Blog, Industry News, trenchless products

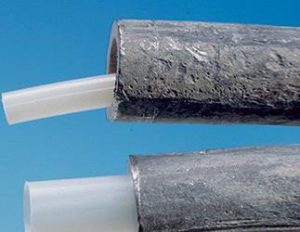

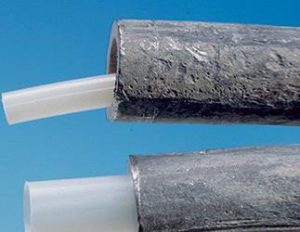

Ottawa, IL, June 20, 2017 – LMK Technologies is proud to announce its continued five year partnership with Flow-Liner as a National Distributor of the Neofit System. The updated Neofit system is a durable, green, and cost effective method of trenchless rehabilitation of potable water lines, providing almost instantaneous results with increased flow rate and minimal diameter loss while creating a barrier from lead, preventing contamination and making water safe for consumers.

Ottawa, IL, June 20, 2017 – LMK Technologies is proud to announce its continued five year partnership with Flow-Liner as a National Distributor of the Neofit System. The updated Neofit system is a durable, green, and cost effective method of trenchless rehabilitation of potable water lines, providing almost instantaneous results with increased flow rate and minimal diameter loss while creating a barrier from lead, preventing contamination and making water safe for consumers.

“LMK is very excited to continue partnership with Flow-Liner,” says Larry Kiest, Jr., President, CTO and Founder of LMK Technologies. “We look forward to promoting this technology with our highly skilled network of licensed contractors and distributors so water utilities across the country can benefit from improved water quality and meet the demand for renewed water service lines, complimenting the rise in rehabilitation of water mains.”

Neofit+ Plus System is a non-invasive pipe lining system especially designed for small diameter potable water service piping. The Neofit+ Plus Liner seals small leaks and pinholes in 1/2″ thru 2″ ID service piping. It also acts as a barrier between existing lead piping and potable drinking water. The Neofit+ Plus Liner is NSF-61 approved and has been tested to a minimum 50+ year life expectancy. LMK is promoting the advanced Neofit processing equipment, now providing lining lengths up to 300 feet. The technique necessitates minimal disturbance of surrounding ground, removing the risk of damaging other utility services. The absence of chemicals required makes it environmentally friendly and allows consumers to receive immediate return to service post processing.

Neofit+ Plus System is a non-invasive pipe lining system especially designed for small diameter potable water service piping. The Neofit+ Plus Liner seals small leaks and pinholes in 1/2″ thru 2″ ID service piping. It also acts as a barrier between existing lead piping and potable drinking water. The Neofit+ Plus Liner is NSF-61 approved and has been tested to a minimum 50+ year life expectancy. LMK is promoting the advanced Neofit processing equipment, now providing lining lengths up to 300 feet. The technique necessitates minimal disturbance of surrounding ground, removing the risk of damaging other utility services. The absence of chemicals required makes it environmentally friendly and allows consumers to receive immediate return to service post processing.

To learn more about the Neofit+ Plus System, please contact LMK at 815-640-9302.

LMK Technologies, a world leader specializing in trenchless methods to renew subterranean pipeline infrastructure, has more than one hundred U.S. and foreign issued patents for its advancements in trenchless technology. Headquartered in Ottawa, IL since 1993, LMK serves the municipal, commercial and residential markets through a network of licensed and certified contractors. For more information regarding LMK, please visit www.lmktechnologies.com, call 1-815-640-9302 or email info@lmktechnologies.com.

Blog, Industry News, trenchless products

Truck vacs offer power, scalable tank capacity and reliability for high-production contractors

Truck vacs offer power, scalable tank capacity and reliability for high-production contractors

GREENVILLE, S.C. — June 7, 2017 — McLaughlin has extended its Vermeer MEGA VAC vacuum excavator product line with new PTO-driven options. The Vermeer VXT truck series was developed in response to industry requests for a productive vacuum excavator that meets weight regulations and that is backed by the support of the Vermeer dealer network.

