Uncategorized

Important Updates Alter Sewer Main Condition Assessment and Recommends New Standards for Accepting Post-Rehabilitation Projects

Sacramento, Calif. – January 11, 2016 – a leading provider of smart water leak detection  technologies and cloud computing applications, announced that its patented technology has been prominently featured in a new edition of the industry’s leading wastewater collection manual – OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS, VOLUME 1, SEVENTH EDITION.

technologies and cloud computing applications, announced that its patented technology has been prominently featured in a new edition of the industry’s leading wastewater collection manual – OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS, VOLUME 1, SEVENTH EDITION.

First published in 1976 with nearly 90,000 copies in print, the OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS manual is used by operators, managers, and consulting engineers, worldwide.

The Seventh Edition was published in December 2015, while the Sixth Edition was published in 2003.

“Our manual was originally designed to allow for self-paced instruction where operators worked at their own speed,” said Ken Kerri, Ph.D., P.E., former Director of the Office of Water Programs, California State University, Sacramento (1965-1997) and Chief Project Consultant until his passing in 2014.

“Once operators started using the manual for home study, we realized that it could serve as a textbook in the classroom,” said Dr. Kerri, who co-authored the section on Electro Scanning Inspection.

Today, the Office of Water Programs is a nonprofit organization operated by University Enterprises, Inc., California State University, providing distance learning programs for the operation and maintenance of drinking water and wastewater facilities.

“We are delighted to see our technology become an integral part of Chapter 4: Inspecting and Testing Collection Systems,” states Chuck Hansen, Chairman, Electro Scan.

Electro Scan’s technology is not only explained in Section 4.4 of the Seventh Edition, but also depicted in numerous illustrations, statistical analyses, and practical applications, in accordance with ASTM F2550-13.

In numerous instances, Electro Scan’s low voltage technology is able to identify and quantify leakage amounts in gallons per minute (GPM), often where defects are not identified by certified closed-circuit television (CCTV) operators or by using other inspection techniques.

Electro Scanning Inspection also provides wet-weather condition assessment information, not available using CCTV inspection, and can be performed year around to help locate sources of sanitary sewer overflows (SSOs) and find defects in newly repaired or relined pipes.

Important updates contained in the Seventh Edition suggest altering the acceptance criteria for rehabilitated pipes using Electro Scanning Inspection to assess the effectiveness of cured-in-place pipe (CIPP), service re-connections, and point repairs, explaining the importance of quantifying pre- and post-rehabilitation inspection results.

Given Electro Scan’s ability to automatically find sources of leaks that are frequently missed by CCTV inspection, the manual suggests using Electro Scanning Inspection first to objectively locate and quantify pipe defects, then using CCTV inspection to document the most severe defects.

In addition to Electro Scanning Inspection (Section 4.4), Chapter 4: Inspecting and Testing Collection Systems also includes an updated section on CCTV Inspection (Section 4.3), Smoke Testing (Section 4.5), and Dye Testing (Section 4.6).

Continues Hansen, former Founder and CEO of Hansen Information Technologies, “It was an honor to contribute to Electro Scanning Inspection at the invitation of Dr. Kerri and share this game-changing technology with operators, managers, consulting engineers, and students.”

Image 1- Mark Grabowski,Vice President and General Manager, Electro Scan Inc. and Dr. Kerri, co-author of Electro Scanning Inspection and former Chief Project Consultant, Office of Water Programs until his passing in 2014.

Image 2- Sixth Edition, Volume 1,

published in 2003.

About Electro Scan

Founded in 2011, Electro Scan develops smart water leak detection instrumentation and cloud computing applications that automatically locate, measure, and report pipe condition assessments for water, sewer, and gas pipelines. The Company is headquartered in Sacramento, California.

