Blog, Industry News, trenchless projects

Large Diameter XRE Machine to bore Akron, Ohio’s Wastewater Tunnel

A Robbins Crossover (XRE) TBM measuring 9.26 m (30.4 ft) in diameter underwent factory acceptance on May 30, 2016. The gargantuan machine was initially unveiled at Robbins’ Solon, Ohio headquarters during a press day on May 25 before being shipped 40 km (25 mi) south for construction of the Ohio Canal Interceptor Tunnel (OCIT) in Akron. Those present included Akron Mayor Daniel Horrigan, Robbins chief engineer Dennis Ofiara, and David Chastka, project engineer for contractor Kenny-Obayashi JV.

A Robbins Crossover (XRE) TBM measuring 9.26 m (30.4 ft) in diameter underwent factory acceptance on May 30, 2016. The gargantuan machine was initially unveiled at Robbins’ Solon, Ohio headquarters during a press day on May 25 before being shipped 40 km (25 mi) south for construction of the Ohio Canal Interceptor Tunnel (OCIT) in Akron. Those present included Akron Mayor Daniel Horrigan, Robbins chief engineer Dennis Ofiara, and David Chastka, project engineer for contractor Kenny-Obayashi JV.

The TBM, which includes features of both EPB and Hard Rock Single Shield TBM types, is the first Crossover machine to be used in the United States. It will be launched from a 12 m (40 ft) deep portal site and build the first 68 m (226 ft) in soft ground, transitioning to a 183 m (600 ft) long zone of partial face shale before switching to hard-rock mode for the remainder of the drive in full face shale. Probe drilling will be done continuously using two probe drills to determine which mode the TBM should be in.

Unique aspects of the machine include a versatile cutterhead that will be configured with consideration for both the short soft ground section and the longer section (about 65% of the tunnel) in hard rock. A combination of disc cutters and sacrificial rippers will be used in case a cutter becomes blocked. The required rolling torque of the disc cutters has been reduced by 25% to encourage smooth rotation in soft ground. The motors of the XRE machine have been reworked from an original EPB configuration to permit higher motor speed at reduced torque for the open mode segments of the drive.

Muck removal will be achieved with a durable screw conveyor, the first flight of which is covered welded-in wear plates. The auger shaft is lined with hard facing in a crosshatch pattern, while the screw conveyor casing has been similarly lined in wear plates and hard facing. A wear monitoring plan has been prepared for the entire drive in order to maximize efficiency in the section of more abrasive rock. Robbins Project Manager Pablo Salazar is proud of the utilization of local jobs during the TBM construction and design process: “We have built good portion of the machine in the northeast Ohio area. Many components were fabricated locally with sub-suppliers, as well as in our own shop.” The muck will be transported out of the tunnel using a Robbins continuous conveyor system—the setup will be the 100th such conveyor supplied by Robbins for operation behind a TBM.

Muck removal will be achieved with a durable screw conveyor, the first flight of which is covered welded-in wear plates. The auger shaft is lined with hard facing in a crosshatch pattern, while the screw conveyor casing has been similarly lined in wear plates and hard facing. A wear monitoring plan has been prepared for the entire drive in order to maximize efficiency in the section of more abrasive rock. Robbins Project Manager Pablo Salazar is proud of the utilization of local jobs during the TBM construction and design process: “We have built good portion of the machine in the northeast Ohio area. Many components were fabricated locally with sub-suppliers, as well as in our own shop.” The muck will be transported out of the tunnel using a Robbins continuous conveyor system—the setup will be the 100th such conveyor supplied by Robbins for operation behind a TBM.

The machine was dubbed “Rosie” in honor of Rosie the Riveter, an icon representing the American women who worked in factories and shipyards during World War II. Hundreds of “Rosies” including Akron resident Rose May Jacob worked in factories to turn out materials and armaments for the Allied war effort. The TBM will be shipped in truckloads to the jobsite, with the large cutterhead shipped in four pieces. “The entire process of assembly has allowed the contractor to follow very closely through the testing of the machine, so they are very familiar with the TBM at this point. At the jobsite, we will also provide immediate support for both spare parts and personnel,” said Salazar. Jobsite supervisors from Robbins will assist in TBM assembly and excavation for at least the first 1,000 m (3,280 ft) of boring. Tunnel boring is scheduled to begin in August of this year.

