Blog, Industry News

The Call for Papers is now open for the Trenchless World Congress in Medellin, Colombia. Trenchless World Congress 2017 takes place at Plaza Mayor Conference and Exhibition Centre on 25th to 27th September 2017. This event gives attendees an opportunity to see first-hand the latest the industry has to offer and to learn about the application and operations of a wide variety of trenchless products, and services directly from company experts.

The Call for Papers is now open for the Trenchless World Congress in Medellin, Colombia. Trenchless World Congress 2017 takes place at Plaza Mayor Conference and Exhibition Centre on 25th to 27th September 2017. This event gives attendees an opportunity to see first-hand the latest the industry has to offer and to learn about the application and operations of a wide variety of trenchless products, and services directly from company experts.

Abstracts

Abstracts submitted on any topic relevant to Trenchless Technology including new installations, rehabilitation, replacement, inspection, and assessment of all underground utilities.

Abstracts submitted on any topic relevant to Trenchless Technology including new installations, rehabilitation, replacement, inspection, and assessment of all underground utilities.

To ensure publication quality and uniformity, the following requirements have been prepared to assist authors in preparing papers for the Conference.

- A 200 words maximum abstract (in English) outlining the scope of their paper.

- Figures, tables, diagrams and illustrations forming part of your abstract.

- References in alphabetical order.

- The page number should appear centered as a footer.

Conditions:

All abstracts and full papers will be publish for distribution to delegates at the conference and may subsequently be publish separately.

Authors will be required to assign copyright to the ISTT and CISTT.

Deadlines

31 March 2017 – Abstracts deadline

5 May 2017 – Speakers notified

5 May 2017 – Submit draft papers

5 July 2017 – Speakers to submit final papers & speakers must register

Speaker registration is Free ($0usd) for ISTT societies, Universities, Utilities or Research for new Trenchless Technologies.

Speaker registration fee: $650usd commercial conferences

Learn more at nodigcolombia.com!

Blog, Industry News, trenchless products

New sourcehdd.com features cleaner look, enhanced content and intuitive navigation

(Hutchinson, KS) – Source: HDD, Inc. today announced the launch of a new website, www.sourcehdd.com.

(Hutchinson, KS) – Source: HDD, Inc. today announced the launch of a new website, www.sourcehdd.com.

The full-featured website is designed to assist HDD professionals make well-in formed decisions by streamlining the process of locating and researching used horizontal directional drilling rigs and equipment, as well as new down-hole tools and tooling packages from StraightLine HDD.

The site’s refreshed and simplified look also contains a number of enhancements designed to give users a more engaging experience and access to richer content. Robust search functionality makes it easy to locate equipment, over the entire range of product categories.

Created with the user experience in mind, the site has been designed to work efficiently over all modern browsers and is optimized to allow visitors to easily identify products and interact with the site over multiple devises, including mobile.

Users will also find sharing products and pages that interest them easier with enhanced sharing functionality.

Blog, Industry News, trenchless products

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, announces it will be  highlighting its new 350 HS Antenna with HyperStacking™ technology and SIR® 4000 GPR control unit at the American Geophysical Union’s Fall Meeting, which will be held December 12-16, 2016, in San Francisco, CA. GSSI will also showcase research findings made by the winners of the GSSI Student Grant. The yearly grant funded by GSSI includes a cash award of up to $2,000 to student members of AGU’s Near-Surface Geophysics Focus Group, and use of equipment for field geophysical research using GPR and electromagnetic methods.

highlighting its new 350 HS Antenna with HyperStacking™ technology and SIR® 4000 GPR control unit at the American Geophysical Union’s Fall Meeting, which will be held December 12-16, 2016, in San Francisco, CA. GSSI will also showcase research findings made by the winners of the GSSI Student Grant. The yearly grant funded by GSSI includes a cash award of up to $2,000 to student members of AGU’s Near-Surface Geophysics Focus Group, and use of equipment for field geophysical research using GPR and electromagnetic methods.

The new 350 HS Antenna on display greatly improves the depth and data resolution performance of traditional real time sampling technologies. The 350 HS is designed for use with new digital HyperStacking™ technology, which allows users to see deeper targets and operate in conditions considered too “noisy” for conventional systems. Easily configurable, the 350 HS antenna is ideal for archaeology, geophysics, and utility locating applications.