Contact

Carissa Boudwin, Tel: +1 916 779 0660, Email: carissa@electroscan.com

Uncategorized

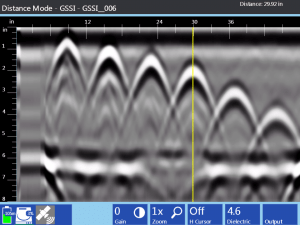

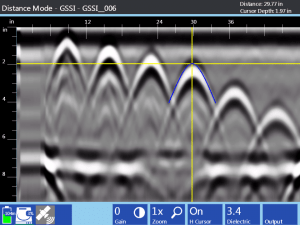

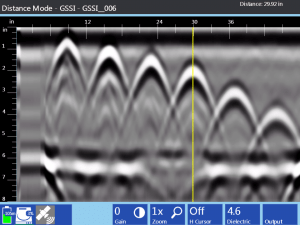

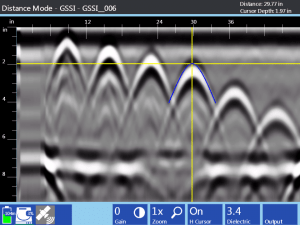

GSSI announces the release of updates to the SIR® 4000 ground penetrating radar (GPR)  control unit. The controller is designed to bridge the legacy of GSSI’s traditional analog antennas with next-generation of digital offerings, giving it the flexibility by supporting a wide range of users in numerous applications. The updates bring the StructureScan 2D collection module to the controller, simplifying its use for the concrete construction industry.

control unit. The controller is designed to bridge the legacy of GSSI’s traditional analog antennas with next-generation of digital offerings, giving it the flexibility by supporting a wide range of users in numerous applications. The updates bring the StructureScan 2D collection module to the controller, simplifying its use for the concrete construction industry.

The StructureScan 2D collection module offers users greater flexibility for using the controller in concrete construction industry applications. The module includes high frequency antenna-specific set-ups to ensure survey efficiency, and enables the controller to automatically recognize smart antenna set-ups.

Additionally, the update offers users the option of on-the-fly automatic gain to better enhance the data display, while still saving the file in the original raw format for post processing. The updated collection module also includes a horizontal zoom function, allowing users to increase the size of the data set up to 8x to resolve smaller targets, and a “Save Image” shortcut for quick reports.

Fully integrated, the SIR 4000 provides a 10.4 inch high definition LED display, a simple user interface, plug-and-play GPS integration, and Wi-Fi enabled data transfer functionality.The SIR 4000 is designed with a number of exclusive features, including a casted aluminum chassis that offers superior temperature stability and an impact resistant design that combined, delivers a full IP 65 rated- able to withstand tough jobsite conditions.

For pricing and availability, please contact your local sales representative.

About GSSI:

Geophysical Survey Systems, Inc. is the world leader in the development, manufacture, and sale of ground penetrating radar (GPR) equipment, primarily for the concrete inspection, utility mapping and locating, road and bridge deck evaluation, geophysics, and archaeology markets. Our equipment is used all over the world to explore the subsurface of the earth and to inspect infrastructure systems non-destructively. GSSI created the first commercial GPR system nearly 45 years ago and continues to provide the widest range and highest quality GPR equipment available today.

Uncategorized

BOSTON – EPA is now accepting nominations for the 2016 Environmental Merit Awards, which will recognize environmental achievements during the past year. Award categories are available for individuals, businesses, governmental entities, and other organizations. Awards are also given under a lifetime achievement category.

These regional awards have been given out annually since EPA was created in 1970. Past recipients have included scientists, community activists, business representatives, public officials and other individuals committed to preserving the environment. An independent EPA panel will select the winners based on the following criteria: long-term effects on the environment; ability to address an environmental problem or need; collaboration with others; ability of the program or accomplishments to be widely shared; clarity and effectiveness of the presentation; and promotion of innovative ideas or techniques. Awards are traditionally given in four categories: individual; business, industry, trade, and professional organization; local, state or federal government; and environmental, community or non-profit organization.

This year EPA will also be awarding the Children’s Environmental Health Award for an Individual or group that has made significant progress, contribution, leadership toward protecting children from environmental health risks in schools, homes, and childcare environments in New England. Criteria for the Children’s Environmental Health Awards are:

– Innovative efforts to increase awareness of children’s unique vulnerabilities to pollutants and other environmental hazards through research, education, outreach, or capacity-building activities; and/or

– Development of activities or programs that have produced tangible reductions in risk to children from environmental health hazards where they live, learn, and play.

