Uncategorized

<p>CALGARY, – Pure Technologies Ltd. announced that it has closed its previously announced acquisition of Wachs Valve and Hydrant Services, LLC (“Wachs Water”), a leading provider of flow control maintenance and support, leak detection, and related asset management services to the water sector in the United States.</p><p>”I’m pleased to officially welcome Wachs Water to the Pure family,” said Jack Elliott, President and CEO of the Company. “The closing of this transaction is another milestone in our Company’s history and we look forward to the synergies our two businesses will realize together. Through Wachs Water, we have enhanced our distribution channels for the deployment of our proprietary technologies and solutions, while adding significant management capabilities and field services personnel to help manage our growing water utility customer base within North America.”</p><p>As stated within the Company’s news release dated February 17, 2015, the total purchase price was US$18.5 million, consisting of US$13.5 million in cash and US$5.0 million in common shares of Pure (totalling 878,640 shares), to be issued in equal tranches on the 6-month, 12-month, and 18-month anniversaries of closing the transaction.</p><p><strong>About Wachs Water Services</strong></p><p>Wachs Water’s roots reach back 132 years to the creation of the Wachs Company in 1883. The Wachs Companies have been trusted solutions providers to water utilities for over 60 years. Wachs Water Services was founded in 2001, as a service company focused on helping water utilities increase control of their aging distribution networks. Wachs Water currently provides the following services to the water and wastewater pipeline sector:</p><p style=”margin-left: 15pt;”>· <em><u>Information Management</u></em><em>: Developing and maintaining GIS databases on water and wastewater flow control systems;</em></p><p style=”margin-left: 15pt;”>· <em><u>Valve assessment, maintenance and flow control</u></em><em>: Helping utilities to understand the operation of their valve systems and to reduce the consequence of pipe failure through timely and appropriate valve control in the event of a failure;</em></p><p style=”margin-left: 15pt;”>· <em><u>Leak Detection</u></em><em>: Providing leak detection and non-revenue water management services to water agencies;</em></p><p style=”margin-left: 15pt;”>· <em><u>Wastewater collection system assessment and prioritization</u></em><em>: Providing a multi-technology assessment capability to help owners prioritize cleaning and CCTV inspections.</em></p><p>For additional information on Wachs Water, please visit: <a href=”http://www.wachsws.com/” target=”_blank”>www.wachsws.com</a></p><p><strong>About Pure Technologies Ltd.</strong></p><p>Pure Technologies Ltd. is an international asset management, technology and services company which has developed patented technologies for inspection, monitoring and management of critical infrastructure around the world. Pure’s business model incorporates four distinct but complementary business streams:</p><p style=”margin-left: 15pt;”>· <em>Sales of proprietary monitoring technologies for pipelines, bridges and structures;</em></p><p style=”margin-left: 15pt;”>· <em>Recurring revenue from data analysis, site maintenance, and from technology licensing;</em></p><p style=”margin-left: 15pt;”>· <em>Premium technical services including </em><a href=”http://www.puretechltd.com/applications/pipelines/index.shtml” target=”_blank”><em>pipeline inspection</em></a><em>, </em><a href=”http://www.puretechltd.com/solutions/leak_detection/index.shtml” target=”_blank”><em>leak detection</em></a><em> and </em><a href=”http://www.puretechltd.com/solutions/condition_assessment/index.shtml” target=”_blank”><em>condition assessment</em></a><em>;</em></p><p style=”margin-left: 15pt;”>· <em>Specialized engineering services in asset management, non-revenue water and condition assessment for water and wastewater infrastructure.</em></p><p>® Registered Trademarks, property of Pure Technologies Ltd.</p><p>SOURCE Pure Technologies Ltd.</p><p>To find out more about Pure Technologies Ltd. (TSX: PUR), visit their website at <a href=”http://www.puretechltd.com” target=”_blank”>www.puretechltd.com</a> or contact Paul Moon, Investor Relations; (403) 266-6794 or investor.relations@puretechltd.com.</p>