The OCIT Project for the City of Akron consists of the construction of a conveyance and storage tunnel system to control Combined Sewer Overflows (CSOs) for several regulators in the downtown Akron area. The EPA-mandated project includes the 1.89 km (1.17 mi) conveyance and storage tunnel, as well as drop shafts, diversion structures, consolidation sewers, and related structures. The consent decree specifies that the tunnel must be operational by December 31, 2018.

The OCIT Project for the City of Akron consists of the construction of a conveyance and storage tunnel system to control Combined Sewer Overflows (CSOs) for several regulators in the downtown Akron area. The EPA-mandated project includes the 1.89 km (1.17 mi) conveyance and storage tunnel, as well as drop shafts, diversion structures, consolidation sewers, and related structures. The consent decree specifies that the tunnel must be operational by December 31, 2018.

Image 1: The 9.26 m (30.4 ft) diameter Robbins Crossover Tunnel Boring Machine (TBM) was designed and built in Robbins’ Solon, Ohio, USA facility.

Image 2: Robbins personnel proudly stand in front of the 9.26 m (30.4 ft) machine dubbed “Rosie”—the first Crossover TBM in the U.S.

Image 3: The Robbins TBM will bore in sections of both hard rock and soft ground to complete the Akron Ohio Canal Interceptor Tunnel (OCIT).

Blog, Industry News, trenchless products

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, announces the launch of the StructureScan™ Pro, a premier concrete scanning system that can accurately inspect concrete, measure slab thickness, and locate voids. StructureScan Pro is the ideal system for locating rebar, post-tension cables, and conduits; conduct real tie surveys for core clearance or post process data for reports. It reaches depths ranging from 0-18 inches. The system includes the newly updated SIR® 4000 control unit and a choice of the popular 1600 MHz or high-resolution 2600 MHz antenna. With a basic antenna upgrade, the SIR-4000 controller can also be used for utility detection and deep void detection applications.

GSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, announces the launch of the StructureScan™ Pro, a premier concrete scanning system that can accurately inspect concrete, measure slab thickness, and locate voids. StructureScan Pro is the ideal system for locating rebar, post-tension cables, and conduits; conduct real tie surveys for core clearance or post process data for reports. It reaches depths ranging from 0-18 inches. The system includes the newly updated SIR® 4000 control unit and a choice of the popular 1600 MHz or high-resolution 2600 MHz antenna. With a basic antenna upgrade, the SIR-4000 controller can also be used for utility detection and deep void detection applications.

StructureScan Pro locates embedments in real-time, showing such information as focus mode, zoom data, depth calibration and target markers. It also allows users to create x-ray-like 3D images of a survey area. The intuitive data visualization features includes the ability to slice through each data layer. Additional features include multiple color themes and save image functionality.

The updated SIR 4000 controller used with the StructureScan Pro is designed to bridge the legacy of GSSI’s traditional analog antennas with next-generation of digital offerings. The updates bring the StructureScan 2D collection module to the controller, simplifying its use for the concrete construction industry. The module includes high frequency antenna-specific set-ups to ensure survey efficiency, and enables the controller to automatically recognize smart antenna set-ups.

The updated SIR 4000 also enables the option of on-the-fly automatic gain to better enhance the data display, while still saving the file in the original raw format for post processing. Fully integrated, the SIR 4000 provides a 10.4 inch high definition LED display, a simple user interface, and plug-and-play GPS integration. The SIR 4000 is designed with a number of exclusive features, including a cast aluminum chassis that offers superior temperature stability, and an impact-resistant design that is fully IP 65 rated and can withstand tough jobsite conditions.