Also to be showcased is the SIR 4000 GPR control unit, which is designed to bridge the legacy of traditional GSSI analog antennas with next-generation of digital offerings. The SIR 4000 GPR control unit supports beginner to advanced users in numerous applications. It offers unique collection modules, including Quick 3D, UtilityScan, StructureScan, and Expert Mode for efficient data collection and visualization. SIR 4000 also incorporates advanced display methods and filtering capabilities for ‘in-the-field’ processing and imaging. Fully integrated, the SIR 4000 provides a 10.4 inch high definition LED display, a simple user interface, and plug-and-play GPS integration.

GSSI will also honor the winners of the annual GSSI Student Grant. Student winners publish findings made with the equipment and present their findings at AGU’s Fall Meeting. “We are so pleased to be able to support student members of AGU’s Near Surface Geophysics Focus Group with opportunities to advance their research and field work,” said Paul Fowler, VP Sales and Marketing. “Offering recognition and financial support is a great way to advance the field and train the next generation of GPR practitioners.”

About GSSI

Geophysical Survey Systems, Inc. is the world leader in the development, manufacture, and sale of ground penetrating radar (GPR) equipment, primarily for the concrete inspection, utility mapping and locating, road and bridge deck evaluation, geophysics, and archaeology markets. Our equipment is used all over the world to explore the subsurface of the earth and to inspect infrastructure systems non-destructively. GSSI created the first commercial GPR system nearly 45 years ago and continues to provide the widest range and highest quality GPR equipment available today.

Blog, Industry News, trenchless products

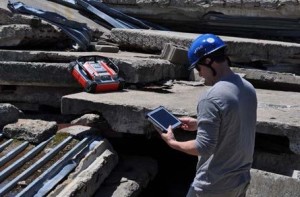

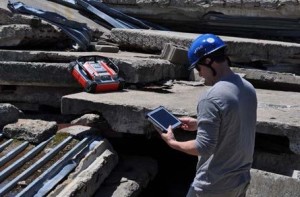

By Tom Timperman, GSSI

Disaster scenes are chaotic and noisy, with rescue teams climbing over collapsed structures, feverishly working to find survivors. Technology can play an important role in the effort, whether the structural collapse is due to earthquake, human-caused disaster, flood or tsunami, mudslide, avalanche, or even urban terrorism. Several options are currently available, but the most effective option is the combination of highly trained search-and-rescue dogs together with ultra-wide band (UWB) radar. Pairing the dog’s dynamic nose with the UWB radar’s ability to see through building materials in determining the approximate distance to the survivor is a huge benefit for urban search-and-rescue (USAR) teams. Already used successfully all over the world, UWB radar would be a great addition to the tools available to rescuers in the United States and Canada, providing current FCC radio emissions regulations can be amended.

Methods used to locate survivors trapped under collapsed debris

Four technologies are typically used by USAR teams to locate survivors of structural collapses at disaster scenes: Rescue dogs, acoustic vibration monitoring devices, borehole cameras, and ultra-wide band (UWB) radar.

Each method has its advantages and disadvantages. Here’s a run-down of the most commonly applied methodologies.

Rescue dogs are indeed amazing. Quick and effective, trained dogs are incredibly dynamic, can cover large areas, and work remotely from their handler. However, dogs cannot determine the distance to a buried survivor, and can be affected by scent drift during windy conditions. Just like humans, they are also prone to fatigue and stress, and require downtime to recuperate. An eye-opening report on the limitations of search-and-rescue dogs came out of the recent large earthquake in Ecuador. The emotional story concerned a beloved and acclaimed dog that found a handful of survivors, only to succumb to heat exhaustion due to over-use.

Acoustic vibration monitoring devices can be placed on top of the rubble pile to listen for sounds from a survivor – tapping, yelling, kicking, or noise of any kind. They require a high level of user expertise, and require almost complete silence. Such silence is very difficult to achieve at these frantic scenes, where military, police, and fire department personnel are present, along with relatives and other rescue groups. The greatest disadvantage to acoustic devices is that they require active participation by a survivor. If the survivor is incapacitated or unconscious, they will unfortunately not be capable of such participation.

