Industry News, trenchless products

Project Profile:

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

During design the team discovered an old as-built drawing of a now abandoned 12″ diameter concrete pipe in the path of the tunnel at approximately 320LF out. A series of GBM pilot tubes were installed ahead of the 51″ diameter tunnel launch in an attempt to proof the drive and find this pipe. Two of the

four pilot tube drives were deflected in this area; indicating that something was out there. After lots of internal discussions the decision was made to carry on with the original design and attempt to tunnel through this questionable area at 320LF out. While carefully tunneling through this area, a large pocket of river rock was discovered, but no remnants of any concrete pipe were ever found. This was great news for the project team. The end result was a successfully installed 51″ casing under I-215 for Salt Lake City Public Utilities, allowing Whitaker Construction to continue on with their project as planned.

Photos: Morty the Tunnel Rat and two members of the BTrenchless Crew getting ready for an Akkerman MTBM launch.

trenchless people

Scott Rosenthal, Associate Professor and Department Head of Mining Engineering at Montana Tech

Scott Rosenthal, Associate Professor and Department Head of Mining Engineering at Montana Tech

How long have you been involved with underground infrastructure and trenchless technology? What brought you to the industry and/or your specialty area?

In my career as a mining engineer I was never directly involved with trenchless technology applications. After becoming a professor of mining engineering, I had a graduate student look at a novel directional drilling concept for open pit mining and as part of that project we looked at existing trenchless technologies. Prior to this project, I had always been fascinated by tunnel boring machines (moles) from the mining side and what they have accomplished in civil infrastructure construction and mining applications. We are re-introducing an underground construction course for our students which will include an exposure to tunnel boring machines.

You’ve had a successful career in mining, both in the field and as an educator. What drew you to mining and eventually to teaching?

What drew me to mining was a fascination with minerals that my father, a ceramic engineer, instilled in me. Where do you find the best minerals? In mines. Once I began studying mining engineering, I realized the industry had the biggest and coolest machines around and I was hooked. It was always on my bucket list to teach and after doing several guest lectures at a couple of universities, an opening arose at my Alma Mater, so I applied and was selected to join the team.

Share one project/objective you and your students are working on or recently worked on.

Placement of our students is not always in mining engineering roles and a number of our graduates accept positions with heavy civil contractors. Adding a knowledge of trenchless technology to their education through our underground construction course will add another tool to their tool belt. The project I am working on is building the underground construction course with the aid of industry contacts and attending an industry sponsored education forum for university professors this summer.

Why did you join NASTT? Are you planning on attending No-Dig 2020?

I joined NASTT because it is the industry organization focused on trenchless technology. It will help me build the relationships I need to be successful in educating our students going forward. As the faculty advisor for our NASTT student chapter, my membership demonstrates to the students my commitment to supporting them, the profession and NASTT. I do plan on attending No-Dig 2020 and hope to be able to bring a few students along as well.

Any upcoming travel/vacation plans? Traveling with family, friends?

Sonya, my wife, and I are very involved with the Rocky Mountain Elk Foundation here in Montana. Our big summer get away is to the annual Rocky Mountain Elk Foundation’s Elk Camp in Park City, Utah. The rest of the summer is committed to enjoying the brief Montana summer and continuing work on an historic preservation project that we have.

Anything special you like to do when you’re not working?

Back to the love of minerals and mining—I do underground tours at the World Museum of Mining here in Butte to help out the museum and to help educate the visitors about the past and present importance of mining; and, occasionally I get out into the mountains to look for minerals and spend a little time panning for gold in a favorite creek.

Book you are reading? Construction Vibrations by Charles H. Dowding is my current reading of choice for two reasons: 1. back to the development of our underground construction course, this text helps quantify why trenchless technology has applications for large civil projects versus traditional underground drill and blast; and, 2. I am working on a PhD that may involve research around underground vibrations in adjacent openings from nearby blasting.

Sports team? Green Bay Packers

Android or iPhone? iPhone because a millennial once joked if I owned one, I couldn’t figure it out (he was wrong).

