Industry News, trenchless projects

| Date: |

November 2018 |

| Market: |

Municipal |

| Capability: |

Cured-in-Place Pipe |

| Brand: |

Insituform |

| Location: |

United States |

When the East Central Regional Water Reclamation Facility (ECR) was interested in rehabilitating existing twin 500-ft long return activated sludge (RAS) pipes, there was concern about its condition and accessibility due to a new 42-inch plant air line that was to be constructed above it. The new air line would make future access difficult and undesirable.

The ductile iron pipe, installed in the mid-1970s, carried return activated sludge at an operating pressure of 25 psi. A solution would require not only access to the space, but also be able to withstand the pressure capabilities. InsituMain® CIPP, a type of fiber-reinforced cured-in-place pipe (CIPP), was identified as a feasible rehabilitation method. The fiber-reinforced CIPP was used along with an epoxy resin to provide a structural solution as well as stand up to the corrosive nature of the RAS effluent.

The project was met with a number of challenges during the installation process including high ground water elevation and special pit placement due to aging infrastructure. To read more about the project, view the full project brief here.

A comprehensive technical presentation will be given at the upcoming 2019 No-Dig Show in Chicago, March 17-21.

Industry News, trenchless projects

Project profile submitted by Insta-Pipe – Trenchless Pipe Repair using the Pull in Place pressure liner “PRIMUS Line”.

Client:

Client:

Washington Department of Fish and Wildlife Engineering and Installation

Partner:

Insta Pipe, Inc. – Trenchless Pipe Repair, Olympia, WA

Year of Construction:

September 2017

Type of Project:

Rehabilitation of an 8 inch AC low pressure Water Supply Line in one section of 850 feet

Our Services:

• Supply and delivery of the flexible low pressure 8 inch Primus Liner (ANSI/NSF 61 approved)

• Delivery of the 8 inch Primus Line low pressure connectors (150 psig)

Task:

Located just east of Bellingham, WA, Lake Whatcom covers 4,923.6 acres and is home to the Lake Whatcom Trout Hatchery owned by Washington State Department of Fish & Wildlife. Fishing opportunities on the lake include resident Kokanee, Largemouth and Smallmouth bass, and Yellow Perch. Fishing for resident Coastal Cutthroat Trout is currently closed due to a decline in abundance caused by siltation from logging and urban activities in their spawning tributaries. The Lake management is of mixed species with an emphasis on Trout. The task was to provide all labor, material, equipment, and permits to rehabilitate an existing 8 inch diameter asbestos concrete water supply pipe at the Department‘s Lake Whatcom Hatchery, located at 3918 South Bay Drive, Sedro Woolley, WA 98284 in Whatcom County.

Rehabilitation System:

In choosing a contractor, technique and product to rehabilitate the 8 inch, 850 feet long water supply line to the Trout Hatchery rearing ponds it was extremely important for fisheries to consider the purity of the product with an ANSI/NSF 61 approval and the minimal impact that the installation would have on the hatchery grounds, stream buffers & surrounding forestland environment and community.

Fisheries chose Insta-Pipe, Inc. to successfully install Raedlinger Primus Line to rehabilitate the pipe-line with extremely low impact rather than to dig and replace the line that ran from a supply dam, crossed a stream and paralleled that stream to its final destination at the Hatchery.

Project Description:

The decision was to install a Primus Line® DN200MD with a nominal diameter of 8 inch and a nominal design pressure of 261 psi. Since the technology works with an annular space to achieve long insertion lengths and negotiate bends, the liner provides an actual outer diameter of 7.165 inch and inner diameter of 6.693 inch. According

to the calculation of the technical department of Primus Line, the pressure rating of the system through the 45 degree bends is 148 psi and thus easily capable of accommodating the maximal operating pressure of 8 psi along the entire pipe route. To complete the system, the specially developed termination fittings were used to guarantee a durable and tensile strong connection. The Insta-Pipe team prepared the construction site and managed to complete the installation of the rehabilitation system in two days. During the entire installation a Fisheries Supervisor was on-site.

Insta-Pipe, Trenchless Pipe Repair

REPAIR SEWERS WITHOUT TRENCHING, WITH SEWER PIPE LINING

With over 25 years of experience, Insta-Pipe Trenchless Pipe Repair can repair sewer and storm lines and repair outside drain pipes with pipe lining services in WA, OR and surrounding areas. Don’t trench when you can take advantage of our pipe lining evaluation and services.

Phone: 360-943-5840 Toll Free: 866-463-9747

855 Trosper Rd SW, 108-204 Olympia, Washington 98512

www.insta-pipe.com

Raedlinger Primus Line, Inc.