Ideal for utility and distribution contractors, the VXT Series is a reliable, cost-effective solution for high-production potholing crews. The new MEGA VAC PTO-driven vacuum excavators come in three standard spoil capacity options: the VXT6 (6-yard), the VXT8 (8-yard), and the VXT10 (10-yard).

“The new VXT truck series is designed for the production-minded utility contractor who is focused on maximizing uptime and maintaining a safe and productive jobsite,” said Jeff Wage, vice president at McLaughlin. “These machines fit that niche of being able to do the work that’s required at a price point high-production contractors can justify.”

“The new VXT truck series is designed for the production-minded utility contractor who is focused on maximizing uptime and maintaining a safe and productive jobsite,” said Jeff Wage, vice president at McLaughlin. “These machines fit that niche of being able to do the work that’s required at a price point high-production contractors can justify.”

Proven for potholing

The VXT series is a 6-inch (15.2 cm) system featuring spoil tank capacities ranging from 1,200 to 2,000 gallons (4542.5 to 7570.8 L) and a standard option of 800 gallons (3028.3 L) of fresh water. For off-road applications, larger spoil tank capacities are available from 2,200, 2,600 and 3,000 gallons (8327.9, 9842.1 and 11,356.2 L).

“Contractors asked for a 6-inch vacuum excavator for potholing performance and the ability to work in certain rocky and granular ground conditions,” said Wage.

The VXT Series is powered by the industry-proven OMSI Gearbox and a ROOTS 3200 CFM (91 m3/min) blower. When the truck is put into PTO mode, the rear axle is disengaged and the OMSI gearbox becomes live to drive the ROOTS blower at 18 inches of mercury and 3200 cfm. The OMSI gearbox hydraulically provides the power to drive the 10 gpm/3,000 psi water pump as well.

The VXT Series is powered by the industry-proven OMSI Gearbox and a ROOTS 3200 CFM (91 m3/min) blower. When the truck is put into PTO mode, the rear axle is disengaged and the OMSI gearbox becomes live to drive the ROOTS blower at 18 inches of mercury and 3200 cfm. The OMSI gearbox hydraulically provides the power to drive the 10 gpm/3,000 psi water pump as well.

The new CAN Control system allows for two-way communication between the remote control and the vacuum excavator. With the CAN Control system operators can start the MEGA VAC, control the idle speed, dump spoils, open the rear door and control full boom operation, which helps contractors increase jobsite productivity. The controls also give a full readout on performance of the engine, the blower and the water pump.

The new Vacuum Neutral feature adds to operator safety and productivity on the jobsite. In Vacuum Neutral mode, the blower breathes free air and stops suction without the need to close the hydraulic gate valve in the boom. This allows an operator to work safely near the boom without having to shut the vacuum off.

Capacity that will scale

Utility contractors, gas distribution contractors and the large contractors building fiber optic networks must balance the need for maximum spoil tank capacity with increasingly stringent weight regulations and restrictions. The VXT6 and the VXT8 MEGA VACs were designed with scalability as a top priority. Built on a 10-wheel Peterbilt chassis, the VXT6 has a 1,200-gallon (4542.4 L) spoil tank capacity and can carry up to 410 gallons (1552 L) of water and still meet weight regulations. The VXT8 has a 1,600-gallon (6056.7 L) tank capacity and can carry up to 800 gallons (3028.3 L) of fresh water. With a standard drop axle, the VXT8 weighs only 33,000 pounds (14,968.5 kg) empty on the Peterbilt 348 chassis.

“Time and time again, we hear concerns from contractors regarding overweight vehicles on the highway. Allowing units to run overweight puts both their employees and their company at risk for financial and legal repercussions,” said Wage. “By selecting the VXT6 or the VXT8, a contractor can reduce the risks and improve working conditions for their employees.”

