Uncategorized

Phoenix, Arizona – September 2, 2014 – NPL Construction Co. (NPL), a wholly–owned  subsidiary of Southwest Gas Corporation (Southwest), has entered into agreements to acquire the Link-Line Group of Companies (Link-Line) which includes Link-Line Contractors Ltd., W.S. Nicholls Construction Inc., W.S. Nicholls Industries Inc., and a fifty percent equity interest in W.S. Nicholls Western Construction Ltd., all Canadian-based construction companies. In a related transaction, affiliates of Southwest have reached an agreement to acquire certain assets and liabilities of Brigadier Pipelines Inc., a US-based affiliate of Link-Line. Link-Line’s current owners will retain a small ownership percentage in the combined businesses. The transactions are expected to close in October 2014.

subsidiary of Southwest Gas Corporation (Southwest), has entered into agreements to acquire the Link-Line Group of Companies (Link-Line) which includes Link-Line Contractors Ltd., W.S. Nicholls Construction Inc., W.S. Nicholls Industries Inc., and a fifty percent equity interest in W.S. Nicholls Western Construction Ltd., all Canadian-based construction companies. In a related transaction, affiliates of Southwest have reached an agreement to acquire certain assets and liabilities of Brigadier Pipelines Inc., a US-based affiliate of Link-Line. Link-Line’s current owners will retain a small ownership percentage in the combined businesses. The transactions are expected to close in October 2014.

The combination of NPL and Link-Line will create one of the largest natural gas distribution contractors in North America. The companies will be well-positioned to continue serving their existing customers, while establishing a sustainable path for continued growth both in the US and Canada.

Commenting on the pending transactions, NPL President and CEO Jim Kane said, “These pending acquisitions are an exciting part of our overall growth strategy, and Link-Line is a great strategic fit; culturally, the companies share NPL’s focus on safety, quality and customer satisfaction.” The acquisitions will result in no geographic or customer overlap. Emphasizing that the businesses will operate independently from NPL following the close, Mr. Kane confirmed, “We are not combining workforces; the same offices and the same people will be serving the same customers as they are today.”

Rick Delaney, President and COO of Link-Line, echoed those sentiments, saying, “NPL and the Link-Line family are aligned in both their customer relationship philosophy and unwavering dedication to safety and quality. We are excited to become part of NPL’s strategic growth and look forward to the future as part of this well-respected industry leader.”

Link-Line Contractors Ltd. is a natural gas services contractor providing construction and maintenance services for the Canadian utility industry, with operations in Ontario, Canada. The W.S. Nicholls companies, with operations in British Columbia and Ontario, Canada, provide industrial construction solutions, fabrication, and civil services to the oil and gas, pulp and paper, and automotive industries, as well as government and private sector customers. Brigadier Pipelines Inc. is a specialty midstream pipeline contractor, with operations in Pennsylvania. Link-Line and Brigadier include a combined workforce of over 1,100 employees.

NPL is an industry leader in utility infrastructure construction, specializing in natural gas and electric distribution across the United States. Founded in 1967, NPL has grown to a workforce in excess of 4,000 employees in more than 20 states from coast to coast. For more information, visit www.GoNPL.com.

Uncategorized

Ensuring Safe Drinking Water offers 21 case studies and in-depth analysis of delivering safe water to consumers

(DENVER) – The American Water Works Association has announced the release of its newest publication, Ensuring Safe Drinking Water: Learning From Frontline Experience With Contamination by Steve E. Hrudey and Elizabeth J. Hrudey.

It is easy for consumers to take safe drinking water for granted until something in the process goes wrong. With that in mind, Ensuring Safe Drinking Water by Steve E. Hrudey and Elizabeth J. Hrudey explores such challenging situations as waterborne disease outbreaks, chemical contaminations and “close calls” that can occur at water utilities. These situations are explored in-depth in 21 case studies that illustrate the immense responsibility that is placed on individuals who deliver safe drinking water to the public.

Written from the viewpoint of the personnel who were in the forefront of the situation, each case study recounted in Ensuring Safe Drinking Water is fully detailed with information on background, operational details and lessons learned included.

Ensuring Safe Drinking Water: Learning From Frontline Experience With Contamination is available in AWWA’s online store.

About the authors:

Dr. Steve E. Hrudey, a professional engineer and retired professor, has maintained a diverse career in the environmental health sciences and risk management for more than 40 years and has been recognized with several awards including a Queen Elizabeth II Diamond Jubilee Medal; the 2013 Research Excellence Summit Award of the Association of Professional Engineers and Geoscientists of Alberta; and the 2012 A.P. Black Award of the AWWA. He has participated in writing more than 25 expert panel reports, serving as Chair for 8, focused on issues such as the Walkerton Inquiry, safe drinking water for First Nations, environmental and health impacts of Canada’s oil sands industry and risk governance for water utilities.