112 South Tryon Street, Suite 1130

Charlotte, North Carolina 28284

info@primusline.com www.primusline.com

Industry News, trenchless projects

Project profile submitted by Insta-Pipe – Trenchless Pipe Repair using the Pull in Place pressure liner “PRIMUS Line”.

Rehabilitation of a 16” cast iron water supply line to Camp Murray Military Base, WA

Client:

US Army Corps of Engineers

Engineering and Installation Partner:

Insta-Pipe Inc. Tumwater, WA

Year of Construction:

February 2018

Type of Construction Measure:

Rehabilitation of a 16-inch cast iron water main near Tacoma, WA

Our Services:

• Delivery of the flexible 18-inch Primus Liner with NSF/ANSI 61 approval

• Delivery of the corresponding end fittings with ANSI flanges (150 lbs) with NSF/ANSI 61 approval

Situation:

In 2017 Camp Murray Military Base was replacing their water supply system due to age concerns. The majority of the system was renewed with open trench remove and replace, one of the two supply lines to the base was unable to be accessed in this manner. The supply line runs under a railway as well as Interstate 5, the main interstate highway on the west coast, making a trenchless operation the only solution. The engineers had to select from two options for this project: Primus Line, or HDPE lining. Primus Line was ultimately selected to maximize the hydraulic capacity in the line.

Rehabilitation System:

The client opted to have our installation partner, Insta-Pipe Inc. renew the water main with the Primus Line® system, a proven solution for the trenchless rehabilitation of pressure pipelines. The three-layer composite liner consists of an NSF/ANSI 61 certified PE inner coating, a Kevlar® core to accommodate the operating pressure, and an abrasion-resistant PE outer layer to protect the Kevlar® core during the installation process. The semi-structural solution is not bonded to the host pipe, can traverse bends of up to 45 degree, and can be inserted in lengths of up to 8,000 ft. in one single pull.

Project Description:

Maximizing hydraulic capacity was top priority on this project, leading to the selection of Primus Line as the rehabilitation method. The host pipe was cast iron with an internal diameter of approximately 16.38 inches, a length of 305 feet, and contained no bends. With the combination of a short run with no bends, the decision was to install a Primus Line® DN 450 MD with a nominal diameter of 18 inch and a nominal design pressure of 232 psi. Since the technology works with an annular space to achieve long insertion lengths and negotiate bends, the liner provides an actual outer diameter of 16.06 inch and inner diameter of 15.59 inch. The system has a straight-line pressure rating of 200 psi and thus capable of accommodating the maximal operating pressure of 60 psi. To complete the system, the medium pressure connectors with an operating pressure of 150 psi were used to guarantee a durable and tensile strong connection. In a first step, the two excavation pits for the installation of the Primus Line® system had to be created and the water main was disconnected from the pipeline network, opened and CCTV inspected. After that, incrustations and debris were removed with pull through metal scrapers, rubber disks and a vac truck to create a free inner diameter, which is required to make sure the liner is not damaged during the installation process. After cleaning the host pipe, the pre-folded and coiled on a transport reel Kevlar® reinforced composite liner was inserted and subsequently the liner was inflated with 7 psi to turn it into a round shape. Finally, the medium pressure termination fittings were installed and a leak test with a test pressure of 150 psi was performed and successfully completed. Concentric reducers were then used to adapt the 18-inch flanges of the Primus Line connectors down to the 16-inch flanges used in the rest of the supply system.

Insta-Pipe, Trenchless Pipe Repair

REPAIR SEWERS WITHOUT TRENCHING, WITH SEWER PIPE LINING

With over 25 years of experience, Insta-Pipe Trenchless Pipe Repair can repair sewer and storm lines and repair outside drain pipes with pipe lining services in WA, OR and surrounding areas. Don’t trench when you can take advantage of our pipe lining evaluation and services.

Phone: 360-943-5840 Toll Free: 866-463-9747

855 Trosper Rd SW, 108-204 Olympia, Washington 98512

www.insta-pipe.com

Raedlinger Primus Line, Inc.

