Industry News, trenchless projects

Trenchless Technology Center at Louisiana Tech University Awarded Project to Measure Styrene and Other Compounds to Capture Variation in Emissions During Pipe Rehabilitation Using the Cured‐In‐Place Pipe (CIPP) Method

Trenchless Technology Center at Louisiana Tech University Awarded Project to Measure Styrene and Other Compounds to Capture Variation in Emissions During Pipe Rehabilitation Using the Cured‐In‐Place Pipe (CIPP) Method

(Marriottsville, Maryland, June 15, 2018) – After a careful and thorough review of multiple responses to a request for proposal to provide a comprehensive evaluation of air emissions from steam-cured cured-in-place pipe (CIPP) installations and potential impacts on workers and the surrounding community, NASSCO today announces their award of the research project to the Trenchless Technology Center (TTC) at Louisiana Tech University.

The project is Phase 2 of a larger study and calls for measurement of styrene and other organic compounds at six CIPP installation sites, representing different pipe diameters (8”, 12”, and larger), and lengths, in order to capture variation in emissions. Measurements will be conducted before, during, and after curing at the termination manhole, as well as various locations in the surrounding outside area and inside nearby buildings. Worker exposure will also be measured via personal exposure monitors. Finally, dispersion modeling will be conducted to estimate compound concentrations at a large number of locations for a wide variety of meteorological conditions. Measured and modeled concentrations will be compared to appropriate health-based action levels to determine if any potential health risks exist for workers or citizens in the surrounding communities.

The project is Phase 2 of a larger study and calls for measurement of styrene and other organic compounds at six CIPP installation sites, representing different pipe diameters (8”, 12”, and larger), and lengths, in order to capture variation in emissions. Measurements will be conducted before, during, and after curing at the termination manhole, as well as various locations in the surrounding outside area and inside nearby buildings. Worker exposure will also be measured via personal exposure monitors. Finally, dispersion modeling will be conducted to estimate compound concentrations at a large number of locations for a wide variety of meteorological conditions. Measured and modeled concentrations will be compared to appropriate health-based action levels to determine if any potential health risks exist for workers or citizens in the surrounding communities.

Phase 1 was a four-month study on the review of published literature pertaining to chemical emissions during CIPP installations using styrene-based resins. The study, completed on April 6, 2018 by researchers at the University of Texas at Arlington (UTA)’s Center for Underground Infrastructure Research and Education (CUIRE), and the Institute for Underground Infrastructure (IKT) in Germany, found that existing studies do not adequately capture worker exposures or levels in the surrounding areas to which workers or citizens may be exposed. The team further determined that spatial variation of concentrations, and variations in concentrations with different meteorological conditions, are not well determined.

Late last year NASSCO formed a workgroup consisting of industry leaders to develop the requests for proposal for both Phase 1 and 2 and to select from the multiple responses to ensure the highest levels of integrity in the final selections. “As the NASTT representative on the workgroup for the CIPP Emission Testing project, I am delighted with the selection of TTC as the most meritorious candidate for this important research,” said Mike Wilmets, NASTT Executive Director. “For nearly 30 years, TTC has contributed novel and significant work to further the advancement of the trenchless industry. This will be an exciting assignment with definitive results and will undoubtedly have a far-reaching impact on worksite safety.”

As NASSCO’s new Executive Director, Sheila Joy shares the critical need to partner with other industry organizations for important initiative such as this. “One of my top priorities is to join forces with associations and organizations such as NASTT, WRc, WEF, NUCA and others so that we may have a unified voice and serve our industry to the best of our ability. We all share the same goal when it comes to the safety of our workers and communities, and this study is a perfect example of how unification will reveal the information we need to make smarter decisions for our industry as a whole.”

For questions or additional information, please contact NASSCO at 410-442-7473 or visit nassco.org.

Industry News, trenchless people, trenchless projects

Robbins XRE completes the First TBM-driven Tunnel in Albania

On May 3, 2018 a 6.2 m (20.3 ft) diameter Robbins Crossover (XRE) TBM broke through into an underground chamber, marking the completion of the first TBM-driven tunnel in Albania. The TBM, operated by contractor Limak, was also the first Crossover machine to operate in Europe, and bored through geology including ophiolite, sandstone, breccia and siltstone flysch.

