Industry News, trenchless products

Project Profile:

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

During design the team discovered an old as-built drawing of a now abandoned 12″ diameter concrete pipe in the path of the tunnel at approximately 320LF out. A series of GBM pilot tubes were installed ahead of the 51″ diameter tunnel launch in an attempt to proof the drive and find this pipe. Two of the

four pilot tube drives were deflected in this area; indicating that something was out there. After lots of internal discussions the decision was made to carry on with the original design and attempt to tunnel through this questionable area at 320LF out. While carefully tunneling through this area, a large pocket of river rock was discovered, but no remnants of any concrete pipe were ever found. This was great news for the project team. The end result was a successfully installed 51″ casing under I-215 for Salt Lake City Public Utilities, allowing Whitaker Construction to continue on with their project as planned.

Photos: Morty the Tunnel Rat and two members of the BTrenchless Crew getting ready for an Akkerman MTBM launch.

Industry News, trenchless people, trenchless products

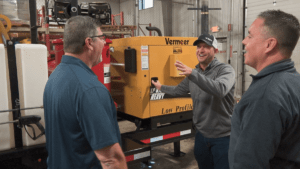

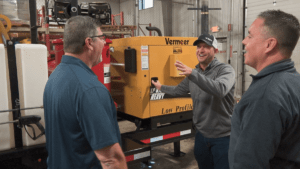

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the Vermeer Vac-Tron Series trailer vacs.

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the Vermeer Vac-Tron Series trailer vacs.

Project Challenge

The team at MacAllister Rental wanted to offer customers with an effective soft excavation method that would deliver outstanding productivity safely. They were familiar with vacuum excavators but wanted to find an equipment partner that manufactured quality machines that were easy to operate and efficient to run.

Solution

MacAllister Rental added Vac-Tron vacs to its fleet eight years ago. Since then, rental demand for these machines has increased significantly, and the rental store has continued to grow its fleet of Vac-Tron vacs. “We feel that CAT is the leader in the hydraulic excavator industry and the Vac-Tron series trailer vac is an industry leader in the vacuum excavator industry, so it fits very well with what we are trying to accomplish,” said Dan Hickman, district sales manager.

According to Chad Brogan, a sales representative with MacAllister Rental, most of their customers use Vac-Tron vacs for precise excavation when conventional excavation is not able to be used. “We have also found other uses for the Vac-Tron vacs with construction and foundation cleanup after heavy rains. It was a no brainer to add it to our fleet because we want to provide the best solutions for our customers,” he added.

Results

“Customers have commented that when they have these on their jobsites, they really have a vacuum, pressure washer, and an air compressor all built into one piece of equipment,” explained Hickman. “I can’t say it enough; contractors can be much more efficient using Vac-Tron vacs than other excavation methods when working around fiber optics, gas or water lines, as well as near foundations and wells. All that material gets sucked up into a self-contained unit, and they can dispose of it where they want to. Our customers get a cleaner jobsite, the job gets done faster with a lot fewer people, so it makes them money,” he concluded.

Learn more about Vac-Tron by visiting vactron.com.

Industry News, trenchless products

KOBUS SERVICES are delighted to announce that the business has won the Abbott Award for Innovative Products & Services for their KPP400 series Pipe Puller at the recent NASTT No-Dig Show in Chicago.

KOBUS SERVICES are delighted to announce that the business has won the Abbott Award for Innovative Products & Services for their KPP400 series Pipe Puller at the recent NASTT No-Dig Show in Chicago.

The award, bestowed by a specially selected judging panel, was given during the show in appreciation of the truly ground-breaking and innovative nature of the product.

The Kobus Pipe Puller KPP400 series has been recognized as the next generation in efficient and effective trenchless rehabilitation pipe repair and replacement technology.

The award recognizes the effort and investment that has been placed into the development of a system designed to help significantly impact the global problem of old service pipes falling into disrepair, leaking, reaching end of life or creating water quality issues.

Kobus Pipe Puller enables the trenchless replacement of gas and water service pipes connecting mains to properties the world over. Now in use in UK, North America, and Australasia, the benefits of the system include less disruption before, during and after works, lower reinstatement costs, higher productivity and overall reduced cost.