For reassurance that the vacuum meets weight regulations, the VXT Series features the new optional Air-Weigh scale system. Incorporated into the chassis and the CAN Controls, the Air-Weigh scale system informs the operator when a truck hits its preprogrammed maximum axle weights. At the point that the truck reaches a preprogramed axle capacity, the unit will automatically enter Vacuum Neutral mode. The control panel message will allow the operator to “override” the Vacuum Neutral mode or can be programed with a security code so only a manager may authorize a system override.

All McLaughlin vacuum excavators are backed by the Vermeer dealer network. The worldwide dealer network means consistent parts availability and a knowledgeable staff wherever the job takes contractors. To learn more, visit mclaughlinunderground.com or email McLaughlin at mmole@mightymole.com.

Blog, Industry News, trenchless products

Alternative Lining Technologies (ALT) announces Ace Pipe Cleaning, a subsidiary of Carylon Corporation, as a certified installer of their cured-in-place manhole lining systems throughout the Central United States. Based out of Kansas City, MO, Ace Pipe Cleaning is one of the oldest and largest sewer contractors in the country. While their services and expertise are varied, they focus on sewer cleaning, inspection, and rehabilitation.

Alternative Lining Technologies (ALT) announces Ace Pipe Cleaning, a subsidiary of Carylon Corporation, as a certified installer of their cured-in-place manhole lining systems throughout the Central United States. Based out of Kansas City, MO, Ace Pipe Cleaning is one of the oldest and largest sewer contractors in the country. While their services and expertise are varied, they focus on sewer cleaning, inspection, and rehabilitation.

For 20 years Ace Pipe Cleaning has been the premier contractor for these services in Missouri, Kansas, Oklahoma, Texas, and Arkansas. During that time, they have maintained expertise in a rapidly advancing industry. Aging infrastructure and growing communities have forced the sewer industry to innovate products and technology that seek to maintain collection systems more efficiently. Trenchless technologies, like CIPP, have revolutionized the way communities approach rehab and the associated costs. Similarly, ALT is partnering with contractors, like Ace, to introduce a unique system for rehabilitating manholes and other vertical sewer structures.

Based on the concept of cured-in-place pipe, CIPM liners utilize coated felt and fiberglass combined with epoxy to rehabilitate structures, while stopping I/I and preventing further corrosion. The AltLiner is constructed of panels of felt, which are coated with PVC. These panels are thermally fused to form a sealed liner, custom made for each structure. Fiberglass panels are added for the structural component. The liner is then wet-out onsite and cured under steam and air pressure to conform the liner to the manhole. This creates a strong, corrosion resistant rim-to-invert liner that extends structure life by 50 years or more. Every liner is backed with a 20-year non-prorated warranty.

Alternative Lining Technologies is excited to partner with such a capable and reputable company, like Ace. ALT General Manager, Jim Rouse stated “We believe our system is the best solution for the immense corrosion problem in manholes and pump stations. We are focused partnering with respected installers, like Ace, to prove the value of the system to engineers and

collection systems.” Ace Pipe Cleaning executive, Steve Hontz, echoed Jim’s enthusiasm saying “This is a great solution for structural and hydrogen sulfide protection.”

Ace and ALT are planning demos and presentations in Missouri and Texas this summer to educate the industry about CIPM lining systems. If you’d like more information or to request a

presentation for your organization, contact Bryan Dobson at Ace Pipe Cleaning by calling 800-325-9372.

Blog, Industry News, trenchless products

Hutchinson, Kansas – StraightLine HDD, Inc. announced the implementation of an upgrade to its popular Performix Mud Mix System. At the heart of the Performix System is the centrifugal pump, which generates the best laminar flow in the industry.

Hutchinson, Kansas – StraightLine HDD, Inc. announced the implementation of an upgrade to its popular Performix Mud Mix System. At the heart of the Performix System is the centrifugal pump, which generates the best laminar flow in the industry.