A final award category is available. For a third year EPA will be awarding the Ira Leighton “In Service to States” Environmental Merit Award. This award recognizes an individual or organization that has made significant strides in facilitating state and federal partnerships through innovative sustainable solutions addressing critical environmental challenges in New England. The successful candidate will have actively demonstrated conviction and leadership in protecting the environment and in promoting sustainable practices, and will be determined by a collaborations among the New England Interstate Water Pollution Control Commission (NEIWPCC), the Northeast States for Coordinated Air Use Management (NESCAUM), the Northeast Waste Management Officials’ Association (NEWMOA), in coordination with the New England state Environmental Commissioners.

The deadline for nominations is February 12, 2016. Awards winners will be invited to a ceremony in May in Boston. Nominations are only accepted online.

More information on Award categories, evaluation criteria and how to submit nominations: http://www.epa.gov/environmental-merit-awards-new-england

Uncategorized

Planting 80,000 trees is equivalent to reforesting over 250 football fields.

Bala Cynwyd, PA, December 10, 2015 – Philadelphia Insurance Companies (PHLY) will support the planting of 80,000 trees after reaching the goal of a yearlong collaboration that engaged agents, customers, and employees. The goal of the PHLY 80K Trees initiative, which launched in partnership with the Arbor Day Foundation on Earth Day 2015, was to help wildfire and natural disaster recovery efforts and restore habitats across the country. There are over one million acres in desperate need of replanting due to natural disasters according to the U.S. Forest Service. PHLY’s efforts to plant 80,000 trees will help provide greater security to communities, including PHLY’s policyholders.

“PHLY is on a mission to save forests devastated by natural disasters,” shared Bob O’Leary, president and chief executive officer of Philadelphia Insurance Companies. “Trees provide habitat for wildlife and clean water for communities, while helping to protect businesses from flooding by increasing soil stability and reducing storm water runoff in urban areas.”

Being a property/casualty carrier and providing flood insurance, PHLY recognizes the potential effect these risks might have on the marketplace. To protect communities from future devastation, PHLY has taken action through PHLY 80K Trees to address the imperative need to build healthy forests and ecosystems.

The PHLY 80K Trees goal was reached with the help of PHLY’s independent agents, brokers, and policyholders. PHLY invited producers and policyholders to enroll into receiving paperless statements. The company will use the cost savings to fund the planting of 40,000 trees in Bastrop State Park and surrounding communities. An additional 20,000 trees will be planted in both Superior National Forest in Minnesota and Modoc National Forest in California. PHLY employees also raised money to support the initiative and will help plant a portion of the 40,000 trees in Bastrop State Park near Austin, TX in January 2016.

As part of its partnership with the Arbor Day Foundation in 2015, PHLY also purchased carbon-offsets, which reduced its carbon footprint by 2,200 metric tons. This is equivalent to removing 463 passenger vehicles from the road for a year.

For more information about the initiative please visit www.PHLY.com/Trees.

About Philadelphia Insurance

Philadelphia Insurance Companies designs, markets, and underwrites commercial property/casualty and professional liability insurance products incorporating value added coverages and services for select industries. In operation since 1962, the Company, whose commercial lines insurance subsidiaries are rated ’A++’ (Superior) by A.M. Best Company and ’A+’ for counterparty credit and financial strength by Standard & Poor’s, is nationally recognized as a member of Ward’s Top 50, National Underwriter’s Top 100, and one of the Top 150 Workplaces in America. Policies are underwritten by Philadelphia Indemnity Insurance Company. The organization has 50 offices strategically located across the United States to provide superior service. For more information, please visit www.PHLY.com.

About Arbor Day Foundation

Arbor Day Foundation is a million member nonprofit conservation and education organization with the mission to inspire people to plant, nurture and celebrate trees. More information is available at arborday.org.

Uncategorized

AURORA, IL-TT Technologies recently launched its new comprehensive trenchless website. The fully responsive design allows users to view and interact with the website from mobile devices including tablets and smartphones. Trenchless contractors and engineers are able to get information on trenchless tools, methods and parts and accessories on their mobile device directly from the jobsite.