On May 3, 2018 a 6.2 m (20.3 ft) diameter Robbins Crossover (XRE) TBM broke through into an underground chamber, marking the completion of the first TBM-driven tunnel in Albania. The TBM, operated by contractor Limak, was also the first Crossover machine to operate in Europe, and bored through geology including ophiolite, sandstone, breccia and siltstone flysch.

“The cutterhead and cutters have achieved outstanding performance,” said Engin Gur, TBM Manager for Limak. The TBM achieved rates as high as 648 m (2,126 ft) per month in April 2018, and as much as 37.4 m (122.7 ft) in one day. The Crossover TBM did not encounter high-pressure water and was thus used in hard rock Double Shield mode throughout tunneling.

“The TBM performed very well, as did a Robbins-supplied adit conveyor that operated in a 180-degree continuous curve. It was impressive,” said Max Walker, Robbins Field Service Superintendent. Several field service personnel remained onsite throughout operation of the TBM to provide guidance and trouble-shooting.

“The TBM performed very well, as did a Robbins-supplied adit conveyor that operated in a 180-degree continuous curve. It was impressive,” said Max Walker, Robbins Field Service Superintendent. Several field service personnel remained onsite throughout operation of the TBM to provide guidance and trouble-shooting.

The machine was launched in November 2016 following Onsite First Time Assembly (OFTA), which enabled the machine to be initially assembled at the jobsite. The crew ramped up production slowly over the next 230 m (755 ft). “Ground conditions were good and we did very few cutter changes—only 20 cutters were used during the bore,” said Walker. Two-stage grouting was carried out as the TBM bored and lined the tunnel in three 8-hour shifts. “The personnel on this project have created a friendly work environment; they’ve made it enjoyable coming to work each day. They’re good guys to work with,” he added.

While the TBM did not need to be sealed, the unique machine design took into account a predicted high risk of water inflows. The Crossover XRE machine used a belt conveyor and not a screw conveyor for muck removal, so the muck chute needed to be able to be sealed off in the case of an inrush of water. The bulkhead was thus designed with a large sealing gate just above the belt conveyor. These pressure-relieving gates could also be used in a semi-EPB mode: As the pressure built in the cutting chamber, the gate would then be opened by the pressure, and material would spill onto the belt. As the pressure lowered, the gates would then automatically close, again sealing off the chamber. In extreme cases, the gates could be sealed and the probe/grout drills could be used to drill, grout, and seal off water. Additionally, the gripper shoes and inner telescopic shield were designed with inflatable seals to further protect against inrushes of water.

While the TBM did not need to be sealed, the unique machine design took into account a predicted high risk of water inflows. The Crossover XRE machine used a belt conveyor and not a screw conveyor for muck removal, so the muck chute needed to be able to be sealed off in the case of an inrush of water. The bulkhead was thus designed with a large sealing gate just above the belt conveyor. These pressure-relieving gates could also be used in a semi-EPB mode: As the pressure built in the cutting chamber, the gate would then be opened by the pressure, and material would spill onto the belt. As the pressure lowered, the gates would then automatically close, again sealing off the chamber. In extreme cases, the gates could be sealed and the probe/grout drills could be used to drill, grout, and seal off water. Additionally, the gripper shoes and inner telescopic shield were designed with inflatable seals to further protect against inrushes of water.

With the breakthrough now complete, grouting will continue behind the TBM segments. No additional lining will be added, and the tunnel is expected to become operational by May 2019.

The 6.7 km (4.2 mi) long Moglicë headrace tunnel is part of the Devoll Hydropower Project, a Build-Own-Operate-Transfer (BOOT) scheme to construct two hydropower plants along the Devoll River, named Moglicë and Banja. The project is owned by the Norwegian power company Statkraft AS. The completed Devoll Hydropower Project will increase Albania’s electricity production by 17% and will have an installed capacity of 242 MW.