Uncategorized

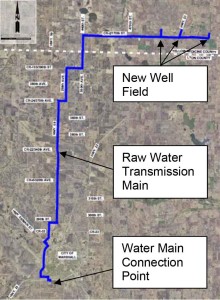

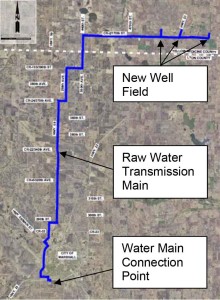

Cities all over the country are challenged with maintaining adequate water supplies to meet  the demands of their customer base. Facing new water quality regulations that limited production from existing water wells, Marshall Municipal Utilities (MMU) in southwestern

the demands of their customer base. Facing new water quality regulations that limited production from existing water wells, Marshall Municipal Utilities (MMU) in southwestern

Minnesota developed several new wells to ensure reliable future water supply to Marshall residents. The new wells are located approximately 15 miles north of the City of Marshall. Conveying water from the new wells to the City required approximately 27 miles of raw water transmission pipelines ranging in diameter from 12-inch to 24-inch.

While most of the transmission main on the project was installed by traditional open-cut methods using bell-and-spigot PVC pipe, approximately 8,000 LF of Fusible PVC® pipe was used for crossings that required trenchless installation. Trenchless construction consisted primarily of directionally drilling Fusible PVC® pipe under waterways and road crossings. Because much of the alignment was within Minnesota Department of Transportation (MNDOT) controlled right-of-ways, Fusible PVC® pipe was drilled under many roadways to

avoid disturbance and potentially expensive restoration.

Jeff Larson of MMU had used Fusible PVC® pipe on past projects and liked the approach of maintaining material consistency between the trenchless and open-cut sections of the

project. Based on the findings of a recent study from South Dakota State University (SDSU), MMU and its consultant, DGR Engineering, also decided to use approximately 2,000 feet of 24-inch Fusible PVC® pipe in an area of open-cut construction near high pressure petroleum pipelines. The SDSU Study found that Fusible PVC® pipe outperforms other thermoplastic pipe systems when exposed to petroleum products.

With a lot of interest from regional contractors, favorable bid pricing allowed the project to move forward with Winter Brothers Underground as the prime contractor and MinnComm Underground Utility Construction as the directional drilling contractor. Overall, Fusible PVC® pipe was directionally drilled or sliplined through steel casings on more than 40 separate trenchless crossings along the transmission main alignment.

Pipeline Details and Project Summary

Project Location: Sandnes Raw Water Main, Marshall, MN

Length, Pipe Size: 9,910 LF; 12”,16”, & 20” DR18, 20” & 24” DR21, and 24” DR25

Installation: HDD, Slipline, Open-Cut

Owner: Marshall Municipal Utilities

Engineer: DGR Engineering

Contractors: Winter Brothers Underground, Inc. (prime), MinnComm Underground Utility Construction (HDD sub)

UGSI Contact: Dan Christensen (715) 206-0518, dchristensen@undergroundsolutions.com

Underground Solutions (UGSI) provides infrastructure technologies for water/wastewater applications. UGSI’s Fusible PVC® products, including Fusible C-900®, Fusible C-905® and FPVC®, contain a patented PVC formulation that, when combined with UGSI’s patented

fusion process, results in a monolithic, fully-restrained, gasket-free, leak-free piping system. UGSI’s Duraliner™ is a patented, close-fit pipeline renewal system creating a stand-alone structural liner.