Favorite App? Any banking pp that allows me to deposit checks—what a time saver!

Interested in joining NASTT? Click here for more info or contact Carolyn Hook for details.

Industry News, trenchless people, trenchless products

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the Vermeer Vac-Tron Series trailer vacs.

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the Vermeer Vac-Tron Series trailer vacs.

Project Challenge

The team at MacAllister Rental wanted to offer customers with an effective soft excavation method that would deliver outstanding productivity safely. They were familiar with vacuum excavators but wanted to find an equipment partner that manufactured quality machines that were easy to operate and efficient to run.

Solution

MacAllister Rental added Vac-Tron vacs to its fleet eight years ago. Since then, rental demand for these machines has increased significantly, and the rental store has continued to grow its fleet of Vac-Tron vacs. “We feel that CAT is the leader in the hydraulic excavator industry and the Vac-Tron series trailer vac is an industry leader in the vacuum excavator industry, so it fits very well with what we are trying to accomplish,” said Dan Hickman, district sales manager.

According to Chad Brogan, a sales representative with MacAllister Rental, most of their customers use Vac-Tron vacs for precise excavation when conventional excavation is not able to be used. “We have also found other uses for the Vac-Tron vacs with construction and foundation cleanup after heavy rains. It was a no brainer to add it to our fleet because we want to provide the best solutions for our customers,” he added.

Results

“Customers have commented that when they have these on their jobsites, they really have a vacuum, pressure washer, and an air compressor all built into one piece of equipment,” explained Hickman. “I can’t say it enough; contractors can be much more efficient using Vac-Tron vacs than other excavation methods when working around fiber optics, gas or water lines, as well as near foundations and wells. All that material gets sucked up into a self-contained unit, and they can dispose of it where they want to. Our customers get a cleaner jobsite, the job gets done faster with a lot fewer people, so it makes them money,” he concluded.

Learn more about Vac-Tron by visiting vactron.com.

Industry News, trenchless people

June, 2019 (Pella, IA) Ring-O-Matic is pleased to announce that Dave Langenfeld has joined the company as the Director of Engineering & Product Development. Dave comes to Ring-O-Matic with over 30 years of experience in the construction equipment industry at Vermeer Corp and most recently at Weiler. With a unique and experienced skill set in all aspects of engineering, Dave will provide fresh leadership to the engineering team and add significant value to the entire operation located in our Pella, Iowa location.

June, 2019 (Pella, IA) Ring-O-Matic is pleased to announce that Dave Langenfeld has joined the company as the Director of Engineering & Product Development. Dave comes to Ring-O-Matic with over 30 years of experience in the construction equipment industry at Vermeer Corp and most recently at Weiler. With a unique and experienced skill set in all aspects of engineering, Dave will provide fresh leadership to the engineering team and add significant value to the entire operation located in our Pella, Iowa location.

Dave has a proven record of not only leading new product develop, project timelines, efficiency improvements, and understands the changing climate of our industry, but most importantly has a proven ability to coach, mentor and drive for daily improvement across an organization

“Frankly I’m honored that someone with Dave’s experience, technical skills, and desire would entertain joining our Ring-O-Matic team.” stated Brian Metcalf CEO/Owner of Ring-O-Matic. “His background, experience and knowledge in product development within our industry is just not easy to come by, so we’re excited to have Dave’s leadership!” Metcalf said.

Ring-O-Matic is a leading provider of trailer and truck mounted vacuum excavation equipment and car wash pit cleaning machines. Founded in 1960, Ring-O-Matic products are known for their proven performance, innovation, reliability and built to last the rigors of job sites in the underground utility, municipal and water and gas markets. Headquartered in Pella IA, Ring-O-Matic employs a Sales, Engineering and Production team dedicated to building the industry’ s most productive vacuum excavation machines. Ring-O-Matic products are sold worldwide through independent equipment dealers.