The 6.7 km (4.2 mi) long Moglicë headrace tunnel is part of the Devoll Hydropower Project, a Build-Own-Operate-Transfer (BOOT) scheme to construct two hydropower plants along the Devoll River, named Moglicë and Banja. The project is owned by the Norwegian power company Statkraft AS. The completed Devoll Hydropower Project will increase Albania’s electricity production by 17% and will have an installed capacity of 242 MW.

Image 1: A 6.2 m (20.3 ft) Robbins Crossover (XRE) TBM broke through at the Moglice Headrace Tunnel in Devoll, Albania on May 3, 2018.

Image 2: The breakthrough of the Robbins Crossover (XRE) TBM marks the completion of the first TBM-driven tunnel in Albania.

Image 3: The TBM bored a 6.7 km (4.2 mi) headrace tunnel for the Devoll Hydropower project, advancing at rates of up to 648 m (2,126 ft) per month.

Image 4: Robbins Field Service personnel assisted contractor Limak throughout the project with guidance and trouble-shooting.

trenchless projects

Workhorse Machine makes progress in Difficult Ground

A rebuilt Robbins 3.5 m (11.5 ft) diameter Main Beam TBM has yet another milestone to add to its storied career: an unexpected cavern, encountered and successfully passed through.

A rebuilt Robbins 3.5 m (11.5 ft) diameter Main Beam TBM has yet another milestone to add to its storied career: an unexpected cavern, encountered and successfully passed through.

Contractor Eiffage Civil Engineering is operating the machine, which launched in 2017 for the Galerie des Janots project in La Ciotat, France. The cavern, studded with stalactites and stalagmites and measuring 8,000 cubic meters (283,000 cubic ft) in size, was grazed on the tunneling operation’s left side. The crew named the cavern “grotte Marie Lesimple” after their site geologist.

“We hit the corner of it. To cross it, we had to erect a 4 m (13 ft) high wall of concrete so the TBM would have something to grip against,” explained Marc Dhiersat, Project Director of Galerie des Janots for Eiffage. A small door allowed access inside the cavity, which formed naturally at a point 60 m (200 ft) below the surface. The TBM was started up and was able to successfully navigate out of the cavern in eight strokes without significant downtime to the operation.

“This is certainly unusual, to come across a cavern of this size and significance. It is somewhat related to the geology, with karstic and volcanic formations having the most potential for underground cavities,” said Detlef Jordan, Robbins Sales Manager Europe. Karst cavities were a known risk during the bore, but the cavern was not shown in vertical borehole reports conducted from the surface along the alignment.

“This is certainly unusual, to come across a cavern of this size and significance. It is somewhat related to the geology, with karstic and volcanic formations having the most potential for underground cavities,” said Detlef Jordan, Robbins Sales Manager Europe. Karst cavities were a known risk during the bore, but the cavern was not shown in vertical borehole reports conducted from the surface along the alignment.

A further 1.8 km (1.1 mi) will need to be tunneled before the 2.8 km (1.7 mi) tunnel is complete. “It is possible there could be more unknown caverns. We have a geotechnical BEAM system on the machine, and are conducting probe drilling, shotcreting, and maintenance in a separate shift,” said Dhiersat. The BEAM system, standing for Bore-tunneling Electrical Ahead Monitoring, is a ground prediction technique using focused electricity-induced polarization to detect anomalies ahead of the TBM.

The crew encountered difficult ground conditions early on in the bore, consisting of limestone with powdery clays. “When the machine is boring it does well. We have good production and it’s a good machine for hard rock. But sometimes it’s not hard rock that we encounter,” said Dhiersat. The weak rock and clay conditions necessitated ground support including resin-anchored bolts and rings in bad ground, topped with a 10 to 15 cm (4 to 6 in) thick layer of shotcrete. Despite five months of poor ground conditions, Eiffage is optimistic that conditions will improve and the tunnel will be complete in the next four to five months.

Galerie des Janots is one of the fourteen operations designed to save water and protect resources, which are being carried out by the Aix-Marseille-Provence metropolis, the water agency Rhône Mediterranean Corsica, and the State Government. The future Janots gallery will replace existing pipelines currently located in a railway tunnel—these original pipes have significant deficiencies with estimated water losses of 500,000 cubic meters (132 million gallons) per year.

