Uncategorized

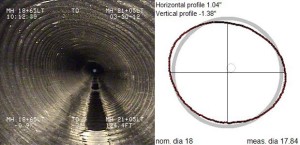

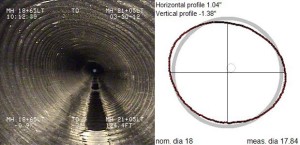

To keep pace with technology and to ensure that we meet and exceed our client’s expectations of high quality and reliability, Tri-State Utilities introduced a Laser Pipe Profiling System. The KS135 Scan Camera will revolutionize the pipe profiling process by using the “spinning laser” profiling technology. It is a 3 in 1 system where two laser diodes are integrated on either side to the conventional CCTV camera lens to perform three functions:

- Conventional CCTV video pipe inspection

- Laser profiling – precise measurement of diameter, deflection and deformation of pipe

- Crack & Joint measurement

The Rausch Laser Profiler features two laser diodes that are integrated into the KS135 Scan camera head. When these laser diodes project laser dots onto the inner pipe wall, the camera head rotates to measure the diameter and all changes via triangulation calculations. This method is called the “spinning laser” pipe profiling technology. Working in conjunction with the POSM software, the comprehensive scan generates easy to use reports to profile the pipe.

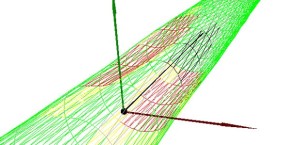

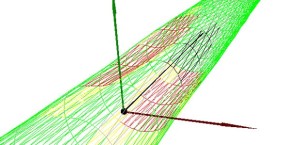

On the way into the pipe, the system is used to perform conventional CCTV video inspection, as well as measuring all joint widths. Laser measurements can be taken at any time to determine the actual pipe diameter and deflection, called a single point scan. On the way out of the pipe, the system performs a “spinning laser” scan of the entire length of the pipe. The camera head swivels perpendicular to the pipe wall and rotates at a defined speed. The Scan software continuously calculates the precise pipe diameter and all deflections and deformations in the pipe profile. One the run is completed, the software instantly generates the graphs in 2- and 3-D. This process may prove invaluable when performing Post Installation Inspection of new pipes. These graphs will show deflectio n, the average pipe diameter, and will also contain an inclinomitor for recording the grade of the pipe.

n, the average pipe diameter, and will also contain an inclinomitor for recording the grade of the pipe.

Learn more on the Tri-State Utilities website.

Uncategorized

HammerHead®, RS Technik® strategic alliance offers full suite of noninvasive pipe repair and rehabilitation solutions.

LAKE MILLS, Wis., – HammerHead Trenchless Equipment, a Charles Machine Works company, has announced it has formed a strategic alliance with RS Lining Systems, LLC, the provider of RS Technik pipe rehabilitation solutions in the Americas. This will complete the suite of nonintrusive rehabilitation solutions available to HammerHead customers.

A global leader of CIPP technology, RS Technik manufactures rehabilitation product lines such as RS MaxPatch®, a fast, trenchless, selective point repair system for pipes 3 to 48 inches in diameter.

Joanne Carroll, RS Lining Systems senior vice president, said: “It’s exciting for us to be partnered with HammerHead. HammerHead is a significant leader in the industry, who provides trenchless solutions that effectively and economically address mounting underground infrastructure issues. Together we will significantly enhance the value to customers by delivering the industry’s most complete package of sustainable engineered solutions for trenchless pipeline repair.”

Rick Johnson, HammerHead interim president and CEO of Charles Machine Works, agreed: “Every RS Technik solution is fundamentally grounded in providing proven, effective and reliable alternatives to traditional pipe repair. Combine their products with our HammerHead HydraLiner CIPP line of installation equipment and consumables—not to mention our full line of pipe bursting equipment— and our customers have access to every advantage possible for restoring gravity and pressure sewer, water and industrial pipe infrastructures.”

“Our companies share that same entrepreneurial spirit and a passion for creating solutions for the underground infrastructure industry, which makes this union such a natural fit. We’re sure our customers will see that right away. Both companies are solution oriented and innovation driven. In the future, we’re even looking forward to the possibility of our R&D teams cooperating on the next generation of trenchless solutions.”

RS MaxPatch is the first of many solutions HammerHead customers now have access to. Already available for sale through HammerHead sales representatives and HammerHead’s retail site www.hydraliner.com, RS MaxPatch is a safe, proven CIPP solution used to repair short sections of pipe. The corrosion-resistant fiberglass composite system repairs and seals isolated pipe defects such as cracks, leaks, joint offsets, corrosion and root intrusion. The high-strength resin and fiberglass matrix provides unmatched structural strength, while its thin, tapered profile and smooth finish help maintain or increase flow capacity.