AURORA, IL-TT Technologies recently launched its new comprehensive trenchless website. The fully responsive design allows users to view and interact with the website from mobile devices including tablets and smartphones. Trenchless contractors and engineers are able to get information on trenchless tools, methods and parts and accessories on their mobile device directly from the jobsite.

The site contains photographs, illustrations and animations of trenchless methods and applications including pipe bursting, pipe ramming, horizontal boring, lateral replacement and directional drilling.

The site is designed to be an extensive trenchless pipe replacement resource for contractors, engineers and municipalities. In addition to method descriptions and equipment specifications, the site contains numerous case studies describing actual trenchless projects.

The site can be accessed at: www.tttechnologies.com

Uncategorized

Aegion Corporation Announces Several Actions to Enhance Future Growth

St. Louis, MO – January 4, 2016 – Aegion Corporation (Nasdaq Global Select Market: AEGN) today announced several actions to deliver sustainable growth and address the market realities in the North American energy markets.

Charles R. Gordon, Aegion’s President and Chief Executive Officer, said, “In today’s challenging business environment, we are continually evaluating our exposure to the end markets we serve. To that end, we announced an investment in our capabilities to rehabilitate pressure pipelines for water and wastewater applications by acquiring Underground Solutions, Inc., an established provider of a patented fusible PVC technology, and to improve Fyfe’s global reach by acquiring the remaining international rights from Fyfe Group, LLC. In addition, we are divesting our equity stake in Corrosion Protection’s Canadian pipe coating joint venture, downsizing Energy Services’ operations in Central California’s upstream market and implementing a plan to reduce annual operating expenses across Aegion.”

Aegion’s Infrastructure Solutions platform adds to its capabilities

Aegion has executed a definitive agreement to acquire Underground Solutions, Inc. for $85 million in cash and expects to close the transaction during the first quarter of 2016. The Company will separately pay for the discounted value of tax benefits (estimated today to be approximately $5 million) associated with Underground Solutions’ net operating loss carry forwards at closing. Aegion will fund a substantial portion of the purchase price with existing cash and the remainder from borrowings against the Company’s line of credit. Aegion expects the transaction to be accretive to 2016 GAAP earnings per share with revenues of approximately $50 million and operating margins in excess of 10 percent. Several key members of Underground Solutions’ senior management, who average more than 20 years of industry experience, will join Aegion to form an expanded team dedicated to trenchless rehabilitation of existing pressure pipelines.

Underground Solutions’ patented fusible polyvinyl chloride (“PVC”) products focus on the rehabilitation of pressure pipelines, primarily in North America. Underground Solutions uniquely complements Infrastructure Solutions’ existing pressure pipe rehabilitation technologies InsituMain®, InsituGuard® and Tyfo®/Fibrwrap® and increases Aegion’s presence in the pressure pipe market to nearly $90 million in annual revenues.

“We are pleased to have Underground Solutions join Aegion,” Mr. Gordon commented. “Our market research suggests assembling a portfolio of technologies is the right strategy to establish a leading position in the North American pressure pipe rehabilitation market. We believe the combination of Underground Solutions’ patented PVC technologies with our Insituform® and Tyfo®/Fibrwrap® technologies will allow us to strengthen our position in this attractive market by offering our customers a broader portfolio of solutions.”

Aegion’s 2016 outlook

“As we look to 2016, Infrastructure Solutions remains focused on maintaining its leadership position by taking advantage of continuing favorable market conditions in North America,” stated Mr. Gordon. “In addition, the acquisition of Underground Solutions is an important step to advance our stated strategic objective to expand our presence in the growing pressure pipe rehabilitation market in North America.

“In contrast, we expect 2016 will be a more difficult year for the North American energy markets, particularly related to upstream capital spending as customers continue to decrease investments in response to persistent low oil prices. Based on the decision to reduce our exposure in the upstream markets, we expect Energy Services’ revenues to decline by approximately $70 million from 2015 with no adverse impact to its operating margins percentage as a result of the restructuring. Our Corrosion Protection platform is likely to experience reduced upstream market activity that will negatively impact profitability, especially for the Bayou Louisiana coating facility during the first half of 2016. The planned cost savings from the announced restructuring initiatives and favorable North American midstream and downstream markets are expected to offset the market challenges affecting Energy Services and Corrosion Protection.