The completed tunnel will pass under Le Parc National des Calanques, with cover between 15 and 180 meters (50 to 600 ft), in order to replace the pipes that are currently being utilized for the water supply networks. “The current pipes have a capacity of transit limited to 330 liters (87 gallons) per second, which is largely insufficient in the summer period. The objective of the operation is to secure the lines and increase capacity to 440 liters (116 gallons) per second,” said Dhiersat.

Image 1: The Robbins TBM encountered an unexpected cavern measuring 8,000 cubic meters (283,000 cubic ft) in size.

Image 2: Despite continued difficult ground, contractor Eiffage is confident in the Robbins TBM performance and optimistic that the tunnel can be completed in four to five months.

Industry News, trenchless projects

The University of Central Florida purchased a Vac-Tron AIR 373 SDT vacuum excavator in 2016 and shared the benefits this unit has created for the facilities.

The University of Central Florida purchased a Vac-Tron AIR 373 SDT vacuum excavator in 2016 and shared the benefits this unit has created for the facilities.

“We didn’t have an initiative on campus to do soft digging and locating, so we went looking for a solution and Vac-Tron came out to be the best value for our money,” said Anthony Lugo, UCF Utility Supervisor.

Project Descriptions

Some of the initiatives that UCF utility workers handle daily include identifying and mapping the location of utility lines.

“We have a lot of old utility lines in the ground that haven’t been located in many decades. They have never been marked properly, and it is our job to find them, mark them, and put them on the map. Finding those lines can be time consuming and intrusive to the property. But the biggest obstacle, when you are part of the utility crew, is safety, you don’t want to hit electrical lines with a shovel.” said Lugo.

The utility crew is also responsible for emergency water line breaks. “Prepping the area for a water line break repair is a tedious job and time is of the essence.” added Lugo.

Solution

The Vac-Tron AIR 373 SDT vacuum excavation unit. The UCF AIR unit is powered by an 83 HP Yanmar diesel engine and comes standard with a 300-gallon debris tank, air pressure of 150 CFM at 170 PSI, hydraulically operated full-open rear door with auto engage safety latch, and one 100-gallon water tank. This unit also has the Patented Remote Debris Tank, which collects the dry material and then can be positioned back over the hole to put back into place without causing much disruption to the surroundings.

Upgrading from traditional methods of excavation, an excavator or hand shovel, to a Vac-Tron unit has greatly increased efficiency for the UCF utility crew. “It made things faster, it made things safer. It saves us a lot of time, what used to take 4-6 hours, now only takes 1-2 hours. We aren’t spending any unnecessary time doing a job.” said Lugo.

“The biggest thing is safety, safety is the key aspect. The Vac-Tron unit allows us to be safe in an expedited fashion. This is considered soft digging, which is just basically pulling the dirt out of the ground so you’re not striking anything. You could hit a high voltage electrical line, high pressure water or gas line, any number of things, and the Vac-Tron AIR unit helps to eliminate that.” stated Lugo.

Results

- Potholing quickly to locate old utility lines for identification and mapping

- 4-6 hour projects now take 1-2 hours

- Respond quicker to water line breaks

- Quicker repairs to water line breaks with the power of the vacuum excavator removing debris

- Cleaning of storm drains in an efficient way

- Wastewater spills quickly cleaned up

- Less intrusive to the campus’ infrastructure

- Less disruption to the environment

Multiple departments at UCF are also using the Vac-Tron unit. For example, the Landscaping and Recreation crew uses it to clean out storm drains, and the Design and Construction team will request it to locate lines for future construction on the campus. UCF has found multiple uses for the Vac-Tron unit. “This has been a godsend because we can actually find things without being as intrusive to the campus’ infrastructure. For the value we are getting, it has turned out to be priceless!” added Lugo.

Check out the full interview and video footage of the unit in action at UCF https://www.vactron.com/utility-crew-ucf-vacuum-excavation-case-study/.

