To keep pace with technology and to ensure that we meet and exceed our client’s expectations of high quality and reliability, Tri-State Utilities introduced a Laser Pipe Profiling System. The KS135 Scan Camera will revolutionize the pipe profiling process by using the “spinning laser” profiling technology. It is a 3 in 1 system where two laser diodes are integrated on either side to the conventional CCTV camera lens to perform three functions:

- Conventional CCTV video pipe inspection

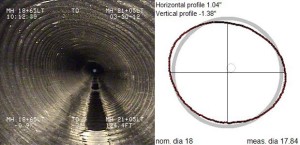

- Laser profiling – precise measurement of diameter, deflection and deformation of pipe

- Crack & Joint measurement

The Rausch Laser Profiler features two laser diodes that are integrated into the KS135 Scan camera head. When these laser diodes project laser dots onto the inner pipe wall, the camera head rotates to measure the diameter and all changes via triangulation calculations. This method is called the “spinning laser” pipe profiling technology. Working in conjunction with the POSM software, the comprehensive scan generates easy to use reports to profile the pipe.

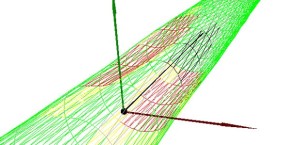

On the way into the pipe, the system is used to perform conventional CCTV video inspection, as well as measuring all joint widths. Laser measurements can be taken at any time to determine the actual pipe diameter and deflection, called a single point scan. On the way out of the pipe, the system performs a “spinning laser” scan of the entire length of the pipe. The camera head swivels perpendicular to the pipe wall and rotates at a defined speed. The Scan software continuously calculates the precise pipe diameter and all deflections and deformations in the pipe profile. One the run is completed, the software instantly generates the graphs in 2- and 3-D. This process may prove invaluable when performing Post Installation Inspection of new pipes. These graphs will show deflectio n, the average pipe diameter, and will also contain an inclinomitor for recording the grade of the pipe.

n, the average pipe diameter, and will also contain an inclinomitor for recording the grade of the pipe.

Learn more on the Tri-State Utilities website.