Uncategorized

Market Segment: Cured-in-place pipe

Composite Application: Culvert rehabilitation

Resin: Vipel® isophthlalic/unsaturated polyester resin

Pipe Diamter: 60 inches (1,500 mm)

Pipe Length: 147 Feet (45 meters)

Installed: 2015

Location: Puebla, Mexico

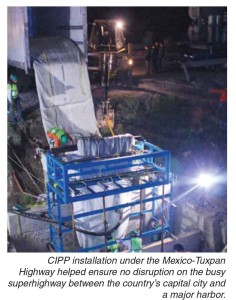

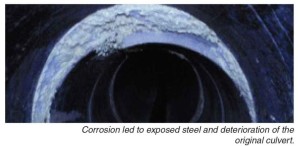

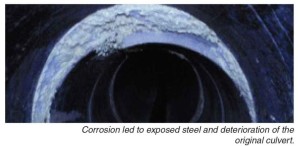

In early 2015, a culvert under the surface of the Mexico-Tuxpan Highway near Puebla, Mexico, was nearing collapse. Corrosion from frequent storms led to exposed steel and falling pieces, which posed a risk to the 10,500 vehicles that travel on the highway daily. The federal

organization that oversees transportation, the Caminos y Puentes Federales de Ingresos Servicios Conexos (CAPUFE), turned to Tubepol for an immediate solution.

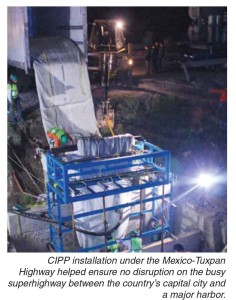

Tubepol, a cured-in-place pipe (CIPP) provider based in Mexico City, designed a trenchless solution using AOC’s Vipel® resin to rehabilitate the pipe. Mexico typically relies on traditional methods, such as open-cut trench excavation. Open-cut pipe replacement wasn’t an option for this project because it would disrupt traffic on the busy 310-kilometer stretch of highway between the capital, Mexico City, and one of the country’s most important harbors, Tuxpan on the Gulf of Mexico.

Cured-in-place pipe rehabilitation was ideal for the Mexico-Tuxpan Highway project. The seamless pipewithin- a-pipe system relied on quality materials, including Vipel® L704-AAP, an isophthalic-based resin that provides the corrosion resistance, durability and toughness required for CIPP applications.

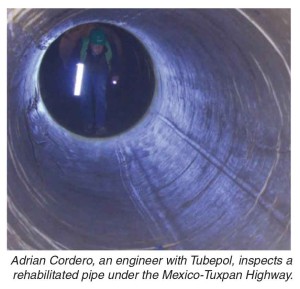

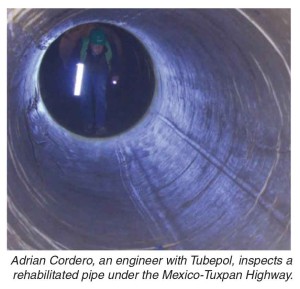

Tubepol and AOC worked hand-in-hand on the CIPP project, the first of its kind in Mexico. “The process was not simple,” says Adrian Cordero, an engineer and head representative of Tubepol. “It took us weeks to plan the perfect and fastest execution without compromising the

security of the highway.”

Designing the CIPP lining presented one of the primary challenges. “We needed a functional tube capable of handling ground loads and settles,” says Engineer Jorge Pérez-Gavilán, Tubepol’s field foreman. The design team opted for a 25 mm liner.

Because of the ground’s pronounced 12.4°slope, Tubepol opted to install the liner cure using compressed air and cure it with steam. Using hot water as the curing mechanism would have been nearly impossible as it would have required a large volume of water, which would have created excessive pressure on the nose of the inverting liner. Steam curing also provided an enormous time advantage: It took only three hours to cure the liner.

Tough conditions prevailed during the installation, including fog, rain and even a flood. But thanks to its excellent wet-out and cure properties, the Vipel® resin behaved as expected. The liner was cured and a temperature of 212° F/100°C resulting in new pipe with improved structural and hydraulic performance.