Industry News, trenchless projects

HDD with Fusible PVC® pipe saves Commission $200,000

Overview

Overview

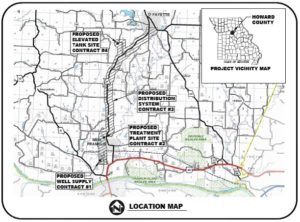

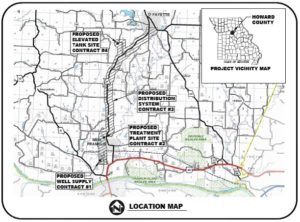

The Howard County Regional Water Commission (HCRWC) was formed in April 2008 with the intent of being a wholesale water provider for the City of New Franklin, the City of Fayette and Howard County CPWSD #1. MECO Engineering has been involved with HCRWC since day one in an effort to assist with design and funding of the required infrastructure. The necessary infrastructure consisted of an alluvial well field, water treatment plant, water tower and distribution mains.

The distribution system design consisted of approximately 68,000 feet of 12-inch waterline, 1,200 feet of 10-inch waterline and 1,200 feet of 6-inch waterline with the majority of the pipe to be installed by conventional open-cut installation. However, there was still a significant amount of the 12-inch waterline that could not be installed by conventional open-cut construction

The distribution system design consisted of approximately 68,000 feet of 12-inch waterline, 1,200 feet of 10-inch waterline and 1,200 feet of 6-inch waterline with the majority of the pipe to be installed by conventional open-cut installation. However, there was still a significant amount of the 12-inch waterline that could not be installed by conventional open-cut construction

based on environmental concerns such as creek crossings or as a result of private property disturbance agreements tied to the issuance of easements. As a result, approximately 8,800 feet of the 12-inch line would need to be installed using horizontal

directional drilling (HDD) installation methodology.

The original plans and specifications included HDPE pipe for the HDD portions of the job. However, during the bid process, Fusible PVC® pipe was allowed as an alternate material for the HDD sections. As a benefit, Fusible PVC® pipe would be able to match the bell-and-spigot PVC pipe being installed in the open cut portions of the job, while the HDPE pipe would need to be upsized in order to provide the same inside diameter. Ultimately the project allowed for two material options in the HDD portion of the job, 12-inch DR 21 Fusible PVC® pipe and 14-inch DR 9 HDPE pipe.

Bids were opened on July 8, 2015 and based on utilizing Fusible PVC® pipe for the HDD sections, C&S Construction out of New London, Missouri was the low bidder. In fact, their bid provided a $200,000 savings due to installing Fusible PVC® pipe instead of the HDPE pipe that was originally specified.

The distribution system portion of the work lasted approximately eight months with all of the Fusible PVC® pipe being installed and tested without any issues.

“We have installed Fusible PVC® pipe on multiple jobs. We really like the way it performs. For this project it allowed us to drill a smaller hole when compared to the HDPE option. Since most of these drills occurred in rock, a smaller hole provides substantial savings of both time and money.” Clinton Ray, Owner Ray’s Construction

Project Story submitted by Underground Solutions, Inc., 858.679.9551

www.undergroundsolutions.com

Industry News, trenchless projects

Fusible PVC® pipe for fault crossings, curvilinear alignments and restrained joint sections

The Los Carneros Water District Recycled Water Project was designed t o provide the Los Carneros Water District (LCWD) service area, located just south of Napa, California, with a reliable recycled water supply. This system is used to offset groundwater use during the summer irrigation season allowing more potable water to be available for critical consumption.

o provide the Los Carneros Water District (LCWD) service area, located just south of Napa, California, with a reliable recycled water supply. This system is used to offset groundwater use during the summer irrigation season allowing more potable water to be available for critical consumption.

This project included the construction of 8.6 miles of 6- to 20-inch diameter recycled water pipelines to provide a distribution system which supplies recycled water to portions of residential landscape and agricultural land within LCWD. The recycled water will be sourced from the Napa Sanitation District’s existing Soscol Wastewater Treatment Plant (WWTP). The system is located within existing road right of ways and did not require new pump stations or storage facilities. All storage and pumping requirements are met using Napa Sanitation District’s Soscol WWTP facility. The project serves approximately 115 parcels or 3,800 acres of irrigable land within the District with approximately 1,300 acre-feet of recycled water per year. Irrigation water users connect their own irrigation systems and facilities to various turnouts on the system to provide the recycled water to their private lands and fields.