Industry News, trenchless people

It is with deep sadness that The Robbins Company announces the passing of Richard James Robbins, President and CEO from 1958 to 1993. Dick passed away surrounded by family on Thursday May 30, 2019 in Seattle, Washington, USA. He is survived by his wife Bonnie, son Jim and daughter Jennifer.

It is with deep sadness that The Robbins Company announces the passing of Richard James Robbins, President and CEO from 1958 to 1993. Dick passed away surrounded by family on Thursday May 30, 2019 in Seattle, Washington, USA. He is survived by his wife Bonnie, son Jim and daughter Jennifer.

Dick Robbins was widely regarded as a titan of the tunneling industry and built The Robbins Company into an industry leader, from the first Double Shield machine to modern-day disc cutters for hard rock, to his notable TBM innovations at the Channel Tunnel connecting the U.K. and France. In total he filed 11 U.S. patents and 56 foreign patents in the field of underground mechanical excavation, and ultimately won the 2009 Benjamin Franklin Medal in Engineering for his contributions. He accomplished all of this after taking over the company at the age of 25 following the untimely passing of his father James S. Robbins in a plane crash.

“In 1968 when I first had the chance to work for what was then known as James S. Robbins Co., I did not fully appreciate that I was getting a chance to work with the greatest innovator in the tunneling industry,” said Robbins President Lok Home. “Dick was a great mentor as a boss and as a person. He was always pushing the limits of what could be done with TBMs. Dick’s integrity, energy, and passion improved the worldwide tunneling industry, and his creations set many of the industry standards. It has been an honor to further the great name of Robbins in the industry.”

“Dick unselfishly gave back to his industry and to his community,” said consultant and former ITA President Harvey Parker, a long-time friend of the Robbins family. “He was very active in our industry’s professional associations both here in the United States and internationally. I was honored to work closely with Dick during his significant involvement in the International Tunnelling and Underground Space Association (ITA) where he served on the Executive Council for years, was elected First Vice President, and was a leader for the ITA Working Group on Mechanized Tunnelling.” Dick’s many awards garnered over the years included numerous honorary degrees, memberships and directorships in a wide variety of organizations ranging from Virginia Mason Medical Center to the Board of Trustees at his alma mater Michigan Technological University. In 1999, the Engineering News-Record selected him as one of the “125 Top People of the Past 125 Years,” an equipment innovator who “helped shape this nation and the world.”

He was well-known in Seattle for his active contributions in community organizations and sports. “Dick was a wonderful family man,” said Parker. “He was a great personal and professional friend who was always charming and pleasant. He designed and lived in his own innovative floating home (houseboat) on Lake Union in Seattle. He was an avid and very competitive sailor who designed a state-of-the-art sailboat in which he raced worldwide in races such as the famous Sydney-Hobart race. Dick was also very active and competitive in water sports, particularly in rowing crew races. Dick will be sorely missed, not only by those of us in the tunneling industry but also by those in the many other fields of endeavor that he touched during his active life.”

Industry News, trenchless projects

Completion of Excavation a Landmark Event for High-Profile Wastewater Line

On May 23, 2019, a celebration was in order: The last of six 8.93 m (29.3 ft) diameter EPBs had completed excavation at Lot 4 of Mexico City’s Tύnel Emisor Oriente (TEO), a feat marking the completion of ten years and 62.1 km (38.6 mi) of tunneling. “We are proud of having successfully finished the excavation, despite all the adversities we faced, such as large inflows of water, hydraulic loads and constant changes in geology. We solved these by adapting the excavation mode according to each type of geology found,” said Hector Arturo Carrillo, Machinery Manager for Lot 4 contractor Carso Infraestructura y Construcción (CARSO).

On May 23, 2019, a celebration was in order: The last of six 8.93 m (29.3 ft) diameter EPBs had completed excavation at Lot 4 of Mexico City’s Tύnel Emisor Oriente (TEO), a feat marking the completion of ten years and 62.1 km (38.6 mi) of tunneling. “We are proud of having successfully finished the excavation, despite all the adversities we faced, such as large inflows of water, hydraulic loads and constant changes in geology. We solved these by adapting the excavation mode according to each type of geology found,” said Hector Arturo Carrillo, Machinery Manager for Lot 4 contractor Carso Infraestructura y Construcción (CARSO).