The success of this project has gained visibility for Tubepol and spread the word throughout Mexico about the benefits of no-dig rehabilitation technologies, such as CIPP.

About Tubepol

Tubepol is a full-service CIPP provider located in Mexico City. It solves customers’ pipeline issues, offering video inspection, pipe fabrication, installation, curing,  and final inspection. Tubepol also provides free educational seminars on CIPP to maintenance chiefs at government organizations and private companies. For more information, contact Rodrigo Zavala, at (+52) 1209-0152 or email ingenieria@tubepol.com.

and final inspection. Tubepol also provides free educational seminars on CIPP to maintenance chiefs at government organizations and private companies. For more information, contact Rodrigo Zavala, at (+52) 1209-0152 or email ingenieria@tubepol.com.

About AOC

AOC is a leading global supplier of resins, gel coats, colorants, dispersions and synergistic material systems for composites and cast polymers. AOC develops technology, lives quality and delivers service better than any other resin supplier. For more information, visit: www.aoc-resins.com.

Uncategorized

Release Date: 05/20/2015

Contact Information: David Sternberg (215) 814-5548 sternberg.david@epa.gov

(PHILADELPHIA- May 20, 2015)– The U.S. Environmental Protection Agency, the District of Columbia (District) and DC Water today announced an agreement to modify a 2005 federal consent decree (CD) allowing DC Water to incorporate green infrastructure in its long-term strategy for curtailing combined sewer overflows (CSOs).

The modification, filed yesterday in Federal District Court in Washington, D.C., gives DC Water the go-ahead to pursue an integrated green/gray infrastructure approach to address water quality issues in the Rock Creek and Potomac watersheds resulting from combined sewer overflows. This integrated approach utilizes green infrastructure in a targeted and sound engineering manner to reduce combined sewer overflows. Green infrastructure uses vegetation, soils, and natural processes that mimic nature, to soak up and store rainwater water where it falls to control wet weather pollution and create healthier urban environments.

“This modification represents significant efforts by all the parties to make green infrastructure an integral part of the solution to curtailing sewer overflows and protecting urban waters,” said EPA Regional Administrator Shawn M. Garvin. “We expect that the green infrastructure components of this modification will provide a model of sustainability for others to follow.”

“This innovative plan will significantly reduce sewer overflows into our rivers and capture rainwater in the area’s ecologically important watersheds,” said Assistant Attorney General John C. Cruden for the Justice Department’s Environment and Natural Resources Division. “This plan puts Washington, D.C. among America’s green city innovators, and it reflects the Justice Department’s and EPA’s commitment to work with cities to safeguard public health, adapt to climate change, and improve aging sewer infrastructure using smart and environmentally sound solutions.”

The green infrastructure projects in Rock Creek and Potomac watersheds are slated to begin in 2015 and 2016 respectively, providing more immediate pollution reductions, enhancements to community livability, and green jobs opportunities.

Specifically the CD modification includes:

· Using green infrastructure to retain the first 1.2 inches of rainwater on 365 acres in the Rock Creek area, and 133 acres in the Potomac watershed.

· Potentially eliminating the Rock Creek storage tunnel and significantly decreasing the size of the Potomac tunnel depending upon the success demonstrated by green infrastructure.

· The District providing the public space necessary for DC Water to construct the proposed green infrastructure projects, and making changes to District regulations, codes, standards, guidelines and policies needed for implementation.

· Requiring the District and DC Water to work together to coordinate capital projects and expenditures for implementing green infrastructure, enabling the efficient use of resources and minimizing costs to rate-payers and taxpayers.

As part of the agreement, DC Water will have an additional five years to complete implementation in the Potomac and Rock Creek watersheds beyond those provided for in the original 2005 consent decree, which established a compliance schedule to construct tunnels in the Anacostia, Potomac and Rock Creek watersheds. The schedule for completing the Anacostia tunnel remains unchanged.