“The favorable market conditions for the majority of Aegion’s business and the strategic actions outlined today give us the opportunity for 2016 non-GAAP earnings per share to be in line with what we expect to achieve in 2015. This outlook excludes a significant contribution from the Shell Appomattox contract we believe is likely in the fourth quarter of 2016. However, the exact schedule for the start of pipe coating activities has yet to be set. Longer-term, we believe our diversified portfolio of technologies and services will deliver sustainable growth as we have repositioned our upstream oil exposure to reflect current market realities. The broader strategic initiatives we previously outlined should enhance growth by accessing new markets to rehabilitate water pressure pipelines, enable more effective pipeline asset integrity management in the growing midstream market and offer higher-margin services through strong customer relationships in the West Coast downstream refining market.”

About Aegion

Aegion Corporation is a global leader in infrastructure protection and maintenance, providing proprietary technologies and services: (i) to protect against the corrosion of industrial pipelines; (ii) to rehabilitate and strengthen water, wastewater, energy and mining piping systems and buildings, bridges, tunnels and waterfront structures; and (iii) to utilize integrated professional services in engineering, procurement, construction, maintenance and turnaround services for a broad range of energy related industries. Aegion’s business activities include manufacturing, distribution, maintenance, construction, installation, coating and insulation, cathodic protection, research and development and licensing. More information about Aegion can be found on our internet site at www.aegion.com.

About Underground Solutions, Inc.

Underground Solutions, Inc. is a leader in water and wastewater infrastructure and process technologies by providinginfrastructure technologies for water, sewer and conduit applications. Underground Solutions, Inc. Fusible PVC® products include, Fusible C-900®, Fusible C-905® and FPVC®, which contain a proprietary PVC formulation that, when combined with its patented fusion process, results in a monolithic, fully-restrained, gasket-free, leak-free piping system. Fusible C-900® and Fusible C-905® both comply with the AWWA standards AWWA C900 and C905, respectively and are certified to NSF 61. More information about Underground Solutions, Inc. can be found at www.undergroundsolutions.com.

Uncategorized

(12/23/15) EPA is seeking public comment on a proposed agreement to allow the Massachusetts Army National Guard to train with a “Percussion Activated Neutralizer” at the Camp Edwards portion of Joint Base Cape Cod.

The comment period, which runs through Jan. 21, 2016, provides an opportunity for public input on this modification to EPA’s 1997 Safe Drinking Water Act Administrative Order. This authorization process is part of EPA’s regulatory role at the Massachusetts Military Reservation to protect the sole source Cape Cod Aquifer.

In a letter dated August 18, 2015, the Massachusetts Army National Guard requested EPA approval to use Percussion Activated Neutralizers (PAN) for training purposes at Camp Edwards. The letter, which included information on the chemical makeup of the device and a description of its intended use, is available on EPA’s website. EPA does not expect that the chemical makeup and use of the items, in the manner proposed, will present a threat to the aquifer, and is now seeking public input on this proposal.

Since 1997, EPA has issued administrative orders at the base, three which fall under the Safe Drinking Water Act. Among other provisions one of the administrative orders includes the suspension of particular military training activities at the Training Range and Impact area of Join Base Cape Cod, due to the nature of the potential contaminants within some of the training devices. However, included was a provision for modification if among other requirements there was, “documentation demonstrating that the use of a propellant… suspended pursuant to this Order does not present a threat of harm to the public or the environment that would warrant its continued suspension under this Order.”

The authorization to use this device is also conditional upon the Massachusetts Army National Guard’s compliance with all conditions established by the Environmental Management Commission.

More information: EPA’s response to the Massachusetts Army National Guard, including EPA’s proposed agreement to modify the Administrative Order to authorize use of the PAN in training, is at www.epa.gov/superfund/otis

Uncategorized

Contributed by Vermeer

A/C may be the secret to landing the best HDD operators

Creature comforts.