Despite multiple challenges, the operation achieved a project record of 30 m (98 ft) in one day, and a high of 528 m (1,732 ft) in one month. It’s a result that, Carillo says, has much to do with the continuous conveyor system being used for muck removal: “It should be noted that our advance rates were achieved thanks to the great Robbins conveyor design. The tunnel conveyor was composed with elements such as the booster, vertical belt, curve idlers, and advancing tail piece, as well as elements on the surface. Personally, I think it is a great, admirable system that has helped us achieve the TBM’s performance.”

The breakthrough was the latest and greatest milestone for an urgently needed wastewater project that spanned some of the most difficult geology ever encountered by EPBs. The 10.2 km (6.3 mi) long Lot 4, running from Shaft 17 to Shaft 13 at depths of up to 85 m (280 ft), included sections of basalt rock interspersed with permeable sands with high water pressure. “Our machines had to go through the worst geology, but they were designed for it,” said Roberto Gonzalez Ramirez, General Manager for Robbins Mexico, of the three Robbins EPBs and continuous conveyor systems used on Lots 3, 4, and 5 of the project.

The breakthrough was the latest and greatest milestone for an urgently needed wastewater project that spanned some of the most difficult geology ever encountered by EPBs. The 10.2 km (6.3 mi) long Lot 4, running from Shaft 17 to Shaft 13 at depths of up to 85 m (280 ft), included sections of basalt rock interspersed with permeable sands with high water pressure. “Our machines had to go through the worst geology, but they were designed for it,” said Roberto Gonzalez Ramirez, General Manager for Robbins Mexico, of the three Robbins EPBs and continuous conveyor systems used on Lots 3, 4, and 5 of the project.

All of the machines were designed for water pressures from 4 to 6 bars, with mixed ground, back-loading cutterheads to tackle variable ground conditions. High pressure, tungsten carbide knife bits could be interchanged with 17-inch diameter carbide disc cutters depending on the geology. Other features included man locks and material locks designed to withstand pressures up to 7 bar, a redesigned bulkhead, and Hardox plates to reinforce the screw conveyors as well as removable wear plates to further strengthen each screw conveyor flight. The rotary union joint was redesigned to improve cutter change times during cutterhead interventions, while a new scraper design offered more impact resistance in mixed ground conditions with rock.

The Lot 4 TBM was assembled in the launch shaft no. 17 and commissioned in August 2012, with the bridge and all the back-up gantries at the surface. Two months later in October 2012, after advancing 150 m (490 ft), the machine and its back-up were completely assembled in the tunnel. One month later, the continuous conveyor system was installed and running.

After 405 m (1,328 ft) of excavation, the presence of rocks, scrapers, parts of the mixing bars and other wear materials in the excavated muck prompted a cutterhead inspection. With high pressure up to 3.5 bars, it was determined that a hyperbaric intervention was necessary, and on June 2nd, 2013 the first hyperbaric intervention through an EPB in a tunnel was performed in Mexico. However, these interventions were done at great cost and proved to be time-consuming. After about 50 hyperbaric interventions the remainder of the project’s interventions were done in open air. “The interventions carried out in atmospheric mode were the biggest challenge. The great influx of water tested the limits, because we were excavating on a decline. In all of these interventions we had to implement a double pumping system, at both the TBM and the shaft,” said Carrillo. Despite the challenges of pumping water at volumes up to 180 l (48 gal) per second and cleaning fines from the tunnel each time the operation was performed, atmospheric interventions were still lower in cost and quicker than those done at hyperbaric pressure.