Under this consent decree, DC Water will continue moving forward under this consent decree on the construction of the overall CSO control project which is known as the Clean Rivers Program. This program involves completion of, besides the components described above, control structures and tunnels for the Anacostia watershed, which contributes more than 65 percent of the sewage discharged to District waters annually. Major portions of this tunnel system are scheduled for completed and in operation in 2018. When the Anacostia tunnel complex is fully completed in 2025, it will nearly eliminate combined sewer overflows to the Anacostia in an average rainfall year.

In November 2011, DC Water proposed to EPA to incorporate green infrastructure into its overflow control strategies for the Potomac and Rock Creek watersheds. As part of the request, DC Water submitted analysis demonstrating that modified CSO controls in the Potomac and green infrastructure in Rock Creek could provide equivalent pollution reductions to those in the original plan and were economically feasible.

In early 2014, after conducting a public participation process, DC Water filed a request to EPA to modify the plan for CSO controls and deadlines set forth in the 2005 CD.

During the CD modification discussions, DC Water has continued to move forward in a timely fashion to enhance its nutrient reduction treatment systems at the Blue Plains Advanced Wastewater Treatment Plant. This is an important element of the Bay watershed restoration effort because the Blue Plains facility is the largest point source of nutrient pollution in the Chesapeake Bay drainage area. The proposed CD modification is subject to a 30-day public comment period once it is published for public notice in the Federal Register, and must be approved by the Court. The proposed CD modification will be available at: http://www.justice.gov/enrd/consent-decrees

Uncategorized

CIPP Corporation held its annual meeting in February and presented three very distinctive  awards. Tri-State Utilities was awarded the CIPP Corp. Annual Installers’ Contractor of the Year award for 2014. This marks the 5th consecutive year of being honored with this award and 8th time overall.

awards. Tri-State Utilities was awarded the CIPP Corp. Annual Installers’ Contractor of the Year award for 2014. This marks the 5th consecutive year of being honored with this award and 8th time overall.

Andy McSweeney, Joe McSweeney, and Jonathan Thomas (shown right) were all on hand to accept the award. Over the past 15 years, Tri-State Utilities has installed more than 1,750,000 lf of Cured-In-Place Pipe.

The CIPP Corp. Project of the Year Award went to Mr. Rehab, Inc. of Pennsylvania for their work on Hershey’s Chocolate Plant Pipe Improvements anHoerr Construction of Illinois took home the CIPP Corp. Growth Award for 2014. Congratulations to all!

Visit the Tri-State Utilities’ website for more information on the organization.

Uncategorized

PELLA, Iowa — Vermeer Corporation is pleased to introduce the Ultimate Crew contest semifinalists. Eight crews from across North America are one step closer to winning a trip to the International Construction & Utility Equipment Exposition(ICUEE) 2015 where they will compete for the grand prize package — which includes the use of a Vermeer D24x40 Series II Navigator® horizontal directional drill for 12 months and the chance to be featured in future Vermeer marketing efforts.

Vermeer congratulates the eight semifinalists:

Crew: Chase Boyer, Colby Boyer, John Boyer, Scott Boyer and Steve Boyer

Crew: Mike Millner, Neal Vatnsdal and Jedd Von Ende

Crew: Elena Bisognin, Nathan Shalay, Paul Stancic and Chuck Ulmer

Crew: Ivan Hershberger, Justin Hershberger, Marvin Hershberger, Reuben Hershberger and Raymond Mast

Crew: Tim Beyerink, David Hildreth, Tom Hildreth and Shannon Pierce

Crew: Orin Blackmore, Ron Cole, Rodney Gilliam, Terry Gorsuch and Frazier Yazzie

M3 Contracting, from Monticello, Minnesota

Crew: Colby Mavencamp, Dave Mavencamp, Mike Muir and Matt Schneider

Precision Underground Inc., from Bismarck, North Dakota

Crew: Tyler Blauert, Delbert Maruska and Sara Ryckman

Contest participants were asked to submit essays explaining what made their HDD operator, locator, mud technician and supervisor the Ultimate Crew. The essays were reviewed by a panel of five independent judges — each an industry expert in his or her own right — who narrowed the field to eight semifinalists.