It’s a term with a specific meaning. But it also speaks to the various challenges the HDD market is facing.

Creature comforts are the features on a horizontal directional drill that help make operators more comfortable.

It’s an issue of rising importance in the HDD market, and the reason goes back to the challenges contractors are dealing with.

First and foremost is the shortage of skilled HDD operators. They are in high demand, and it can be hard to find them and, once hired, to retain them. So contractors want to keep them happy, and part of that is keeping them comfortable.

Also, a comfortable operator is a more productive operator. Productivity is more important than ever as deadlines and margins get tighter on HDD jobs.

“On some of the bigger bores, those guys are in the cabs for hours. They don’t come out of there,” says Mark Sonnenberg, operations manager for the Vermeer Great Plains dealership. “I think owners have figured out that if they can keep that operator on task, and if the operator likes to sit inside an air-conditioned cab, everyone is better served.”

Cabs have been at the forefront of the increased emphasis on creature comforts. Just a few years ago, Sonnenberg saw very few drills with climate-controlled cabs being sold. Now, about half of his dealership’s drill sales include them.

Another point of emphasis at Vermeer has been common control systems across different drills. That helps to reduce the learning curve for operators and allows them to be proficient on multiple machines, which touches on those labor and productivity concerns.

The controls also have become simpler to use and more ergonomic. Today an HDD operator can run a drill pretty much without taking his hands off the joysticks, which makes controlling the drill easier and also decreases repetitive motions.

Other creature comforts include improved displays, enhanced sightlines from the operator’s seat and quieter machines, which also benefit the general public. Creature comforts will continue to evolve, and Vermeer balances those features with designs that meet the space and power needs of contractors.

“We’re never satisfied,” says Jon Kuyers, Underground global product manager at Vermeer. “Comfort could always get better, and we try to meet those needs while maintaining the specifications that our customers care about.”

For more articles like this, visit: Vermeer Navigator Nation blog, an educational site for HDD operators.

Uncategorized

Cardno’s UAS and Remote Sensing Data Analytics staff will work closely with established Subsurface Utility Engineering (SUE) and Survey teams to provide cutting-edge technology anywhere in the U.S.

PORTLAND, ORE. (November 3, 2015) – Professional infrastructure and environmental services consultancy Cardno is excited to announce the addition of two new services in the U.S.: UAS and Remote Sensing Data Analytics.

UAS

Cardno has received a nationwide 333 exemption and Certificates of Waiver or Authorization (COA) issued by the Federal Aviation Administration for commercial UAS mapping operations at a 200 ft Above Ground Level (AGL) height in “undeveloped” areas. Cardno is committed to expanding its capabilities and technical expertise in the UAS market, as it is one of a few firms of its size licensed to operate in this emerging technology.

Cardno’s fleet of UAV includes both fixed wing and octocopter solutions, which carry mapping grade fixed focal length cameras, HD video, and infrared data/image collection capabilities. The UAV take high-resolution color imagery, producing digital terrain models and other high-tech mapping for a wide range of applications.

By adding UAS capabilities, Cardno strengthens its cutting-edge portfolio of geospatial, mapping, and survey services – including mobile GIS, large format photogrammetry surveys, remote sensing, mobile mapping LiDAR, underground utilities mapping, amongst others – and complements its information management services such as environmental data and compliance management, application and website development, business process modeling, decision support systems, and systems integration.

REMOTE SENSING DATA ANALYTICS

UAS technology is revolutionizing critical data capture, and Cardno’s Remote Sensing Data Analytics team has the flexibility to provide sensor and platform combinations that are cost-effective and meet client needs in a variety of industries and services: emergency response, mining, railway inspection, biological resources, oil & gas, utilities, refineries, water resources, and vegetation analysis.

Cardno’s Remote Sensing Data Analytics scientists have the expertise and experience to provide the highest-quality orthoimagery and point cloud data for developing base products for projects. These base products can then be further analyzed to create an extensive list of value-added products to aid clients in achieving their end goal while staying on schedule and budget.