The performance pump now features an upgraded silicon-carbide shaft seal. Compared to traditional ceramic seals, the new seal represents a considerable advancement in resiliency when subjected to the highly abrasive elements present in mud mixing. In field testing, silicon carbide seals improve service life by a factor of three over ceramic seals.

The Performix pump retains its lubricated housing feature, which protects the pump seal from mechanical damage if the pump ever runs dry.

The new seal is a direct, no-modification required, replacement to the existing ceramic seal.

Blog, Industry News, trenchless products

THOMPSON, CONNECTICUT USA, April 4, 2017

Numa, the world’s leading drilling technology provider, offers one of the largest ranges of DTH rock drilling hammers and bits available in the industry today. The company boasts over 110 DTH products for drilling holes 3½ to 48 inches (89 – 1219 mm) in all types of conditions, applications, and industries.

Numa works with drillers on job sites around the world to support its products and gain first hand insight for advancing DTH product design. The company holds 13 patents, with more pending, for DTH equipment capable of drilling vertical, horizontal, and reverse circulation holes. Numa products are used in over 11 industries including construction, oil & gas, mining, quarry, geothermal, water well, and many more.

Numa’s wide range of DTH products includes:

SMALL HAMMERS AND BITS

SMALL HAMMERS AND BITS

Drills holes from 3-1/2″ to 10″ (89 – 254 mm) Numa offers eighteen different small diameter hammers for diverse drilling conditions. Built specifically for longevity and penetration rate, Numa’s Patriot® hammers and bits drill at high frequency and require less air. Even against high heads of water.

MID-RANGE HAMMERS AND BITS

MID-RANGE HAMMERS AND BITS

Drills holes 7-7/8” to 20” (200 – 508 mm) Numa’s mid-range hammers and bits provide a combination of speed and life to excel against hard, abrasive and just plain nasty conditions. A simplified hammer design with less internal components promotes less vibration and smooth operation.

LARGE HAMMERS AND BITS

LARGE HAMMERS AND BITS

Drills holes 18” to 48” (457 – 1219 mm) Numa pioneered the large hammer industry and leads the market in performance and reliability. Our forward thinking designs have proven themselves again and again in demanding applications around the world.

REVERSE CIRCULATION HAMMERS AND BITS

REVERSE CIRCULATION HAMMERS AND BITS

Drills holes 5-1/4” to 36” (133 – 914 mm) Numa’s Reverse Circulation products have the unique ability to bring all cuttings up the center of the hammer and drill string to be safely collected at the surface, which is essential in today’s environmentally conscious society.

SUPER JAWS® BITS

Drills holes 5-1/2” to 42” (457 – 1066 mm) Super Jaws provides superior performance for simultaneous drilling and casing in hard rock and overburden formations. Wings extend out to drill a full diameter hole then retract to bring all tooling to the surface. No expensive tools are left in the hole and no casing teeth are required.

ABOUT NUMA

Numa provides the world’s leading drilling technology with over 110 DTH Hammer and Bit products serving 11 different industries. Our products are capable of drilling vertical, horizontal, and reverse circulation holes from 3½ to 48 inches (89 – 1219 mm) in diameter and are used in 105+ countries. We have built our customer-centric reputation on providing the highest value in products, performance and personal service available in the rock drilling industry.