112 South Tryon Street, Suite 1130

Charlotte, North Carolina 28284

info@primusline.com www.primusline.com

Industry News, trenchless projects

Tough TBM and Team overcome the odds with Atlanta breakthrough

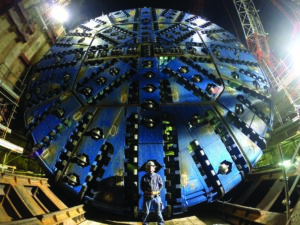

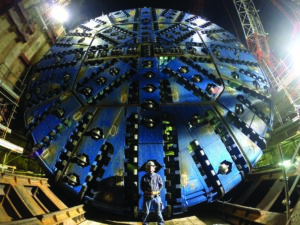

On October 4, 2018, onlookers watched as a 3.8 m (12.5 ft) diameter Robbins Main Beam TBM completed its epic journey. The TBM, christened “Driller Mike”, after local rapper and activist “Killer Mike”, overcame extremely hard rock conditions along a curving 8.0 km (5.0 mi) tunnel to bolster the city of Atlanta, Georgia, USA’s water supply.

On October 4, 2018, onlookers watched as a 3.8 m (12.5 ft) diameter Robbins Main Beam TBM completed its epic journey. The TBM, christened “Driller Mike”, after local rapper and activist “Killer Mike”, overcame extremely hard rock conditions along a curving 8.0 km (5.0 mi) tunnel to bolster the city of Atlanta, Georgia, USA’s water supply.

The new tunnel brings the Atlanta Water Supply Program one step closer to increasing the city’s water capacity to between 30 and 90 days depending on daily usage. “Our schedule for the project was very aggressive but the project team stayed together to overcome issues related to the mining of the tunnel,” said Bob Huie, Project Director for the PC Russell JV, the Construction Manager at Risk (CMAR) for the project.

The unique structure of the project team is credited with the overall project success despite challenges. “I’m proud of our team. They had obstacles and challenges and challenging ground, but they stuck together and didn’t give up, and they were successful. There was great leadership and supervision all around,” said Larry Weslowski, Tunnel Superintendent for the PC Russell JV.

The unique structure of the project team is credited with the overall project success despite challenges. “I’m proud of our team. They had obstacles and challenges and challenging ground, but they stuck together and didn’t give up, and they were successful. There was great leadership and supervision all around,” said Larry Weslowski, Tunnel Superintendent for the PC Russell JV.

The project is only the third such large construction project in the U.S. to use the CMAR structure. The PC Construction/HJ Russell JV was selected as the CMAR for the project, who then purchased the Robbins Main Beam TBM for the tunnel. The designer for the construction works including tunnel and shafts, JP2—consisting of Stantec, PRAD Group, Inc., and River 2 Tap—specified the hard rock TBM. Operation and assembly of the TBM was then sub-contracted to the Atkinson/Technique JV.

The robust TBM was assembled using Onsite First Time Assembly (OFTA) at the massive Bellwood Quarry site with help from Robbins personnel. “The guys built everything per the specs to help with scheduling. It was a challenge but there was no negativity during the process,” said Weslowski. Despite summer temperatures hitting 43 degrees Celsius (110 degrees Fahrenheit) and 100 percent humidity, the TBM was ready to launch by October 2016.

The robust TBM was assembled using Onsite First Time Assembly (OFTA) at the massive Bellwood Quarry site with help from Robbins personnel. “The guys built everything per the specs to help with scheduling. It was a challenge but there was no negativity during the process,” said Weslowski. Despite summer temperatures hitting 43 degrees Celsius (110 degrees Fahrenheit) and 100 percent humidity, the TBM was ready to launch by October 2016.

Hard granitic rock challenged the 19-inch disc cutters from the outset. “There was ground so hard that it would take eight hours to go 1.5 m (5 ft). It was between 117 and 310 MPa (17,000 and 45,000 psi) UCS. The beginning of the job was tough,” said Weslowski, but he added that once the learning curve had been overcome “they started breaking project records left and right towards the end. We got a best day of 38.4 m (126 ft). Rates just kept increasing.”

Other challenges included groundwater encountered during tunneling. “We did encounter groundwater contamination that required remediation. This remediation work was completed successfully,” said Huie.

Other challenges included groundwater encountered during tunneling. “We did encounter groundwater contamination that required remediation. This remediation work was completed successfully,” said Huie.

With tunneling complete, the USD $300 million project for the City of Atlanta’s Department of Watershed Management is on track to meet its scheduled overall completion date of September 2019. The project will turn the inactive Bellwood quarry into a 9.1 billion liter (2.4 billion gallon) raw water storage facility connecting with the Chattahoochee River and various water treatment facilities.

Image 1: The PC Russell JV and Atkinson/Technique JV celebrate the breakthrough of the Robbins TBM on October 4, 2018 in Atlanta, Georgia, USA.