A borehole camera is a lightweight, three-in-one device that contains a small camera, flashlight, and microphone. These sophisticated “selfie sticks” provide visual confirmation of the presence of a survivor or victim. They enable two-way communication between rescuers and survivors, but have a limited depth of penetration (3-4 meters) compared to other options. Their primary drawback is that they require direct line-of-sight to the survivor through an opening of some kind in the rubble pile, which is not always available.

Ultra-wide band (UWB) radar offers the most effective and efficient compliment to search dogs by providing  very fine and immediate motion detection. The radar sends out 800,000 pulses per second while measuring the two-way transit time between the unit and the survivor. UWB radar is also extremely safe; the radar energy emitted is equal to one-hundredth of the power emitted by a cell phone.

very fine and immediate motion detection. The radar sends out 800,000 pulses per second while measuring the two-way transit time between the unit and the survivor. UWB radar is also extremely safe; the radar energy emitted is equal to one-hundredth of the power emitted by a cell phone.

Application of such radar driven technology is not new, having been widely used for automotive collision-detection systems, wireless communications, indoor positioning, and sensor networks. It has recently been adapted to USAR scenarios because it provides a wider band of radar detection, yet is less susceptible to interference than narrow band radar, which provides poor down-range resolution and inability to accurately determine the distance to the victim [1].

As mentioned previously, UWB radar offers the most effective complement when combined with the efforts of the rescue dog. In concert with the dog, rescuers can work quickly and effectively across a predetermined grid on top of the rubble pile. The rescue dog may indicate the presence of a survivor, but cannot tell if the survivor is one, eight, or twelve meters away. By applying UWB radar technology, rescuers can now quickly “localize” the approximate distance to the survivor.

Radar is not diverted by scent, does not get fatigued, and does not require silence or line of sight. It is also a good method of determining where not to dig, which is important on a rubble pile.

Also, it detects user respiratory and cardiac motion, so it cannot be used to detect the deceased. UWB radar cannot see through metal, and is susceptible to noise interference from cell towers or radio communication systems.

The LifeLocator® TRx

Headquartered in Nashua, NH, GSSI began developing the first UWB radar technology for search-and rescue use in 2002, in response to post-911 Homeland Security market needs. USAR agencies had been seeking technologies that could be adapted to search-and-rescue applications, and they determined UWB radar technology to be an excellent option. The first generation of the equipment was dubbed LifeLocator® and released in 2005.

Over the next decade, design improvements were made based on operator feedback and advances in radar technology. In 2015, GSSI released the LifeLocator® TRx, which incorporates a variety of improvements specifically designed to meet the challenging field conditions found in structural collapse search operations. The LifeLocator® TRx detects survivor respirations (as few as 3 per minute; as many as 30 per minute) to a maximum distance of 10 meters (33 feet), and survivor motion to a maximum distance of 12 meters (40 feet).

The TRx can be operated by a single person, and is simple-to-use in detecting survivor motion in as little as 10 seconds. It features a ruggedized design with a Wi-Fi antenna mounted inside the carry handles, making it less susceptible to breakage. The addition of a second battery gives the unit a hot swappable battery configuration, which eliminates downtime while changing batteries on the fly.

More importantly, the TRx now includes greatly enhanced noise filtration and noise immunity capability. The laptop user interface features a noise floor indicator to show the operator the strength of nearby noise interference. This is absolutely critical, since the greater the interference, the greater the possibility of the radar producing a ‘false positive’ survivor location.

Previous generations of the LifeLocator® employed a single radar receiver, while the TRx incorporates twin receivers. Twin receivers improve detection in many situations. For example, if the operator places the system over an area that is partially metal and partially another building material, the TRx will still be able to detect the presence of a survivor under the area that is not under metal. Placing the equipment at different angles gives rescuers different ways to work a pile more intelligently and effectively.