Blog, Industry News, trenchless products

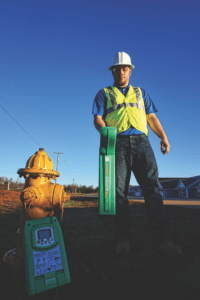

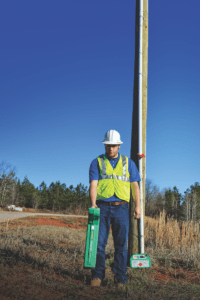

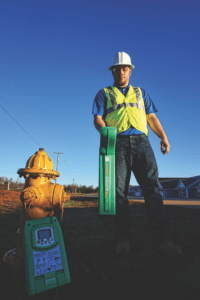

Vision LX, FLX2 and GX2 models provide fast, easy and accurate utility locates

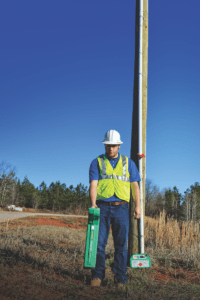

GREENVILLE, S.C. — March 22, 2017 — McLaughlin revealed a new line of underground utility locators at 2017 CONEXPO-CON/AGG, the industry’s largest trade show held in Las Vegas. The Vision locators combine proven McLaughlin technologies to ensure accuracy with new features to help contractors find underground utilities more efficiently.

GREENVILLE, S.C. — March 22, 2017 — McLaughlin revealed a new line of underground utility locators at 2017 CONEXPO-CON/AGG, the industry’s largest trade show held in Las Vegas. The Vision locators combine proven McLaughlin technologies to ensure accuracy with new features to help contractors find underground utilities more efficiently.

The Vision product line includes three models: the LX for utility contractors, the FLX2 with fault finding capabilities for power companies and secondary power contractors, and the premium GX2, designed with professional locators in mind.

“Utility contractors face a crowded underground infrastructure, unmarked utility lines and increasingly strict regulations, which makes accurate, timely locating more important than ever,” said Jeff Wage, vice president of sales at McLaughlin. “With the addition of the Vision product line, McLaughlin has an underground utility locating solution for everyone from the new utility contractor who is just starting out to the professional One Call contractor.”

Vision LX locator

The Vision LX locator has a streamlined design and simple user interface. For example, the LX combines the peak locating screen and null locating screen into one display. This allows the user to capitalize on the benefits of both functions — the accuracy of the peak mode and the user-friendliness of the null mode — without toggling back and forth between screens.

Other improvements to the display include an automatic depth and current measurement index, which automatically appears when the locator is positioned over a utility line, and a new compass icon. The compass automatically calculates the peak signal and visually informs the user of the direction of the utility path, making it easier to locate the entire line.

Vision FLX2 locator with fault finder capabilities

Vision FLX2 locator with fault finder capabilities

The Vision FLX2 has the same features and functions as the Vision LX locator plus secondary and sheaths fault-finding capabilities. Designed with power companies and secondary power contractors in mind, the FLX2 allows contractors to quickly and accurately pinpoint the location of faults in power and telecommunications cables.

Once the locator is connected to the utility line, a contractor can use an A-frame transmitter to find the fault. The contractor places the A-frame transmitter’s prongs into the ground, and the reading is sent to the receiver. If the receiver shows the signal is on the right side of the screen, the contractor proceeds forward along the utility line. If the receiver shows the signal is on the blue side of the screen, the contractor has passed the fault and is alerted to back up. Using this process, a contractor can narrow the location of the fault to within a few inches.

When used for its traditional locating capabilities, the FLX2 has five active frequency modes. Lower- frequency modes provide more accurate locates over longer distances; high-frequency modes use a powerful signal to get through resistant lines, like cast-iron pipes. The FLX2 allows the operator to adjust the frequency based on the needs of the utility line, which provides a more accurate locate.

Vision GX2 locator

Vision GX2 locator

The GX2 is the most powerful locator in the Vision product line. Using a 7-watt transmitter — instead of the standard 5-watt — the GX2 allows contractors to push the locating signal farther, which is ideal for long fiber runs or gas distribution projects with tracing wires.

To further extend the signal, the GX2 uses a dual frequency mode — that does not require Bluetoothâ — to simultaneously inject 9.5 kHz and 38 kHz signals into the utility line. When the 38 kHz signal begins to fade, the operator can use the receiver to toggle to the 9.5 kHz frequency and can continue locating.