Elizabeth J. Hrudey was trained and worked as a microbiology technologist at the Alberta University Provincial Laboratory of Public Health. She has worked as a researcher on off-flavor studies at the University of Alberta and engaged in various environmental health risk studies with Steve E. Hrudey & Associates Ltd. She was co-author for the widely recognized, best-selling book, Safe Drinking Water: Lessons From Recent Outbreaks in Affluent Nations, as well as for several papers and book chapters on the subject of safe drinking water.

About the publication:

Ensuring Safe Drinking Water: Learning From Frontline Experience With Contamination

By Steve E. Hrudey and Elizabeth J. Hrudey

Published by American Water Works Association

ISBN: 978-1-58321-924-9

Softcover, 296pp.

Price: $48 AWWA members, $62 non-members

Product #: 20752

# # #

Established in 1881, the American Water Works Association is the largest nonprofit, scientific and educational association dedicated to managing and treating water, the world’s most important resource. With approximately 50,000 members, AWWA provides solutions to improve public health, protect the environment, strengthen the economy and enhance our quality of life.

Uncategorized

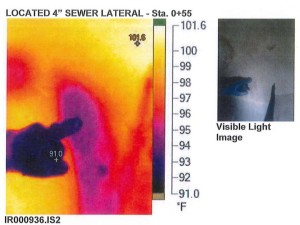

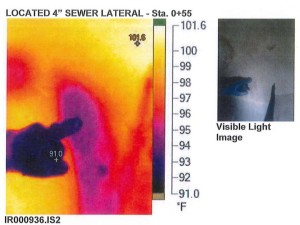

The City of Sarasota, Florida recently contracted with Miller Pipeline to line approximately 1500lf of 30” sewer mainline using CIPP liner. The liner was 15mm in thickness. With that thickness liner the “dimples” that are usually visible to delineate the service laterals when using thinner liners were not very noticeable if even visible at all.

Knowing that the CIPP process is all temperature based, it was decided to use our City owned thermography gun to see if it would pick up the difference in temperatures between the liner and where the laterals were located. The contractor had a second man go in the pipe to scan the pipe surface. The thermography worked perfectly and greatly reduced the amount of time it took the contractor to locate the laterals.

Uncategorized

GHD and Conestoga‐Rovers & Associates (CRA) have joined together to create a global leader in engineering, environmental consulting, architecture, and project management services. The result is a company that is more than 8500 strong, with 4000 in North America alone. The merger includes all of CRA and its family of companies, including Inspec-Sol and eSolutions. The companies have officially merged, with all ongoing employee shareholders in CRA becoming shareholders of GHD. This unique feature of the merger makes it one of the largest private stock transactions in the engineering and environmental consulting industry.

Ian Shepherd, GHD’s CEO, says, “This is one of the largest true mergers to have occurred in our industry. We are building on the strengths of two leading companies to create a global team of more than 8500 people across five continents. We are adding significant growth and scale to our business, while retaining the advantages of our private, employee-ownership business model for creating client value.”

Ed Roberts, CRA’s President, says, “CRA’s goal has been to leverage our outstanding environmental, geotechnical and forensic engineering capabilities and broaden our business in the municipal infrastructure markets. With GHD we’re able to do this, while expanding our global footprint, particularly in Australia and Asia, to better serve our multinational clients.”

By combining resources, melding business practices and pooling equity interests, the two companies become mutually dependent on each other for the creation of value over time. CRA and GHD will do this together by leveraging a deeper and more diverse talent pool, across a stronger geographic footprint.

Richard Wankmuller, GHD’s General Manager – Americas comments, “Our emphasis will be to integrate these two great companies while ensuring we maintain the responsiveness and service levels our clients expect from us. Our merger continues our growth trajectory in North America and around the world. With our combined business we now operate across a network of 200+ offices with 130 located in North America.”

The two companies will work together on a progressive integration program while focusing on continuity of service and maintaining a high level of responsiveness to clients. The combined business will be known as GHD.

Learn more on the GHD website.

Uncategorized

A specialized Robbins EPB broke through to fanfare on June 11, 2014, marking the completion of twin tunnels at San Francisco’s Central Subway in California, USA. The first of the two machines holed through on June 2, with both Robbins machines achieving swift advance rates of up to 40 m (131 ft) in 24 hours and 513 m (1,683 ft) in one month. The Central Subway is the second phase of the San Francisco Municipal Transportation Agency’s (SFMTA) Third Street Light Rail Transit Project.

