horizontal directional drill of approximately 1,700 linear feet was determined to be the best approach. Bidding contractors were given two HDD pipe options that provided equivalent flow area and pressure rating: 30-inch DR21 Fusible PVC® pipe or 36-inch DR9 HDPE.”

Pipeline Details and Project Summary

Project: LS85 Albert Whitted Master 30” Force Main, Part D

Length/Pipe Size: 1,700 LF, 30-inch DR 21 FPVC® pipe

Installation: HDD

Owner: City of St Petersburg

Engineer: George F. Young, Inc.

Contractor/Driller: Dallas 1 Corp. / Gator Boring & Trenching, Inc.

Craig Kubiniec, Dallas 1 Project Manager, noted that: “The HDD was a very challenging aspect of the project due to limited space and the desire to minimize public disruption. Minimizing borehole size with Fusible PVC® pipe was a major benefit as drilling conditions were more difficult than expected. UGSI’s assistance with pipe layout and fusion was outstanding.”

Thank you to Underground Solutions for content and photos.