HammerHead Trenchless Equipment of Lake Mills, Wisconsin, USA, manufactures a full line of pipe bursting, pipe ramming/HDD assist, pneumatic boring equipment, HDD tooling and accessories, and CIPP lateral lining systems and consumables. All of these products are recognized around the world for their advanced design, rugged construction, long-term durability, ease of use, and reliability. HammerHead offers worldwide sales, support, service and parts through a network of authorized dealers.

RS Technik, founded in Europe, is a global leader in CIPP technology providing a comprehensive suite of pipe rehabilitation solutions for gravity sewer, pressure pipe and potable water including RS MaxPatch®, RS CityLiner®, RS CityMain®, and RS BlueLine® featuring mobile, state-of-the-art CIPP impregnation and installation equipment. Brought to the Americas 10 years ago by RS Lining Systems, LLC of Cary, North Carolina, RS Technik engineered systems provide unique solutions developed to meet the emergent needs of asset managers including performance, durability, and cost-effective sustainability of pipeline infrastructure. For more information visit www.rstechnik.us.

For more information about HammerHead products, please call 800-331-6653 or visit www.hammerheadtrenchless.com.

Established in 1902, Charles Machine Works, an employee-owned company, founded in Perry, Oklahoma, is the only manufacturer and global distributor that solely exists to make underground utility construction profitable. Our family of companies includes Ditch Witch®, Subsite® Electronics, DW/TXS®, HammerHead®, Radius® HDD, American Augers®, Trencor® and MTI® Equipment. For more information visit www.charlesmachineworks.com.

Photos captions:

1. Joanne Carroll, RS Lining Systems senior vice president

2. Rick Johnson, HammerHead interim president and CEO of Charles Machine Works

Uncategorized

Release Date: 07/30/2015

Contact Information: Davina Marraccini, 404-562-8293 (direct), 404-562-8400 (main), marraccini.davina@epa.gov

ATLANTA – The U.S. Environmental Protection Agency’s (EPA) Gulf of Mexico Program recognized the Center for Environmental & Economic Justice (CEEJ) in Biloxi, Miss., with a Second Place 2015 Gulf Guardian Award in the Environmental Justice Category. The awards ceremony was held today at the Texas State Aquarium in Corpus Christi, Texas.

For over 20 years, CEEJ has advanced environmental and social justice by working to eliminate environmental health hazards and promote economic sustainability in impacted, predominantly African-American communities through community education and training. Working in partnership with the Deep South Center for Environmental Justice at Dillard University in New Orleans, La., CEEJ has forged a new culturally-sensitive training model: the Minority Worker Training Program. The Minority Worker Training Program offers neighborhood residents impacted by natural disasters opportunities to join forces with local construction workers and environmentalists and proactively clean up their neighborhoods by removing environmental contaminants from sediment, soil, homes and buildings. This program has resulted in unparalleled partnership between labor, environmental and community organizations, and academia.

“This is the 13th year of the Gulf Guardian Awards, and I am proud to say that each year the winners in all categories have represented the very best of environmental accomplishments in the Gulf of Mexico,” said Diane Altsman, chief of staff for the Gulf of Mexico Program. “The Gulf of Mexico Program partnership works to improve the environmental health of the Gulf, and the Gulf Guardian Awards is an important way for us to recognize these valuable efforts.”

CEEJ has conducted numerous community education campaigns in impacted communities in all three coastal counties along the Mississippi Gulf Coast to increase public awareness of various pollutants, including lead and creosote. As an example, CEEJ worked with the Turkey Creek community in Gulfport, Miss., to help residents address their concerns associated with the Cavenham Forest Industries (CFI) plant. CFI operated a plant producing wood products and used creosote, a possible human carcinogen, for the treatment of these products to retard deterioration. CEEJ worked with residents in Turkey Creek to complete health surveys and a risk assessment.

The Gulf of Mexico Program initiated the Gulf Guardian awards in 2000 as a way to recognize and honor the individuals, businesses, community groups and agencies that are taking positive steps to keep the Gulf healthy, beautiful and productive. First, second and third place awards are given in seven categories: individual, business/industry, youth environmental education, civic/nonprofit organizations, cultural diversity/environmental justice, partnership and bi-national efforts.