Two 2.5 km (1.5 mi) long tunnels were excavated through ground ranging from soft soils to thinly bedded siltstone, shale and sandstone bedrock, as well as concrete diaphragm walls. The TBMs, operated by the Barnard/Impregilo/Healy (BIH) JV, were designed with a number of features to efficiently navigate the varied geology, steep grades and turns along the alignment, and to bore in what was rated as “Potentially Gassy with Special Conditions” by Cal/OSHA. A mixed face cutterhead was selected and designed to excavate the anticipated wide variety of ground, while active articulation was integrated between the TBM shields to lessen the risks of segment damage, ring deformation, and settlement during boring through curves. Robbins continuous conveyors offered efficient muck removal throughout tunneling.

Content via The Robbins Company. To read more about this project, visit The Robbins Company website.

Uncategorized

Fort Collins Utilities was faced with the need to rehabilitate two critical water supply pipelines.  One was a 24-inch concrete transmission main that followed a very serpentine alignment along the Poudre Canyon north and west of Fort Collins. The concrete raw water line was built in the 1920s and is in excellent structural condition but has had a history of leaking joints due to pipe movement. The pipe is located in mountainous terrain, which makes access very difficult for repair. The other pipeline is a 27-inch steel finished water main. In contrast to the line in the Poudre Canyon, the steel line is a straight alignment and lies in the backyards of homes with very limited access. It has suffered from corrosion related leaks.

One was a 24-inch concrete transmission main that followed a very serpentine alignment along the Poudre Canyon north and west of Fort Collins. The concrete raw water line was built in the 1920s and is in excellent structural condition but has had a history of leaking joints due to pipe movement. The pipe is located in mountainous terrain, which makes access very difficult for repair. The other pipeline is a 27-inch steel finished water main. In contrast to the line in the Poudre Canyon, the steel line is a straight alignment and lies in the backyards of homes with very limited access. It has suffered from corrosion related leaks.

Stantec evaluated numerous rehabilitation or replacement solutions and selected Swagelining as the preferred rehabilitation methodology. The Poudre Canyon project lined 1,500 feet of concrete pipe. The steel pipeline project rehabilitated 2,600 feet of pipe and was lined in a one day pull. It was the longest 27-inch pull done in the United States for the liner subcontractor at the date of this writing.

Both projects were successfully completed and are now in service. The differences in the construction experiences between these two projects, however, were substantial. This paper will illustrate the lessons learned in the design and construction process through a compare and contrast analysis of the projects and outline the City’s plan to complete the rehabilitation of the 24-inch waterline.

The City of Fort Collins Utilities had identified two waterlines in need of rehabilitation or replacement. One pipeline carries raw water to the Water Treatment Facility (WTF) and follows a serpentine alignment along the Poudre Canyon (Poudre Canyon Waterline). The other pipeline carries finished water to the Foothills pressure zone in the northwest portion of the Utility’s service area and is the only feed to a water storage reservoir (Foothills Water Transmission Line). These are two critical waterlines representing two drastically different situations.

To read more about this project download the full paper written by Ken Matthews, P.E. Stantec Consulting, Fort Collins, Colorado and Owen Randall, P.E. City of Fort Collins, Fort Collins, Colorado.

subsidiary of Southwest Gas Corporation (Southwest), has entered into agreements to acquire the Link-Line Group of Companies (Link-Line) which includes Link-Line Contractors Ltd., W.S. Nicholls Construction Inc., W.S. Nicholls Industries Inc., and a fifty percent equity interest in W.S. Nicholls Western Construction Ltd., all Canadian-based construction companies. In a related transaction, affiliates of Southwest have reached an agreement to acquire certain assets and liabilities of Brigadier Pipelines Inc., a US-based affiliate of Link-Line. Link-Line’s current owners will retain a small ownership percentage in the combined businesses. The transactions are expected to close in October 2014.

subsidiary of Southwest Gas Corporation (Southwest), has entered into agreements to acquire the Link-Line Group of Companies (Link-Line) which includes Link-Line Contractors Ltd., W.S. Nicholls Construction Inc., W.S. Nicholls Industries Inc., and a fifty percent equity interest in W.S. Nicholls Western Construction Ltd., all Canadian-based construction companies. In a related transaction, affiliates of Southwest have reached an agreement to acquire certain assets and liabilities of Brigadier Pipelines Inc., a US-based affiliate of Link-Line. Link-Line’s current owners will retain a small ownership percentage in the combined businesses. The transactions are expected to close in October 2014.