Kobus Pipe Puller enables the trenchless replacement of gas and water service pipes connecting mains to properties the world over. Now in use in UK, North America, and Australasia, the benefits of the system include less disruption before, during and after works, lower reinstatement costs, higher productivity and overall reduced cost.

There are also compelling ecological and environmental benefits in completely removing the old pipes from the ground, something other techniques cannot guarantee, eliminating the potential environmental damage leaving it in situ may cause.

Tom Atienza and Simon Drain gratefully received the Award during the show and were mentioned during a presentation at the Gala Dinner.

“The Award was a big surprise as this was our first time visiting and exhibiting at the No Dig Show. NASTT have been enthusiastic supporters of Kobus Pipe Puller and we’ve been working hard to build a North America customer base, which obviously has huge potential and has been very welcoming” said Tom Atienza, operations director.

“We’re grateful to NASTT, sponsors and Benjamin Media for a well-organized No-Dig Show, and congratulations to the other entrants in the Innovative Products Award category”.

Visit kobuspipepuller.com to learn more how Kobus Pipe Puller 300 series (free standing) and 400 series (excavator mounted) can significantly enhance your pipe removal operation.

Industry News, trenchless products

May 1, 2019: Pipe Lining Supply announces its 15th anniversary as a nationwide, full‐service,

May 1, 2019: Pipe Lining Supply announces its 15th anniversary as a nationwide, full‐service,

Pipe Rehabilitation Distributor.

Pipe Lining Supply (PLS) was founded on January 1, 2004 by Linda Heisler. Her primary focus was the CIPP industry in the California area. She saw a need to service customers with reasonably priced materials and great customer service. Two years later her husband John Heisler joined the company bringing a wealth of expansive knowledge of the industry including CIPP Lateral Lining, Pipe Bursting, HDD, Pipe Coating, Sewage Lining, Open Cut and Cover,

Water and Sewer Utility work.

Since 2004 Pipe Lining Supply, has evolved to a reputable company that manufactures and

distributes CIPP lateral lining equipment such as the Quik‐Shot™ System (launched in 2009),

resin and lining materials. In 2017, PLS introduced its AIPPR Quik‐Coating System designed for

drain, waste and vent (DWV) piping extending pipe life by 50+ years. PLS offers a full line of

equipment, materials and expert training to plumbers and drain cleaners so they have a “one

stop shop” in the pipe rehabilitation industry.

The company has also expanded its market, their team includes technical experts across the

USA, but also have a presence nationwide. “Pipe Lining Supply has experienced exceptional

growth and development over the past years” said Heisler. “Moving forward, our focus will

remain the same as day one, offering great equipment and materials with top notch training

and superior customer support.”

Over the past 15 years, Pipe Lining Supply has been evolving into a successful business that is a

leader in the industry with an enthusiasm to keep it growing and changing in the most

competitive way possible.

For more information on Pipe Lining Supply and their products please visit

http://www.pipeliningsupply.com

Contact info: Michelle Strasburg

Director of Marketing

info@pipeliningsupply.com

Phone: +1‐888‐354‐6464

Industry News, trenchless products

PELLA, Iowa, April 11, 2019 – The right-sized mixing system is key for drilling operations. With a redesigned, slim rectangular profile tank, the new Vermeer MX300 mixing system helps horizontal directional drilling (HDD) contractors optimize productivity and offers customizable mounting configuration options. Equipped with a 23 hp (17.2 kW) Kohler ECH 7300 EFI gas engine that outputs 350 gpm (1,324.9 Lpm) of flow, the MX300 mixing system power unit can be paired with up to two tanks at once to help decrease time spent mixing and refilling drilling fluid tanks. The unit’s narrow rectangular tank design also helps maximize fluid volume, and a small footprint can help with convenient transporting and storage.

“The Vermeer MX300 mixing system is an upgrade to the MX240 model,” explained Tod Michael, product manager of trenchless products at Vermeer. “With the ability to use one pump with one or two tanks, the MX300 is scalable to a contractor’s jobsite needs from small bores to large-diameter and longer-distance HDD applications in varying soil types.”