Even when conditions were tough, Carrillo felt his operation was well-supported by Robbins Field Service: “Robbins were always present giving ideas and contributing all their experience to solve the problems. One of the most recent examples, almost at the end of this project, was where the machine encountered a blockage to the shield and could not move forward. It became necessary to implement the exceptional pressure hydraulic system, reaching a pressure range of 596 bar on 28 thrust cylinders. Robbins personnel helped us during all that time and we were able to get through it.”

Image 1: On May 23, 2019, a Robbins 8.93 m (29.3 ft) diameter EPB completed the final lot of Mexico City’s Tύnel Emisor Oriente (TEO). Capping 62.1 km (38.6 mi) of tunneling.

Image 2: The Robbins crew celebrates the breakthrough of the Robbins EPB at Lot 4 of TEO, after boring 10.2 km in some of the most difficult geology in Mexico.

Visit the Robbins website for more information.

Industry News, trenchless people

THOMPSON, CONNECTICUT USA, May 1, 2019:

THOMPSON, CONNECTICUT USA, May 1, 2019:

Numa, the world’s leading drilling technology provider, has announced the appointment of Mark Stickney to the position of Chief Financial Officer. Mark will succeed Joe Tokarz, who served as CFO for over 30 years and retired in April 2019.

Mark is a finance leader with a proven track record of driving performance and process improvements in highly diversified manufacturing businesses. He brings over 25 years of top level financial experience and leadership to the organization. This is Mark’s second stint with Numa as he was previously a Senior Cost Accountant for the company in the late 1990’s.

“We are very pleased to welcome back Mark as our new CFO,” said Numa President, Ralph Leonard. “Mark’s past experience with Numa and his deep expertise in operational finance makes him uniquely qualified for this role. We look forward to him joining our leadership team and helping us execute on our growth plans while maximizing profitability.”

Prior to joining Numa, Mark served in various finance and accounting management roles for Saint-Gobain Ceramics & Plastics, Inc. (Euronext: ISIN FR0000125007), a multinational corporation that produces a variety of construction and high-performance materials. In his most recent role, he was Director of Finance Worldwide where he supported a multi-million dollar manufacturing division with multiple global locations. His responsibilities focused on business outcomes and efficient and effective business processes. He holds both a MBA and Bachelors of Science degree in Accounting from the Nichols College.

“I’m very excited to re-join Numa,” Mark stated. “Numa is well known for its industry-leading products and service, which make it possible for its customers to quickly solve complex drilling challenges. I look forward to applying my experience to help drive growth and profit for the business.”

ABOUT NUMA

Numa is the world’s leading drilling technology provider, dedicated to ongoing product innovation and results-oriented consistency. We’ve built a strong legacy of high quality, U.S. made hammers and bits for drilling holes 3½ – 50½ inches (89 -1283 mm) in diameter. With over 100 hammer and bit products serving 11 different industries, our products are capable of drilling vertical, horizontal, and reverse circulation holes in hard rock and unconsolidated formations.

Industry News, trenchless people

Jason Dewitt joins the Vermeer team with 12 years of experience of various equipment industry roles

Jason Dewitt joins the Vermeer team with 12 years of experience of various equipment industry roles

GREENVILLE, South Carolina, May 28, 2019 — Vermeer MV Solutions is building upon its already strong customer service in the drilling industry with the addition of Jason Dewitt as the new west coast regional sales manager based out of Exeter, California. In his new role, Dewitt will manage sales activities within his region and provide quality support to the dealers in those territories by determining dealer sales and marketing needs.

Over the years, Dewitt has held various equipment sales roles with increasing responsibilities — including previous positions with Vermeer Pacific and Vermeer Rocky Mountain. He has also served in the United States Air Force and as a police officer in Billings, Montana, and Visalia, California.

“Jason’s previous roles in equipment sales and his career as a police officer have molded him into an efficient leader with a team-oriented mindset,” said Vermeer MV Solutions director of sales Brian Showley. “We have no doubt that he will be able to hit the ground running with his passions for building strong relationships and providing quality customer service.”

Learn more about Vermeer MV Solutions by visiting Vermeer.com.