Because some fiber providers use a custom frequency, the GX2 gives contractors the flexibility to program other frequencies into the locator for added jobsite efficiency.

McLaughlin-exclusive features

McLaughlin strives to provide the most accurate locating tools in the industry. While each Vision locator has features that make it unique, some McLaughlin-exclusive technologies come standard on all three models.

Semiautomatic and manual gain adjustment

Gain adjustment refers to the receiver’s sensitivity to the magnetic field emitted by a utility line.

“The benefit of the semiautomatic gain is that it’s a very precise method of locating — especially in congested areas — and the technology is exclusive to McLaughlin,” says Wage. “Because manual gain is a more commonly used method of locating, some contractors are hesitant to try the semiautomatic gain feature.”

All three Vision locators offer dual functionality, which means contractors can engage the semiautomatic gain on congested, urban jobsites where signal distortion is a common challenge, and use the manual gain method when working in less congested areas.

Three antennas

While competitive products use two antennas to measure depth readings, McLaughlin Vision locators use three. With the push of a button, the locator simultaneously takes depth readings from all three antennas and averages the measurements for a more accurate reading. For added durability, the antennas are rubber mounted inside the injection-molded locator case so they can stand up to tough jobsite conditions.

Inductive clamp

To help contractors be more efficient on the jobsite, the Vision locators have a waterproof inductive clamp. This means the Vision locator can lay on or partially grip the utility and produce an accurate reading, unlike competitive locators that require the clamp to fully encircle the utility, which creates extra labor for contractors.

The Vision locators come with a three-year warranty and weatherproof guarantee and are sold exclusively through the McLaughlin sales channel. To learn more, visit mclaughlinunderground.com or

email McLaughlin at mmole@mightymole.com.

Ottawa, IL, June 20, 2017 – LMK Technologies is proud to announce its continued five year partnership with Flow-Liner as a National Distributor of the Neofit System. The updated Neofit system is a durable, green, and cost effective method of trenchless rehabilitation of potable water lines, providing almost instantaneous results with increased flow rate and minimal diameter loss while creating a barrier from lead, preventing contamination and making water safe for consumers.

Ottawa, IL, June 20, 2017 – LMK Technologies is proud to announce its continued five year partnership with Flow-Liner as a National Distributor of the Neofit System. The updated Neofit system is a durable, green, and cost effective method of trenchless rehabilitation of potable water lines, providing almost instantaneous results with increased flow rate and minimal diameter loss while creating a barrier from lead, preventing contamination and making water safe for consumers. Neofit+ Plus System is a non-invasive pipe lining system especially designed for small diameter potable water service piping. The Neofit+ Plus Liner seals small leaks and pinholes in 1/2″ thru 2″ ID service piping. It also acts as a barrier between existing lead piping and potable drinking water. The Neofit+ Plus Liner is NSF-61 approved and has been tested to a minimum 50+ year life expectancy. LMK is promoting the advanced Neofit processing equipment, now providing lining lengths up to 300 feet. The technique necessitates minimal disturbance of surrounding ground, removing the risk of damaging other utility services. The absence of chemicals required makes it environmentally friendly and allows consumers to receive immediate return to service post processing.

Neofit+ Plus System is a non-invasive pipe lining system especially designed for small diameter potable water service piping. The Neofit+ Plus Liner seals small leaks and pinholes in 1/2″ thru 2″ ID service piping. It also acts as a barrier between existing lead piping and potable drinking water. The Neofit+ Plus Liner is NSF-61 approved and has been tested to a minimum 50+ year life expectancy. LMK is promoting the advanced Neofit processing equipment, now providing lining lengths up to 300 feet. The technique necessitates minimal disturbance of surrounding ground, removing the risk of damaging other utility services. The absence of chemicals required makes it environmentally friendly and allows consumers to receive immediate return to service post processing.