Cardno’s Jason Kack, West Business Manager, stated, “Cardno has the largest fleet of subsurface utility vehicles in the U.S. and our SUE/survey team comprises over 450 professionals. Cardno also operates with a global network of around 8,100 staff in over 250 offices, giving us the resources to successfully deliver complex projects while leveraging local knowledge and relationships. We are excited to offer this diverse talent to our clients, along with UAS and Remote Sensing Data Analytics—two innovative and crucial next steps to support client projects.” View our website for more details.

Uncategorized

Robbins Machine is the first TBM to break through in Two Decades

A crowd of crew members gathered to celebrate in front of a newly emerged hard rock TBM on December 10, 2015 in northern Norway, but their celebration was about more than just a breakthrough. The 7.2 m (23.6 ft) diameter Robbins Main Beam machine had traversed incredibly hard rock, water inflows, and more to become the first TBM in the country to break through in over 20 years.

The 7.4 km (4.6 mi) long headrace tunnel for the RøssågaHydroelectric Project offered up a number of challenges to the crew. “We bored through hard, quartz-rich rock with rock strengths up to 300 MPa (43,500 psi) UCS and softer karstic limestone with water ingress,” explained Tobias Andersson, TBM Manager for contractor Leonhard Nilsen & Sønner(LNS). Despite the geological challenges, the TBM performed very well and achieved a record production of 250 m (820 ft) advance in one week, as well as a high of 54 m (177 ft) in one day. Advance rates consistently ranged from 180 to 200 m (590 to 660 ft) per week throughout the project.

The hard and abrasive rock required both fine-tuning of the disc cutters and a learning curve with regards to TBM operation. “We overcame the rock by adapting driving parameters to the different geology, cutter wear and vibrations of the machine. We had regular maintenance, but most important of all we got really good at changing the cutters, with times down to 10 minutes per cutter change, which couldn’t have been done without good team work,” said Andersson.

It was the many cutter changes that prompted the close-knit team of LNS and Robbins to look for a better solution. “Extremely hard rock (above 250 MPa/36,300 psi) will always be a great challenge for any cutter. The very special features of the rock encountered combined with the extreme hardness made us go back to the Robbins Cutter Department to develop special cutter rings for the project. These rings increased the cutter life significantly for the project and contributed to the good production,” said Sindre Log, General Manager of Robbins Norway.

The Robbins TBM was launched following Onsite First Time Assembly (OFTA) in January 2014, less than twelve months after contract signing, and was from the outset designed for hard rock conditions. A Measurement While Drilling (MWD) system was included to analyze the ground conditions ahead of the TBM, while probe drilling was done systematically throughout the project. “This is a strong and simple machine ready to tackle hard rock conditions, but also designed to handle softer rock, which allowed for fast excavation. We had good support from competent Robbins field service,” said Andersson.

After all the obstacles, it was clear that the breakthrough ceremony celebrated a triumph of teamwork as well as a new chapter for TBMs in Norway. “Our whole jobsite was gathered for the event: LNS management, representatives from Robbins, and our client Statkraft. People said it was the best breakthrough event they had seen,” said Andersson. Now that tunneling is complete, project owner Statkraft will work to commission the tunnel and fill it with water by spring 2016.

Image 1: The LNS and Robbins crew celebrate Norway’s first TBM breakthrough in 23 years at the RøssågaHydroelectric Project. Photo credit: LNS

Image 2:Kare Solhaug of Robbins Field Service stands proudly in front of the 7.2 m (23.6 ft) diameter TBM on the day of its breakthrough December 10, 2015. Photo credit: LNS

Image 3:The Robbins Main Beam machine was launched in January 2014 and overcame incredibly hard rock, water inflows, and more. Photo credit: Statkraft

technologies and cloud computing applications, announced that its patented technology has been prominently featured in a new edition of the industry’s leading wastewater collection manual – OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS, VOLUME 1, SEVENTH EDITION.

technologies and cloud computing applications, announced that its patented technology has been prominently featured in a new edition of the industry’s leading wastewater collection manual – OPERATION AND MAINTENANCE OF WASTEWATER COLLECTION SYSTEMS, VOLUME 1, SEVENTH EDITION.