Industry News, trenchless people, trenchless projects

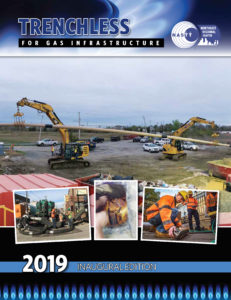

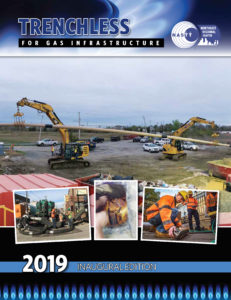

The Northeast Chapter of NASTT has launched a magazine that will be beneficial to the gas industry across the United States.

The Northeast Chapter of NASTT has launched a magazine that will be beneficial to the gas industry across the United States.

The inaugural issue of Trenchless for Gas Infrastructure magazine is now available as a complementary download. Trenchless for Gas Infrastructure magazine provides understanding, knowledge and technical innovations regarding the specific application of trenchless technology methods for gas distribution and transmission networks.

Trenchless for Gas Infrastructure is focused on the utility and application of trenchless methods in gas distribution pipeline repair and new construction programs. Content includes articles and case studies demonstrating the benefits of using trenchless technology to repair replace and upgrade gas distribution networks.

The magazine is distributed to senior gas operations and construction executives, engineers and consultants, reaching gas utility LDCs across the US. It is also available as a free download on the NASTT website.

Industry News, trenchless products

KOBUS SERVICES are delighted to announce that the business has won the Abbott Award for Innovative Products & Services for their KPP400 series Pipe Puller at the recent NASTT No-Dig Show in Chicago.

KOBUS SERVICES are delighted to announce that the business has won the Abbott Award for Innovative Products & Services for their KPP400 series Pipe Puller at the recent NASTT No-Dig Show in Chicago.

The award, bestowed by a specially selected judging panel, was given during the show in appreciation of the truly ground-breaking and innovative nature of the product.

The Kobus Pipe Puller KPP400 series has been recognized as the next generation in efficient and effective trenchless rehabilitation pipe repair and replacement technology.

The award recognizes the effort and investment that has been placed into the development of a system designed to help significantly impact the global problem of old service pipes falling into disrepair, leaking, reaching end of life or creating water quality issues.

Kobus Pipe Puller enables the trenchless replacement of gas and water service pipes connecting mains to properties the world over. Now in use in UK, North America, and Australasia, the benefits of the system include less disruption before, during and after works, lower reinstatement costs, higher productivity and overall reduced cost.

Kobus Pipe Puller enables the trenchless replacement of gas and water service pipes connecting mains to properties the world over. Now in use in UK, North America, and Australasia, the benefits of the system include less disruption before, during and after works, lower reinstatement costs, higher productivity and overall reduced cost.

There are also compelling ecological and environmental benefits in completely removing the old pipes from the ground, something other techniques cannot guarantee, eliminating the potential environmental damage leaving it in situ may cause.

Tom Atienza and Simon Drain gratefully received the Award during the show and were mentioned during a presentation at the Gala Dinner.

“The Award was a big surprise as this was our first time visiting and exhibiting at the No Dig Show. NASTT have been enthusiastic supporters of Kobus Pipe Puller and we’ve been working hard to build a North America customer base, which obviously has huge potential and has been very welcoming” said Tom Atienza, operations director.

“We’re grateful to NASTT, sponsors and Benjamin Media for a well-organized No-Dig Show, and congratulations to the other entrants in the Innovative Products Award category”.

Visit kobuspipepuller.com to learn more how Kobus Pipe Puller 300 series (free standing) and 400 series (excavator mounted) can significantly enhance your pipe removal operation.