LifeLocator® TRx saves lives

The LifeLocator® TRx has been successfully deployed by fire departments and rescue organizations across the globe  in response to major catastrophes. A global French USAR team recorded a save following the 2010 Haiti earthquake, while Chinese rescue teams experienced the same success in Sichuan Province in 2008.

in response to major catastrophes. A global French USAR team recorded a save following the 2010 Haiti earthquake, while Chinese rescue teams experienced the same success in Sichuan Province in 2008.

Unfortunately, the cutting edge technology cannot currently be used in the United States and Canada due to existing Federal Communications Commission equipment standards.

To ensure that local search-and-rescue teams have access to the most advanced and reliable technology on the market, GSSI encourages the FCC to consider waiving these standards for manufacturers of such life-saving devices. Such consideration will allow the dedicated USAR community to provide the most reliable support during the most catastrophic circumstances, enabling them to quickly and reliably locate survivors.

[1] Trapped-Victim Detection in Post-Disaster Scenarios using Ultra-Wideband Radar, by AN Nezirović, 2010, repository.tudelft.nl.

Blog, Industry News, trenchless products

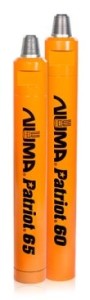

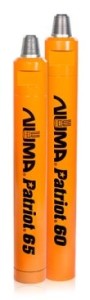

Increased reliability and faster drilling.

THOMPSON, CONNECTICUT USA, November 30, 2016 – Numa, the world’s leader in DTH hammers and bit technology, has released a new generation of Patriot 60 and Patriot 65 hammers. Based upon advanced engineering and driller input, both hammers provide increased reliability, enhanced performance, and faster penetration rates than previous versions.

“The new generation of the Patriot 60 and Patriot 65 hammers was designed with direct feedback from drillers,” said Numa President, Ralph Leonard. “Numa took drillers’ input and created the new generation to deliver fast and reliable drilling in demanding applications around the globe.”

The Patriot 60 hammer is perfectly suited for water well, construction, oil & gas, utility, quarry, and mining drilling applications where contractors are not looking to run a heavy duty version. The hammer features a reversible case and operates at a higher pressure than the previous generation. Tests have proven the hammer has a higher BPM and drills consistently against back pressures, like water in the hole. The Patriot 60 has a 5.5” (139 mm) outside diameter and runs QL60 shank bits capable of drilling holes 6” to 8 ¾ ” (152 to 222 mm) in diameter. A version of the Patriot 60 is also available for 360 shank bits.

The Patriot 65 is a heavy duty hammer designed specifically for the quarry, mining, and construction industries where ground conditions warrant. The hammer boasts a thicker, reversible case but also produces the highest BPM of all Numa hammers. The Patriot 65 comes standard with back out carbides on the topside of the backhead to aid in recovery in the event of hole collapses. An additional option is carbide weld chucks for improved wear in highly abrasive formations. The Patriot 65 has a 5.75” (146 mm) outside diameter and runs QL60 shank bits capable of drilling hole 6 ¼” to 8 ¾” (159 to 222 mm) in diameter.

Numa is featuring the Patriot 60 and Patriot 65 hammers during Groundwater Week, December 7-8 in Las Vegas. Please stop by to discuss the new hammers with our expert staff that will be on hand in booth #1118.

ABOUT NUMA

Numa designs the world’s leading rock drilling technology with over 100 DTH Hammer and Bit products serving 11 different industries. Our products are capable of drilling vertical, horizontal, and reverse circulation holes from 3½ to 48 inches (89 – 1219 mm) in diameter and are used in 105+ countries. We have built our customer-centric reputation on providing the highest value in products, performance, and personal service available in the rock drilling industry.

Blog, Industry News

November 21, 2016

Woodard & Curran (#80 on the Engineering News-Record Top 500 Design Firms list) has acquired RMC Water & Environment (ENR #456), a 125-person, California-based, environmental engineering company focused on developing solutions to the complex challenges of using and protecting water. The acquisition of RMC expands Woodard & Curran’s national footprint to 26 offices in 12 states, and 48 clean water facilities across the country. The combined firm represents 1,000 engineers, scientists, planners, treatment facility operators, and support staff who expect to deliver more than $200 million in projects this year, strengthening its position as one of the top wastewater firms in the country and elevating it into the top 20 for water resources and supply.