Uncategorized

May 4, 2015 – LAKE MILLS, Wisc.– Whether inspecting pipe laterals for cleaning, repair or  inspection, plumbing specialists now have a one-touch lateral camera system that supports a wide range of pipe sizes with a highly durable yet comparatively inexpensive self-contained unit. The 200-foot pushrod capability of the new PortaVision 3 from HammerHead Trenchless Equipment can be increased from its standard system to a 300- or 400-foot capability simply by changing out its premium fiberglass spiral-wound pushrod reels – eliminating the cost of duplicate system components to meet the needs of all jobsite applications.

inspection, plumbing specialists now have a one-touch lateral camera system that supports a wide range of pipe sizes with a highly durable yet comparatively inexpensive self-contained unit. The 200-foot pushrod capability of the new PortaVision 3 from HammerHead Trenchless Equipment can be increased from its standard system to a 300- or 400-foot capability simply by changing out its premium fiberglass spiral-wound pushrod reels – eliminating the cost of duplicate system components to meet the needs of all jobsite applications.

“I think the PortaVision 3 system offers users two huge values,” said Matt Gabrielse, HammerHead lateral products support specialist. “One is the increased versatility they get by simply swapping out reels for longer runs. The other is the increased life they’ll enjoy from its premium fiberglass spiral-wound pushrods.”

Pushrods are subject to the most abuse during inspection work. The fiberglass spiral-wound material used to make PortaVision 3 Premium Push Rods lasts up to four times longer than less durable push rod materials.

Wheeled camera skids are available for use with pipe diameters 8 to 12 inches.

The 10.4-inch hi-res LCD monitor is easily removed from the frame for quick mobilization. For one-touch recording of up to seven hours of video and sound, operators simply push the PortaVision3 On-Demand recording button.

Hardwired connection to the monitoring unit’s integrated USB port (8 Mb USB memory device included) eliminates the need to purchase a dedicated computer notebook, netbook or laptop. The connection ensures high-quality recording. No Bluetooth or Internet connection is required.

Hardwired connection to the monitoring unit’s integrated USB port (8 Mb USB memory device included) eliminates the need to purchase a dedicated computer notebook, netbook or laptop. The connection ensures high-quality recording. No Bluetooth or Internet connection is required.

The PortaVision 3 is available from HammerHead Trenchless Equipment or from authorized dealers, worldwide. Authorized dealers can be found on the web at www.hammerheadtrenchless.com or by calling 800.331.6653. (International: + [1] 920.648.4848). Equipment pricing and information is also available online at www.hydraliner.com.

Photo 1 Caption: PortaVision 3 one-touch lateral camera system from HammerHead

Photo 2 Caption: Easy to use interface includes one touch recording.

Uncategorized

NASTT turns 25 in 2015! What was happening 25 years ago?

From May 2-4, the first talks between the government of South Africa and the African National Congress took place.

On May 4, Latvia declared independence from the Soviet Union.

ON May 5, Craig Perret aboard Unbridled wins the 116th Kentucky Derby in 2:02.

Check in every Friday in 2015 when NASTT posts more fun facts about 25 years ago…

Uncategorized

In water and wastewater systems, an “asset” is a component of a facility with an independent physical and functional identity and age (e.g., pump, motor, sedimentation tank, main). The renewal and replacement of the assets that make up our nation’s water infrastructure is a constant and ongoing task. To efficiently manage this important part of a utility’s business, many have turned to asset management. This approach has gained recognition all across the world—and across all infrastructure heavy sectors—for its effectiveness in maximizing the value of capital as well as operations and maintenance expenditures.

You can read more about sustainable water asset management practices on the EPA website here.

NASTT’s Online Trenchless Library has dozens of technical papers that discuss asset management. You can browse the titles here.

Uncategorized

Rainfall-derived infiltration and inflow (RDII) is the increased portion of water flow in a sanitary sewer system that occurs during and after a rainfall as a source of operating problems in sanitary sewer systems. RDII is the main cause of sanitary sewer overflows (SSO) to

- basements,

- streets, or

- nearby receiving waters.

The extent of infiltration also correlates with the condition of aging sewers. Excessive RDII can also cause serious operating problems at wastewater treatment facilities. There is a need to develop methodologies and computer tools to assist communities in developing an optimal capital improvement program, while providing flexibility for future improvements.

Continue reading on the EPA website.