Offering the maximum in mobility, the StructureScan Pro system includes a lightweight, rugged handcart that is simple to transport. Also included is a 7-meter control cable, a rugged carrying case, two batteries and charger.

About GSSI

Geophysical Survey Systems, Inc. is the world leader in the development, manufacture, and sale of ground penetrating radar (GPR) equipment, primarily for the concrete inspection, utility mapping and locating, road and bridge deck evaluation, geophysics, and archaeology markets. Our equipment is used all over the world to explore the subsurface of the earth and to inspect infrastructure systems non-destructively. GSSI created the first commercial GPR system nearly 45 years ago and continues to provide the widest range and highest quality GPR equipment available today.

Blog, Industry News, trenchless products

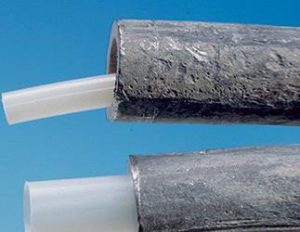

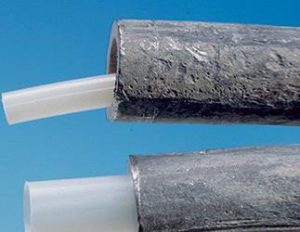

Ottawa, IL, June 20, 2017 – LMK Technologies is proud to announce its continued five year partnership with Flow-Liner as a National Distributor of the Neofit System. The updated Neofit system is a durable, green, and cost effective method of trenchless rehabilitation of potable water lines, providing almost instantaneous results with increased flow rate and minimal diameter loss while creating a barrier from lead, preventing contamination and making water safe for consumers.

Ottawa, IL, June 20, 2017 – LMK Technologies is proud to announce its continued five year partnership with Flow-Liner as a National Distributor of the Neofit System. The updated Neofit system is a durable, green, and cost effective method of trenchless rehabilitation of potable water lines, providing almost instantaneous results with increased flow rate and minimal diameter loss while creating a barrier from lead, preventing contamination and making water safe for consumers.

“LMK is very excited to continue partnership with Flow-Liner,” says Larry Kiest, Jr., President, CTO and Founder of LMK Technologies. “We look forward to promoting this technology with our highly skilled network of licensed contractors and distributors so water utilities across the country can benefit from improved water quality and meet the demand for renewed water service lines, complimenting the rise in rehabilitation of water mains.”

Neofit+ Plus System is a non-invasive pipe lining system especially designed for small diameter potable water service piping. The Neofit+ Plus Liner seals small leaks and pinholes in 1/2″ thru 2″ ID service piping. It also acts as a barrier between existing lead piping and potable drinking water. The Neofit+ Plus Liner is NSF-61 approved and has been tested to a minimum 50+ year life expectancy. LMK is promoting the advanced Neofit processing equipment, now providing lining lengths up to 300 feet. The technique necessitates minimal disturbance of surrounding ground, removing the risk of damaging other utility services. The absence of chemicals required makes it environmentally friendly and allows consumers to receive immediate return to service post processing.

Neofit+ Plus System is a non-invasive pipe lining system especially designed for small diameter potable water service piping. The Neofit+ Plus Liner seals small leaks and pinholes in 1/2″ thru 2″ ID service piping. It also acts as a barrier between existing lead piping and potable drinking water. The Neofit+ Plus Liner is NSF-61 approved and has been tested to a minimum 50+ year life expectancy. LMK is promoting the advanced Neofit processing equipment, now providing lining lengths up to 300 feet. The technique necessitates minimal disturbance of surrounding ground, removing the risk of damaging other utility services. The absence of chemicals required makes it environmentally friendly and allows consumers to receive immediate return to service post processing.

To learn more about the Neofit+ Plus System, please contact LMK at 815-640-9302.

LMK Technologies, a world leader specializing in trenchless methods to renew subterranean pipeline infrastructure, has more than one hundred U.S. and foreign issued patents for its advancements in trenchless technology. Headquartered in Ottawa, IL since 1993, LMK serves the municipal, commercial and residential markets through a network of licensed and certified contractors. For more information regarding LMK, please visit www.lmktechnologies.com, call 1-815-640-9302 or email info@lmktechnologies.com.