The Gulf of Mexico Program began in 1988 to protect, restore and maintain the health and productivity of the Gulf of Mexico ecosystem in economically sustainable ways. The Program is underwritten by the EPA and is a non-regulatory, inclusive consortium of state and federal government agencies and representatives of the business and agricultural community, fishing industry, scientists, environmentalists, and community leaders from all five Gulf states. The Program seeks to improve the environmental health of the Gulf in concert with economic development.

More information about the Gulf of Mexico Program: www.epa.gov/gmpo

Connect with EPA Region 4 on Facebook: www.facebook.com/eparegion4

And on Twitter: @EPASoutheast

Uncategorized

NASTT turns 25 in 2015! What was happening 25 years ago?

On July 26, 1990, General Hospital recorded its 7,000th episode.

On July 27, 1990, Zsa Zsa Gabor began a three day jail sentence for slapping a Beverly Hills police officer.

On July 30, 1990, the first Saturn automobile rolled off the assembly line.

Check in every Friday in 2015 when NASTT posts more fun facts about 25 years ago…

Uncategorized

Raedlinger Primus Line Job Report:

Client:

Naval Facilities Engineering Command (NAVFAC), Mechanicsburg, PA

Year of Construction:

October 2014

Type of Project:

• Renewing existing 6 inch, 8 inch, and 12 inch cast iron water mains

• Upgrading the water mains from 65 psi operating pressure to 95 psi

Our Services:

• Delivery of the flexible 6 inch, 8 inch, and 12 inch Primus Liner with NSF/ANSI 61 approval

• Delivery of the corresponding end fittings with ANSI flanges (150 lbs) with NSF/ANSI 61 approval

Task:

The Naval facility located in Mechanicsburg, PA was constructed in less than two years during the WWII military expansion. The base consists of over 60 manufacturing and storage warehouses, which required a large amount of water for the manufacturing and fire protection of the base. The water supply was provided by 12 inch, 8 inch, and 6 inch cast iron distribution pipelines throughout the base.

The NAVFAC decided to rehabilitate the 70 year old water mains, because the pipes started to have failures, particularly with the freeze and thaw conditions that occur in the upper Northeast of the United States. In addition, the pipes are affected by corrosion and cracks due to brittleness. Furthermore, NAVFAC intended to potentially increase the operating pressure of the system from 65 psi to 95 psi.

Technical Details:

Host Pipe Material: Cast iron

Transported Medium: Potable water

Transported Medium: Potable water

Host Pipe Diameter: 6 inch, 8 inch, and 12 inch

Operating Pressure: 65 psi and upgrade to 95 psi

Raedlinger Primus Line® System: NSF/ANSI 61 approved system

6 inch Primus Liner with ID = 4.7 inch

8 inch Primus Liner with ID = 6.7 inch

12 inch Primus Liner with ID = 10.6 inch

Total Length: 3 miles

Number of Construction Sections: Multiple sections from 100 ft. to 1,000 ft

Rehabilitation System:

The client opted to renew the corroded water mains with the Primus Line® system, a proven solution for the trenchless rehabilitation of pressure pipelines. The three-layer composite liner consists of a NSF/ANSI 61 certified PE inner coating, a Kevlar® core to accommodate the operating pressure, and an abrasion-resistant PE outer layer to protect the Kevlar® core during the installation process. The semi-structural solution is not bonded to the host pipe, can traverse bends of up to 45 degree, and can be inserted in lengths of 3,000 ft. and

more in one single pull.

Project Description:

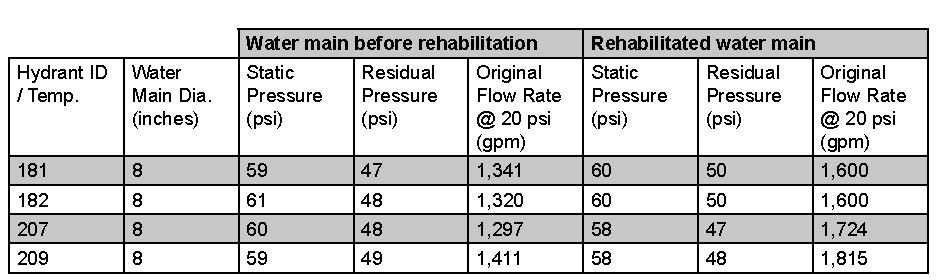

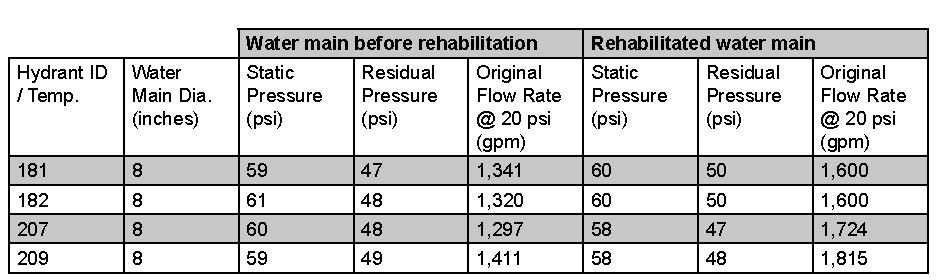

The design-build team was tasked in April 2014 with the execution of this project. The base operations needed to be maintained, the building water and fire lines needed to remain active while renewing and upgrading the existing water infrastructure. A temporary by-pass system made of 6 inch and 8 inch HDPE pipes with 10 hydrants and 20 building connections had to be set-up. The host pipes had to be CCTV inspected to identify tuberculation, sharp edges, and sediment. Metal scrapers and swabs were used to remove tuberculation and sediment. After a subsequent CCTV inspection, the pre-folded Primus Liner was installed with a pulling winch with installation speeds of 20 ft./min. The individual Primus Line sections were expanded by applying compressed air of 7 psi and terminated with low pressure Primus Line end fittings equipped with ANSI flanges (150 lbs). A hydrostatic test with 150 psi was performed and the water mains were disinfected with chlorine. A flow test was performed before and after the installation of the Primus Liner. Despite a smaller diameter, the flow

rates improved by up to 20 % because of the improved C-factor.

Visit Raedlinger Primus Line’s website for more information.

Uncategorized

Ottawa, IL (July 24, 2015) — LMK Technologies’ VAC-A-TEE® Trenchless Cleanout System now meets the newly published ASTM F3097-15 Standard. ASTM Standards are an instrumental tool used by specifying engineers throughout North America to provide guidelines that ensure the optimum results for a given product or procedure. These standards are often adopted into project specifications for the purpose of describing installation methods, materials, testing procedures, and a minimum level of quality for products and a specific scope of work.

Ottawa, IL (July 24, 2015) — LMK Technologies’ VAC-A-TEE® Trenchless Cleanout System now meets the newly published ASTM F3097-15 Standard. ASTM Standards are an instrumental tool used by specifying engineers throughout North America to provide guidelines that ensure the optimum results for a given product or procedure. These standards are often adopted into project specifications for the purpose of describing installation methods, materials, testing procedures, and a minimum level of quality for products and a specific scope of work.

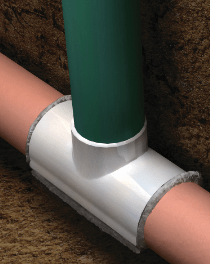

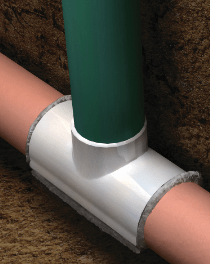

ASTM F3097-15 is a standard practice for installation of an outside sewer service cleanout through a minimally invasive small bore created by a vacuum excavator. The process begins with locating the service lateral pipe by use of a locatable sewer camera that is robotically launched from the main pipe. Once the lateral pipe is exposed, a self clamping saddle is prepared with a special adhesive and lowered into the small diameter bore hole until it contacts the lateral sewer service pipe; a downward force is applied to the riser pipe causing the side walls of the saddle to spread and encompass more than 50-percent of the host pipe.

“We are very excited to have another one of our products comply with a very important industry ASTM standard. The VAC-A-TEE system, is yet another technology example of how LMK continues to drive the industry forward with high quality products”, stated Larry Kiest, President of LMK Technologies. He further explains, “The utilization of this practice greatly reduces disruption to home owners and cities. By using this method, the installation of a cleanout has a nearly unrecognizable effect on the external surface of the ground, and most homeowners aren’t even aware that it has been installed.” The standard can be viewed and purchased at http://www.astm.org/Standards/F3097.htm.

LMK Technologies, a world leader specializing in trenchless methods to renew lateral sewer infrastructure has more than 100 worldwide issued patents for its advancements in trenchless technology. Headquartered in Ottawa, IL since 1993, LMK serves the municipal and residential markets through a network of licensed and certified contractors. For more information regarding LMK please visit www.lmktechnologies.com, call 1-815-433-1275 or email info@lmktechnologies.com.

n, the average pipe diameter, and will also contain an inclinomitor for recording the grade of the pipe.

n, the average pipe diameter, and will also contain an inclinomitor for recording the grade of the pipe.