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

Salt Lake City Public Utilities is increasing capacity and upgrading a portion of their sanitary sewer collection system from 1500 S – 2700 W to Redwood Road. The project bid in January 2019 and Whitaker Construction was selected as the low bidder. BTrenchless Inc. was awarded the grade-critical tunneled crossing of I-215, a major interstate in Salt Lake City. The tunnel was designed as a 466LF long, 48″ diameter steel casing with a future 30″ HOBAS carrier pipe skid in it afterwards. BTrenchless decided to upsize the casing to 51″ diameter to match the dimensions of their Akkerman SL51 Microtunnel Boring Machine (MTBM). The center of the tunnel was about 7FT below the water table with extremely soft soil consisting of lean clay, fat clay, and silty sand. This type of ground water and soil condition suits itself well for a MTBM installation method.

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the

PELLA, Iowa, – With 24 locations throughout Michigan and Indiana, MacAllister Rentals, the region’s authorized CAT Rental Store, rents, sells, and services a wide range of high-quality equipment from Caterpillar and over 50 other manufacturers. As a part of the Indiana-based and family-owned MacAllister Machinery, MacAllister Rentals has an impeccable reputation for supplying contractors with first class service, in-depth technical knowledge, and top-notch equipment including the  June, 2019 (Pella, IA)

June, 2019 (Pella, IA)  It is with deep sadness that

It is with deep sadness that  On May 23, 2019, a celebration was in order: The last of six 8.93 m (29.3 ft) diameter EPBs had completed excavation at Lot 4 of Mexico City’s Tύnel Emisor Oriente (TEO), a feat marking the completion of ten years and 62.1 km (38.6 mi) of tunneling. “We are proud of having successfully finished the excavation, despite all the adversities we faced, such as large inflows of water, hydraulic loads and constant changes in geology. We solved these by adapting the excavation mode according to each type of geology found,” said Hector Arturo Carrillo, Machinery Manager for Lot 4 contractor Carso Infraestructura y Construcción (CARSO).

On May 23, 2019, a celebration was in order: The last of six 8.93 m (29.3 ft) diameter EPBs had completed excavation at Lot 4 of Mexico City’s Tύnel Emisor Oriente (TEO), a feat marking the completion of ten years and 62.1 km (38.6 mi) of tunneling. “We are proud of having successfully finished the excavation, despite all the adversities we faced, such as large inflows of water, hydraulic loads and constant changes in geology. We solved these by adapting the excavation mode according to each type of geology found,” said Hector Arturo Carrillo, Machinery Manager for Lot 4 contractor Carso Infraestructura y Construcción (CARSO). The breakthrough was the latest and greatest milestone for an urgently needed wastewater project that spanned some of the most difficult geology ever encountered by EPBs. The 10.2 km (6.3 mi) long Lot 4, running from Shaft 17 to Shaft 13 at depths of up to 85 m (280 ft), included sections of basalt rock interspersed with permeable sands with high water pressure. “Our machines had to go through the worst geology, but they were designed for it,” said Roberto Gonzalez Ramirez, General Manager for Robbins Mexico, of the three Robbins EPBs and continuous conveyor systems used on Lots 3, 4, and 5 of the project.

The breakthrough was the latest and greatest milestone for an urgently needed wastewater project that spanned some of the most difficult geology ever encountered by EPBs. The 10.2 km (6.3 mi) long Lot 4, running from Shaft 17 to Shaft 13 at depths of up to 85 m (280 ft), included sections of basalt rock interspersed with permeable sands with high water pressure. “Our machines had to go through the worst geology, but they were designed for it,” said Roberto Gonzalez Ramirez, General Manager for Robbins Mexico, of the three Robbins EPBs and continuous conveyor systems used on Lots 3, 4, and 5 of the project. THOMPSON, CONNECTICUT USA, May 1, 2019:

THOMPSON, CONNECTICUT USA, May 1, 2019: Jason Dewitt joins the Vermeer team with 12 years of experience of various equipment industry roles

Jason Dewitt joins the Vermeer team with 12 years of experience of various equipment industry roles The Northeast Chapter of NASTT has launched a magazine that will be beneficial to the gas industry across the United States.

The Northeast Chapter of NASTT has launched a magazine that will be beneficial to the gas industry across the United States.