Blog, Industry News

The City Director came to Phillip Clark, Water Supervisor for Tavares, FL – America’s Seaplane City, with details of a surplus in the budget. “What can we add to our fleet to work smarter and not harder? What out there in the industry is new and innovative?” He asked.

The City Director came to Phillip Clark, Water Supervisor for Tavares, FL – America’s Seaplane City, with details of a surplus in the budget. “What can we add to our fleet to work smarter and not harder? What out there in the industry is new and innovative?” He asked.

Mr. Clark is constantly researching and reading about what is innovative and groundbreaking. He says that there isn’t much at times to be found, but he saw a VAC-TRON at work on the side of the road and had to look into it. He scheduled a demo and saw how productivity would greatly improve with the use of a low profile, trailered vacuum excavator. So, it was presented to council to be able to add an invaluable machine to their fleet. Council agreed and approved.

Project Descriptions

One of the many tasks his crews must handle is checking meter boxes and cleaning around the roots and debris that collects inside. This routine usually takes an entire day to handle just six or so boxes. Due to the sprawling roots, shovels are used to dig and it has been an inefficient process.

Another task is repairing leaks in water lines and removing the water and dirt to allow for a clear area to work. A sample that Mr. Clark shared was a recent water break under a concrete driveway that had to be broken away to reveal the repair project. It was a 2-inch water break 3 feet under driveway 2 ft. of concrete.

As for all cities – locating underground utilities is a constant project where in the past typically a probe is used. Finding these lines with a probe can be dangerous and time consuming.

Challenges

-Up to a day to clean out and view a half a dozen meter boxes

-Exposure to bugs, snakes, and other elements

-Excavation for small leaks, remove water to find the source of the leak

-Safety when digging around gas and power lines

The Solution

To upgrade from traditional methods of digging to a VAC-TRON increased efficiency. Adding a trailered vacuum excavator by VAC-TRON proved to be a well-made investment. The Low Profile Series has full potholing or daylighting and clean up capabilities with a 300-gallon debris capacity, manual spin-wheel door and two (2) 50-gallon water tanks.

Results

Results

-Easily remove water and dirt for a more productive way to repair water line breaks

-Works as a mobile pressure cleaner as well without having to have a power source

-Will equate in to quick payback for the city, per Mr. Clark

-Keeps the team away from reptiles and insects

-A much safer way to dig

-Using a VAC-TRON only took 30 minutes to clean the same 6 boxes that used to take all day

Blog, Industry News, trenchless products

Truck vacs offer power, scalable tank capacity and reliability for high-production contractors

Truck vacs offer power, scalable tank capacity and reliability for high-production contractors

GREENVILLE, S.C. — June 7, 2017 — McLaughlin has extended its Vermeer MEGA VAC vacuum excavator product line with new PTO-driven options. The Vermeer VXT truck series was developed in response to industry requests for a productive vacuum excavator that meets weight regulations and that is backed by the support of the Vermeer dealer network.

Ideal for utility and distribution contractors, the VXT Series is a reliable, cost-effective solution for high-production potholing crews. The new MEGA VAC PTO-driven vacuum excavators come in three standard spoil capacity options: the VXT6 (6-yard), the VXT8 (8-yard), and the VXT10 (10-yard).

“The new VXT truck series is designed for the production-minded utility contractor who is focused on maximizing uptime and maintaining a safe and productive jobsite,” said Jeff Wage, vice president at McLaughlin. “These machines fit that niche of being able to do the work that’s required at a price point high-production contractors can justify.”

“The new VXT truck series is designed for the production-minded utility contractor who is focused on maximizing uptime and maintaining a safe and productive jobsite,” said Jeff Wage, vice president at McLaughlin. “These machines fit that niche of being able to do the work that’s required at a price point high-production contractors can justify.”