“This marks an important milestone in Woodard & Curran’s history,” explained Woodard & Curran CEO, Douglas McKeown. “We have grown steadily since the firm was founded, maintaining our focus on supporting and empowering our people, working side-by-side with our municipal and private sector clients on some of the most important water and environmental challenges. We are thrilled to be able to bring the people of RMC into the Woodard & Curran team, and to be able to leverage their expertise and experience to benefit our employees and clients.”

“We were at a critical point in our growth,” said RMC President Alyson Watson. “Joining forces with Woodard & Curran allows us to expand our capabilities and offer more to our existing clients, and it gives us a national platform to deliver our expertise in water resources to many new clients.”

RMC was founded in the San Francisco Bay Area in 1998. With an impressive portfolio of large-scale projects, industry leadership in water recycling, and a strong reputation, RMC works for some of the largest cities in California on crucial water resource planning. The firm also provides water and wastewater design services to mid-size communities. Recent projects include preliminary design of the Santa Clara Valley Water District’s potable reuse program and design of wastewater treatment plant upgrades for the Cities of Brentwood and Yuba City. Earlier this year, RMC engaged Matheson Financial Advisors to initiate a comprehensive nationwide search for a merger partner that would provide the greatest benefit to both firms. Woodard & Curran was the clear choice, both in terms of service offerings and cultural fit.

Woodard & Curran was founded in Maine in 1979 to help clients address the needs arising out of the Clean Water Act. It has grown steadily since that time with a focus on water and environmental services. Today, the firm works with municipalities, companies, and institutions across a wide range of market sectors to anticipate and solve some of the most important water and environmental challenges in the United States. Recent projects include sewer collection system improvements for the City of Lawrence, MA, design of a wastewater treatment plant for Upper Montgomery Joint Authority in Pennsylvania, and contract operations of the South Sangamon Water District’s water treatment plant in Illinois.

“We have always been a values-driven organization,” said McKeown. “Our mission statement puts our people first, and our growth and success are a direct result of our focus on hiring exceptional people and empowering them to do what they do best. RMC’s history and approach are strikingly similar to our own. The match in values is easily as important as the overlapping set of skills and services across the two firms, and those shared values, expertise, and experience make for a very powerful combination.”

“We made a careful and conscious decision about who to partner with for this process,” added Watson. “Finding a firm that shared our values and had complementary strengths was very important to us. And we found that firm in Woodard & Curran.”

The firms will integrate capabilities beginning immediately, but in the near-term, RMC will retain its focus on serving its clients in California. RMC will operate under a co-branded identity through 2017 and then transition to operating as Woodard & Curran in 2018.

Woodard & Curran has offices in Enfield and Middletown, CT; Duluth, GA; Bangor and Portland, ME; Andover and Dedham, MA; St. Charles, MO; Bozeman, Butte, and Great Falls, MT; Cherry Hill and East Windsor, NJ; Elmira and White Plains, NY; Pittsburgh and Tunkhannock, PA; Providence, RI; and Casper, WY. RMC has offices in Irvine, Los Angeles, Sacramento, San Diego, San Francisco, San Jose, and Walnut Creek, CA.

The Call for Papers is now open for the Trenchless World Congress in Medellin, Colombia. Trenchless World Congress 2017 takes place at Plaza Mayor Conference and Exhibition Centre on 25th to 27th September 2017. This event gives attendees an opportunity to see first-hand the latest the industry has to offer and to learn about the application and operations of a wide variety of trenchless products, and services directly from company experts.

The Call for Papers is now open for the Trenchless World Congress in Medellin, Colombia. Trenchless World Congress 2017 takes place at Plaza Mayor Conference and Exhibition Centre on 25th to 27th September 2017. This event gives attendees an opportunity to see first-hand the latest the industry has to offer and to learn about the application and operations of a wide variety of trenchless products, and services directly from company experts. Abstracts submitted on any topic relevant to Trenchless Technology including new installations, rehabilitation, replacement, inspection, and assessment of all underground utilities.

Abstracts submitted on any topic relevant to Trenchless Technology including new installations, rehabilitation, replacement, inspection, and assessment of all underground utilities.