The District bid Fusible PVC® pipe, with its thermally butt-fused joint, as the base bid for restrained joint areas, fault crossings and curvilinear alignments that exceeded the allowable deflection of conventional bell-and-spigot pipe. The District also allowed mechanically restrained bell-and-spigot PVC pipe, using bell restrainers with 316 stainless steel hardware for the restrained pipe lengths. The bell restrainer also needed to be wrapped in an AWWA approved four-part petrolatum tape wrap system for corrosion control. JMB Construction, the low bidder on the project, elected to use Fusible PVC® pipe in the restrained areas as the most cost-effective option.

The District bid Fusible PVC® pipe, with its thermally butt-fused joint, as the base bid for restrained joint areas, fault crossings and curvilinear alignments that exceeded the allowable deflection of conventional bell-and-spigot pipe. The District also allowed mechanically restrained bell-and-spigot PVC pipe, using bell restrainers with 316 stainless steel hardware for the restrained pipe lengths. The bell restrainer also needed to be wrapped in an AWWA approved four-part petrolatum tape wrap system for corrosion control. JMB Construction, the low bidder on the project, elected to use Fusible PVC® pipe in the restrained areas as the most cost-effective option.

Approximately 20 percent of the pipeline was constructed with Fusible PVC® pipe. Fusible PVC® pipe addressed several specific design elements that conventional bell-and-spigot PVC pipe could not. These included seismic fault crossings where the fusion joint provides a fully restrained joint that resists ‘pull-out’ during earth movement. It also included curvilinear horizontal and vertical pipeline alignments that

exceed the allowable deflection capability of bell-and-spigot joining technology. Finally, it was used as the non-corrosive restrained-joint pipeline required to resist axial thrust at fittings and appurtenances along the pipeline. Fusible PVC® pipe is the only PVC restrained joint meets the requirements of the AWWA C605 PVC pressure pipe installation standard, regardless of pipe size.

JMB Construction’s Sean Quinn commented, “JMB has utilized and installed Fusible PVC® pipe on many projects including HDD, sliplining, pipe bursting and open cut installations. This is another project in a long line of successful projects using Fusible PVC® pipe.”

Image 1: Placing the restrained, Fusible PVC® pipe length under existing utility crossings

Image 2: JMB used standard, mechanical joint ductile iron fittings with restrainer glands to assemble the pipe system

Trenchless Technology Center at Louisiana Tech University Awarded Project to Measure Styrene and Other Compounds to Capture Variation in Emissions During Pipe Rehabilitation Using the Cured‐In‐Place Pipe (CIPP) Method

Trenchless Technology Center at Louisiana Tech University Awarded Project to Measure Styrene and Other Compounds to Capture Variation in Emissions During Pipe Rehabilitation Using the Cured‐In‐Place Pipe (CIPP) Method The project is Phase 2 of a larger study and calls for measurement of styrene and other organic compounds at six CIPP installation sites, representing different pipe diameters (8”, 12”, and larger), and lengths, in order to capture variation in emissions. Measurements will be conducted before, during, and after curing at the termination manhole, as well as various locations in the surrounding outside area and inside nearby buildings. Worker exposure will also be measured via personal exposure monitors. Finally, dispersion modeling will be conducted to estimate compound concentrations at a large number of locations for a wide variety of meteorological conditions. Measured and modeled concentrations will be compared to appropriate health-based action levels to determine if any potential health risks exist for workers or citizens in the surrounding communities.

The project is Phase 2 of a larger study and calls for measurement of styrene and other organic compounds at six CIPP installation sites, representing different pipe diameters (8”, 12”, and larger), and lengths, in order to capture variation in emissions. Measurements will be conducted before, during, and after curing at the termination manhole, as well as various locations in the surrounding outside area and inside nearby buildings. Worker exposure will also be measured via personal exposure monitors. Finally, dispersion modeling will be conducted to estimate compound concentrations at a large number of locations for a wide variety of meteorological conditions. Measured and modeled concentrations will be compared to appropriate health-based action levels to determine if any potential health risks exist for workers or citizens in the surrounding communities.