Proven for potholing

The VXT series is a 6-inch (15.2 cm) system featuring spoil tank capacities ranging from 1,200 to 2,000 gallons (4542.5 to 7570.8 L) and a standard option of 800 gallons (3028.3 L) of fresh water. For off-road applications, larger spoil tank capacities are available from 2,200, 2,600 and 3,000 gallons (8327.9, 9842.1 and 11,356.2 L).

“Contractors asked for a 6-inch vacuum excavator for potholing performance and the ability to work in certain rocky and granular ground conditions,” said Wage.

The VXT Series is powered by the industry-proven OMSI Gearbox and a ROOTS 3200 CFM (91 m3/min) blower. When the truck is put into PTO mode, the rear axle is disengaged and the OMSI gearbox becomes live to drive the ROOTS blower at 18 inches of mercury and 3200 cfm. The OMSI gearbox hydraulically provides the power to drive the 10 gpm/3,000 psi water pump as well.

The VXT Series is powered by the industry-proven OMSI Gearbox and a ROOTS 3200 CFM (91 m3/min) blower. When the truck is put into PTO mode, the rear axle is disengaged and the OMSI gearbox becomes live to drive the ROOTS blower at 18 inches of mercury and 3200 cfm. The OMSI gearbox hydraulically provides the power to drive the 10 gpm/3,000 psi water pump as well.

The new CAN Control system allows for two-way communication between the remote control and the vacuum excavator. With the CAN Control system operators can start the MEGA VAC, control the idle speed, dump spoils, open the rear door and control full boom operation, which helps contractors increase jobsite productivity. The controls also give a full readout on performance of the engine, the blower and the water pump.

The new Vacuum Neutral feature adds to operator safety and productivity on the jobsite. In Vacuum Neutral mode, the blower breathes free air and stops suction without the need to close the hydraulic gate valve in the boom. This allows an operator to work safely near the boom without having to shut the vacuum off.

Capacity that will scale

Utility contractors, gas distribution contractors and the large contractors building fiber optic networks must balance the need for maximum spoil tank capacity with increasingly stringent weight regulations and restrictions. The VXT6 and the VXT8 MEGA VACs were designed with scalability as a top priority. Built on a 10-wheel Peterbilt chassis, the VXT6 has a 1,200-gallon (4542.4 L) spoil tank capacity and can carry up to 410 gallons (1552 L) of water and still meet weight regulations. The VXT8 has a 1,600-gallon (6056.7 L) tank capacity and can carry up to 800 gallons (3028.3 L) of fresh water. With a standard drop axle, the VXT8 weighs only 33,000 pounds (14,968.5 kg) empty on the Peterbilt 348 chassis.

“Time and time again, we hear concerns from contractors regarding overweight vehicles on the highway. Allowing units to run overweight puts both their employees and their company at risk for financial and legal repercussions,” said Wage. “By selecting the VXT6 or the VXT8, a contractor can reduce the risks and improve working conditions for their employees.”

For reassurance that the vacuum meets weight regulations, the VXT Series features the new optional Air-Weigh scale system. Incorporated into the chassis and the CAN Controls, the Air-Weigh scale system informs the operator when a truck hits its preprogrammed maximum axle weights. At the point that the truck reaches a preprogramed axle capacity, the unit will automatically enter Vacuum Neutral mode. The control panel message will allow the operator to “override” the Vacuum Neutral mode or can be programed with a security code so only a manager may authorize a system override.

All McLaughlin vacuum excavators are backed by the Vermeer dealer network. The worldwide dealer network means consistent parts availability and a knowledgeable staff wherever the job takes contractors. To learn more, visit mclaughlinunderground.com or email McLaughlin at mmole@mightymole.com.

Blog, Industry News, trenchless projects

Ceremony with Georgian Prime Minister commissions Green Power Station

In April 2017, a ceremony was held to celebrate the commissioning of the Dariali Hydropower Project in the Republic of Georgia. Many attended the ceremony marking the first carbon-neutral hydropower project in the world, including Georgian Prime Minister, Giorgi Kvirikashvili. The power station, an independent power project (IPP) developed through Dariali Energy Ltd, was a joint venture involving three other firms: Georgian private companies Peri Ltd and Energy LLC, and state-owned Georgian Energy Development Fund (GEDF). The Dariali HPP gathers water from the Tergi River and directs it through the headrace tunnel to the power house located near the Russian—Georgian border. Each year, the site will generate 500 GWhs of carbon-neutral energy, with 70 percent of power production occurring during the country’s summer months.