The new Vermeer mixing system can be paired with a 750 gallon (2,839.1 L) or 1,000 gallon (3,785.4 L) tank and works with a variety of horizontal directional drills. It features a wide-mouth hopper and suction hose for the convenient pouring of drilling additives. The tapered bottom of the rectangular tank design helps prevent additives from settling, building up and assists with efficient drainage. At a width of just 40 inches (101.6 centimeters), the MX300 can be mounted to transport two tanks inside a standard-sized enclosed truck.

The MX300 comes with a 16 gallon (60.6 L) fuel tank and is convenient to service with access to the roll jets through the top of the tank and two drainage points that are operated by two accessible valves.

For more information about the Vermeer MX300 mixing system, visit Vermeer.com or contact your local Vermeer dealer.

About Vermeer Corporation

Vermeer delivers a real impact in a progressing world through the manufacture of high-quality underground construction, surface mining, tree care, agriculture and environmental equipment. With a reputation for durability and reliability, that equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer, products, the dealer network and financing options, visit Vermeer.com.

Vermeer Corporation reserves the right to make changes in engineering, design specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Industry News, trenchless products

The team at Kobus Services Ltd, the UK based creators of the innovative Kobus Pipe Puller trenchless utility pipe repair and replacement system, has launched the new KPP400 excavator mounted pipe puller.

The team at Kobus Services Ltd, the UK based creators of the innovative Kobus Pipe Puller trenchless utility pipe repair and replacement system, has launched the new KPP400 excavator mounted pipe puller.

Pipe pulling removes the old pipework from the ground thereby eliminating the potential environmental pollution, as well as enabling the recycling and scrap value recovery of the old pipe.

The 400 Series Pipe Puller delivers a state-of-the-art solution for quickly and effectively removing and replacing service pipes.

The system requires two excavation holes, no larger than 3’ x 3’ depending on depth of service, to extract an old pipe while towing in the new replacement. Up to 85 feet of steel, copper, lead or plastic pipe can be easily replaced in a single pull (for diameters up to 1¼ in), and a new copper or PE pipe drawn in at the same time.

The 400 Series Pipe Puller is mounted on a compact excavator such as 35 or 45 series, and operates from the auxiliary hydraulics. It provides greater pulling power and efficiency improvements for contractors. The unique spool design makes removal of the pipe from the spool after extraction quicker and easier, while the rotatable foot means the puller can be positioned in any direction to suit excavator access.

The 400 Series Pipe Puller is mounted on a compact excavator such as 35 or 45 series, and operates from the auxiliary hydraulics. It provides greater pulling power and efficiency improvements for contractors. The unique spool design makes removal of the pipe from the spool after extraction quicker and easier, while the rotatable foot means the puller can be positioned in any direction to suit excavator access.

The 400 Series Pipe Puller, already in use in five states in the Mid-West and being displayed for the first time at the No Dig Show in Chicago in 17-21 March 2019, can replace all types of service pipes, and combinations of pipe materials with fittings, much faster than more traditional methods. It is ideal for cross road applications and replacement programmes.

With several new features and capabilities, it has been designed in partnership with some of the UK’s leading utility companies, and will bring economic, logistical and business transforming benefits to contractors using it.

With several new features and capabilities, it has been designed in partnership with some of the UK’s leading utility companies, and will bring economic, logistical and business transforming benefits to contractors using it.

“In the United States, the problem is acute. It is estimated there are around 7 million lead pipes, totalling 65,000 miles of lead” says Simon Drain, Kobus Services managing director.

“In the US alone, with just one foot of lead pipe weighing 11 lbs and for an average 50 feet in length, this equates to an astronomical 3.8 billion lbs of lead. Aside the logistical and restoration benefits pipe pulling provides, the average scrap value of lead is approx. US$ 0.75 per lbs. Therefore, the potential scrap value of lead pipe to US contractors alone is worth $2.5 – 3bn”.

Visit https://us.kobuspipepuller.com/ to find out more or http://nodigshow.com/ to book to attend the show in Chicago and meet the Kobus team at booth 246.

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the