Image 2: The Robbins TBM and 19-inch cutters overcame exceedingly hard granitic rock at strengths up to 310 MPa (45,000 psi) UCS.

Image 3: Crews are proud of the coordination required to overcome a host of challenges, including tight tunnel curves and contaminated groundwater that required remediation.

Image 4: The robust TBM was assembled using Onsite First Time Assembly (OFTA) at the massive Bellwood Quarry site with help from Robbins personnel.

Industry News, trenchless projects

Project profile submitted by Insta-Pipe – Trenchless Pipe Repair using the Pull in Place pressure liner “PRIMUS Line”.

Client: Southwest Suburban Sewer District

Client: Southwest Suburban Sewer District

Engineering and Installation Partner: Insta Pipe – Trenchless Pipe Repair, Olympia, WA

Year of Construction: May 2016

Type of Project: Rehabilitation of an 8 inch sewer force main with 60psi rating and vertical bends in host pipe alignment

Our services:

- Supply and delivery of the flexible low Pressure 8 inch Primus Liner (ANSI/NSF 61 approved)

- Delivery of the 8 inch Primus Line low pressure connectors (150 lbs)

Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP.

Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP.

Rehabilitation System: After an open communication with Primus Line and Insta-Pipe, the Southwest Suburban Sewer District decided to use the Primus Line® system, a flexible relining solution for the trenchless renovation of pressure pipes. The system convinces with its ability to negotiate bends, the minimally invasive construction footprint and the short installation time. In this particular case, the budget was reduced by over 50% compared to the lowest offers with CIPP and was even cheaper than the Engineer’s Estimate.

Project Description: The decision was to install a Primus Line® DN 200 ND with a nominal diameter of 8 inch and a nominal design pressure of 290 psi. Since the technology works with an annular space to achieve long insertion lengths and negotiate bends, the liner provides an actual outer diameter of 7.165 inch and inner diameter of 6.693 inch. According to the calculation of the technical department of Primus Line, the pressure rating of the system through the bends is 217 psi and thus capable of accommodating the maximal operating pressure of 60 psi along the entire pipe route. To complete the system, the low pressure connectors with an operating pressure of 150 psi were used to guarantee a durable and tensile strong connection.

In a first step, the two excavation pits for the installation of the Primus Line® system had to be created. After that the station was pumped down, the force main was dewatered and the pipe was cut for water jet cleaning and CCTV inspection. Due to the heavy incrustations in the host pipe this was performed in a 6 hour window on the first two days, because there was no bypass planned and so the pipe had to be spooled back together in the evening to empty the pump station. After one last cleaning and inspection on the third day, the pre-folded and coiled on a transport reel Kevlar® reinforced composite liner was inserted with speeds up to 15 ft. /min and inflated with 7 psi to bring it back into its round shape. Subsequently the low pressure termination fittings were installed, a pressure test with 60 psi was performed and successfully completed and the pump station was put back into service that evening. During the next morning the pits were closed and the project was successfully accomplished after a total construction time of 4 days and without shutting the pump station down for longer than a daytime window.

Insta-Pipe, Trenchless Pipe Repair

REPAIR SEWERS WITHOUT TRENCHING, WITH SEWER PIPE LINING

With over 25 years of experience, Insta-Pipe Trenchless Pipe Repair can repair sewer and storm lines and repair outside drain pipes with pipe lining services in WA, OR and surrounding areas. Don’t trench when you can take advantage of our pipe lining evaluation and services.

Phone: 360-943-5840 Toll Free: 866-463-9747

855 Trosper Rd SW, 108-204 Olympia, Washington 98512

www.insta-pipe.com

Raedlinger Primus Line, Inc.

112 South Tryon Street, Suite 1130

Charlotte, North Carolina 28284

info@primusline.com www.primusline.com

Industry News, trenchless projects

Hiroshima Heavyweight Launches on Expressway Line 5

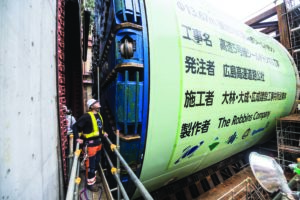

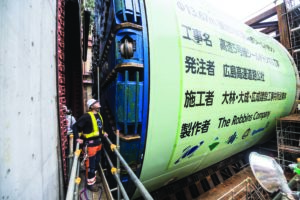

On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The design of the Slurry machine is robust in anticipation of potentially abrasive rock conditions and water pressures up to 13 bars. “The Robbins machine is very tough, for example the weight is very heavy. The cutterhead, both its material and structure, are very tough. It will not break in hard rock,” said Mr. Akai.