In April 2017, a ceremony was held to celebrate the commissioning of the Dariali Hydropower Project in the Republic of Georgia. Many attended the ceremony marking the first carbon-neutral hydropower project in the world, including Georgian Prime Minister, Giorgi Kvirikashvili. The power station, an independent power project (IPP) developed through Dariali Energy Ltd, was a joint venture involving three other firms: Georgian private companies Peri Ltd and Energy LLC, and state-owned Georgian Energy Development Fund (GEDF). The Dariali HPP gathers water from the Tergi River and directs it through the headrace tunnel to the power house located near the Russian—Georgian border. Each year, the site will generate 500 GWhs of carbon-neutral energy, with 70 percent of power production occurring during the country’s summer months.

Robbins also invested in the project by gaining equity through supplying tunneling equipment and services in consortium with contractor Peri. “Robbins understood the risk in the tunneling portion of the project and we were compensated for taking on part of the risk. Peri is a long-time customer, as we supplied a TBM to them 15 years ago for a small project in Georgia. It was great to be invited to invest and risk share on this project, and to work together again,” said Robbins President Lok Home. The 5 km (3 mi) long headrace tunnel for the power station was bored with the use of a 5.5 m (18 ft) diameter Robbins Main Beam TBM starting in February 2012.

Due to the remote and mountainous location of the jobsite 160 km (100 mi) from the capital Tbilisi, the machine was shipped in pieces to contractor Peri’s workshop, where they were refurbished under Robbins supervision and then delivered to the site to be assembled. Each piece was transported by truck down narrow, winding roads that eventually gave way to dirt paths. Assembly at the jobsite was difficult, as the project site at a 1,700 m (1.0 mi) altitude was blanketed in snow and components arrived in December. Bone-chilling temperatures often reached negative 15 degrees Celsius (5ºF), and 40 below with the wind chill factor. Once the machine had launched, it encountered difficult ground including slate, sandstone, limestone and malms with fault zones.

Due to the remote and mountainous location of the jobsite 160 km (100 mi) from the capital Tbilisi, the machine was shipped in pieces to contractor Peri’s workshop, where they were refurbished under Robbins supervision and then delivered to the site to be assembled. Each piece was transported by truck down narrow, winding roads that eventually gave way to dirt paths. Assembly at the jobsite was difficult, as the project site at a 1,700 m (1.0 mi) altitude was blanketed in snow and components arrived in December. Bone-chilling temperatures often reached negative 15 degrees Celsius (5ºF), and 40 below with the wind chill factor. Once the machine had launched, it encountered difficult ground including slate, sandstone, limestone and malms with fault zones.

“The main challenges we faced were boring the tunnel at a 6 percent incline and having restricted access to service the machine. There were also two major landslides that delayed the project for over a year,” said Home. After the first landslide, the access tunnel, which had allowed mud and water to enter the power station, had to be relocated at a higher elevation and facing away from the river valley. When the machine was nearing the end of its bore, a second landslide blocked the exit portal for the machine as well as access to the main highway. Despite these challenges, tunneling crews persevered and the machine successfully holed through in October 2014.

Throughout the construction process, careful steps were taken to minimize the carbon footprint. Although the plant’s energy production is carbon emission free, construction of the plant was not. To offset these emissions, 7,000 seedlings are being planted all around the area in a reforestation effort. In years to come, the trees will absorb enough carbon dioxide to compensate for the emissions produced during the construction of the hydropower plant.

Overall, said Home, there is much to celebrate as the project has immense benefits: “Not only does it provide affordable electrical power for the country with essentially no pollution effects, but it also provided jobs during construction and will continue providing jobs during its operation and maintenance.”