Video interviews with each crew will be posted on NavigatorNation.com on June 1. Industry peers are asked to vote for their favorite crew through August 31, 2015. The four crews with the most votes will be invited to participate in the Underground Showdown HDD skill competition held at ICUEE in Louisville, Kentucky, in October. The crew that performs the most accurate bore on the course carefully designed by Vermeer will be named the Ultimate Crew.

After the Ultimate Crew has been selected at ICUEE, they will be highlighted in Vermeer advertising running in key underground publications. In addition, they will participate in a “Behind the Job”Web series. Each episode will focus on the challenges faced on HDD jobsites, how the crew works together to complete a job, as well as how they are using technology to succeed and stay productive. The Web series will be hosted on NavigatorNation.com and YouTube.

Vote for the Ultimate Crew semifinalists through August 31, 2015 at NavigatorNation.com.

Vermeer, the Vermeer logo, Equipped to Do More and Navigator are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2015 Vermeer Corporation

All Rights Reserved.

Please send all reader inquiries to:

Vermeer Corporation

P.O. Box 200

Pella, Iowa 50219

+1-641-628-3141

Uncategorized

May 8, 2015 – PELLA, Iowa– Ring-O-Matic Inc., an Iowa based manufacturer of vacuum  excavators, is pleased to announce the appointment of Brian Metcalf as CEO.

excavators, is pleased to announce the appointment of Brian Metcalf as CEO.

For the past eight years Metcalf has been president of HammerHead Trenchless Equipment of Lake Mills, Wisconsin, a Charles Machine Works company. A Pella native, Brian has previously held leadership positions at both Vermeer Corporation and Pella Corporation.

“I’m excited to be returning to the Pella area and I am honored to be joining the Ring-O-Matic family,” said Metcalf. “Ring-O-Matic has nearly a 60-year history full of unique innovations to meet the needs of customers. The company is well positioned as a privately held company for an expanded role in providing unique customer-driven solutions in trailer- and truck-mounted utility construction vacuum excavators, industrial vacuum excavators, and car wash pit cleaners.”

Vacuum excavators are powerful suction machines used to remove material and debris from the surface or below it.

As CEO, Metcalf will direct his attention to developing a sustainable strategic growth plan to position Ring-O-Matic as the preferred supplier of vacuum excavators, as well as its complement of related support products to meet customer requirements at jobsites worldwide. He will also determine how additional resources will focus on creating product offerings to achieve operational excellence and expand the market.

“We are enthusiastic to have Brian on board,” said Bob Zylstra, Ring-O-Matic’s owner and chairman. “Brian’s been in the industry for nearly 25 years. He has significant experience in all aspects of our business and industry. We’re fortunate to have his leadership, vision, and experience at Ring-O-Matic as we begin our next chapter.”

Metcalf said, “I’m excited to join Ring-O-Matic and look forward to leading our team in support of its existing loyal customers and in earning the business of new customers worldwide.”

For more information, contact:

Ken Kraus

Ring-O-Matic, Inc.

641-632-7752

Ring-O-Matic, Inc. of Pella, Iowa, USA, manufactures a full line of vacuum excavation machines and car wash pit cleaners. Ring-O-Matic’s product line has a strong reputation for reliability and ease-of-use. Ring-O-Matic offers worldwide sales, support, service and parts through a network of authorized dealers. For more information about Ring-O-Matic products, please call 800-544-2518or visit www.ring-o-matic.com.

and final inspection. Tubepol also provides free educational seminars on CIPP to maintenance chiefs at government organizations and private companies. For more information, contact Rodrigo Zavala, at (+52) 1209-0152 or email ingenieria@tubepol.com.

and final inspection. Tubepol also provides free educational seminars on CIPP to maintenance chiefs at government organizations and private companies. For more information, contact Rodrigo Zavala, at (+52) 1209-0152 or email ingenieria@tubepol.com.