In preparation for the conditions, the machine was designed for 20-bar water pressure. The robust cutterhead was fitted with 20-inch and 17-inch diameter pressure compensating cutters, which utilize a patented design to effectively operate under high pressure. The joint venture intends to change the disc cutters an estimated 10 times during the bore as part of the machine’s maintenance.

Throughout the assembly and launch process the joint venture crew worked with Robbins Supervisors who assisted and provided guidance. “Robbins crews have a lot of experience; they help us every day despite the language barriers. I appreciate it,” said Mr. Akai.

The new Expressway Line 5 tunnel will directly connect Hiroshima’s urban area with a major national highway network and is expected to improve access to Hiroshima Airport. Tunnel completion is planned for 2020.

Image 1: Robbins crews assisted the contractor during Onsite First Time Assembly (OFTA) of the massive Slurry TBM in a jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long.

Image 2: The 13.7 m (44.87 ft) diameter Robbins Slurry machine launched on September 18, 2018 in Hiroshima, Japan.

Image 3: Guerin Nolasco of Robbins Field Service looks on during testing of the segment erector inside a mega-sized slurry machine at the Hiroshima Expressway Line 5 project.

On October 4, 2018, onlookers watched as a 3.8 m (12.5 ft) diameter

On October 4, 2018, onlookers watched as a 3.8 m (12.5 ft) diameter  The unique structure of the project team is credited with the overall project success despite challenges. “I’m proud of our team. They had obstacles and challenges and challenging ground, but they stuck together and didn’t give up, and they were successful. There was great leadership and supervision all around,” said Larry Weslowski, Tunnel Superintendent for the PC Russell JV.

The unique structure of the project team is credited with the overall project success despite challenges. “I’m proud of our team. They had obstacles and challenges and challenging ground, but they stuck together and didn’t give up, and they were successful. There was great leadership and supervision all around,” said Larry Weslowski, Tunnel Superintendent for the PC Russell JV. The robust TBM was assembled using Onsite First Time Assembly (OFTA) at the massive Bellwood Quarry site with help from Robbins personnel. “The guys built everything per the specs to help with scheduling. It was a challenge but there was no negativity during the process,” said Weslowski. Despite summer temperatures hitting 43 degrees Celsius (110 degrees Fahrenheit) and 100 percent humidity, the TBM was ready to launch by October 2016.

The robust TBM was assembled using Onsite First Time Assembly (OFTA) at the massive Bellwood Quarry site with help from Robbins personnel. “The guys built everything per the specs to help with scheduling. It was a challenge but there was no negativity during the process,” said Weslowski. Despite summer temperatures hitting 43 degrees Celsius (110 degrees Fahrenheit) and 100 percent humidity, the TBM was ready to launch by October 2016. Other challenges included groundwater encountered during tunneling. “We did encounter groundwater contamination that required remediation. This remediation work was completed successfully,” said Huie.

Other challenges included groundwater encountered during tunneling. “We did encounter groundwater contamination that required remediation. This remediation work was completed successfully,” said Huie. Client: Southwest Suburban Sewer District

Client: Southwest Suburban Sewer District Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP.

Task: After a recent emergency repair the Southwest Suburban Sewer District decided to upgrade the existing primarily ductile iron line. The project was located at Shorewood Dr. SW corner SW 125th and runs down the hill to pump station 7, which is located between two houses next to the bay. The section to be rehabilitated was 262 linear feet long and encloses multiple vertical bends of up to 22 degrees with a maximum operating pressure of 60 psi. Since the pipe runs on a steep hill and through people’s gardens in a residential area, a traditional open trench solution was not reasonable. Therefore, the sewer district had to choose between two trenchless technologies: Primus Line® and CIPP. On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

On September 18, 2018, a Robbins mega-sized slurry machine, measuring 13.7 m (44.8 ft) in diameter, made its first cut into hard rock. The epic launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM in Japan for the Hiroshima Expressway Line 5 project. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV. Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite measuring just 30 m (100 ft) wide x 60 m (200 ft) long. The 2,400 metric ton (2,650 US ton) machine will bore 1.4 km (0.9 mi) of the 1.8 km (1.1 mi) long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima. The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. “There is a lot of hard rock in Hiroshima,” said Mr. Akai, “and Robbins has a lot of experience boring hard rock.” The machine is expected to encounter granite with rock strengths up to 130 MPa (19,000 psi) UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future. “The development of this TBM is a milestone,” said Mr. Kiyomi Sasaki, General Manager of Robbins Japan, “it will lead to new tunnel applications worldwide.”