Overall, said Home, there is much to celebrate as the project has immense benefits: “Not only does it provide affordable electrical power for the country with essentially no pollution effects, but it also provided jobs during construction and will continue providing jobs during its operation and maintenance.”

Image 1: Georgian Prime Minister Giorgi Kvirikashvili marked the startup of the world’s first carbon-neutral hydropower project.

Image 2: In April 2017, the Dariali HPP became operational in the Republic of Georgia.

Image 3: Robbins supplied a 5.5 m (18 ft) diameter Main Beam TBM to bore the 5 km (3 mi) headrace tunnel.

A Robbins Crossover (XRE) TBM measuring 9.26 m (30.4 ft) in diameter underwent factory acceptance on May 30, 2016. The gargantuan machine was initially unveiled at Robbins’ Solon, Ohio headquarters during a press day on May 25 before being shipped 40 km (25 mi) south for construction of the Ohio Canal Interceptor Tunnel (OCIT) in Akron. Those present included Akron Mayor Daniel Horrigan, Robbins chief engineer Dennis Ofiara, and David Chastka, project engineer for contractor Kenny-Obayashi JV.

A Robbins Crossover (XRE) TBM measuring 9.26 m (30.4 ft) in diameter underwent factory acceptance on May 30, 2016. The gargantuan machine was initially unveiled at Robbins’ Solon, Ohio headquarters during a press day on May 25 before being shipped 40 km (25 mi) south for construction of the Ohio Canal Interceptor Tunnel (OCIT) in Akron. Those present included Akron Mayor Daniel Horrigan, Robbins chief engineer Dennis Ofiara, and David Chastka, project engineer for contractor Kenny-Obayashi JV. Muck removal will be achieved with a durable screw conveyor, the first flight of which is covered welded-in wear plates. The auger shaft is lined with hard facing in a crosshatch pattern, while the screw conveyor casing has been similarly lined in wear plates and hard facing. A wear monitoring plan has been prepared for the entire drive in order to maximize efficiency in the section of more abrasive rock. Robbins Project Manager Pablo Salazar is proud of the utilization of local jobs during the TBM construction and design process: “We have built good portion of the machine in the northeast Ohio area. Many components were fabricated locally with sub-suppliers, as well as in our own shop.” The muck will be transported out of the tunnel using a Robbins continuous conveyor system—the setup will be the 100th such conveyor supplied by Robbins for operation behind a TBM.

Muck removal will be achieved with a durable screw conveyor, the first flight of which is covered welded-in wear plates. The auger shaft is lined with hard facing in a crosshatch pattern, while the screw conveyor casing has been similarly lined in wear plates and hard facing. A wear monitoring plan has been prepared for the entire drive in order to maximize efficiency in the section of more abrasive rock. Robbins Project Manager Pablo Salazar is proud of the utilization of local jobs during the TBM construction and design process: “We have built good portion of the machine in the northeast Ohio area. Many components were fabricated locally with sub-suppliers, as well as in our own shop.” The muck will be transported out of the tunnel using a Robbins continuous conveyor system—the setup will be the 100th such conveyor supplied by Robbins for operation behind a TBM. The OCIT Project for the City of Akron consists of the construction of a conveyance and storage tunnel system to control Combined Sewer Overflows (CSOs) for several regulators in the downtown Akron area. The EPA-mandated project includes the 1.89 km (1.17 mi) conveyance and storage tunnel, as well as drop shafts, diversion structures, consolidation sewers, and related structures. The consent decree specifies that the tunnel must be operational by December 31, 2018.

The OCIT Project for the City of Akron consists of the construction of a conveyance and storage tunnel system to control Combined Sewer Overflows (CSOs) for several regulators in the downtown Akron area. The EPA-mandated project includes the 1.89 km (1.17 mi) conveyance and storage tunnel, as well as drop shafts, diversion structures, consolidation sewers, and related structures. The consent decree specifies that the tunnel must be operational by December 31, 2018.