Blog, Industry News, trenchless people

Cleveland, Ohio – The North American Society for Trenchless Technology (NASTT) celebrates 30 years of industry advocacy and education in 2020. NASTT is an engineering society of individuals, public organizations and private companies with strong beliefs in the practical, social and environmental benefits of trenchless technology.

Cleveland, Ohio – The North American Society for Trenchless Technology (NASTT) celebrates 30 years of industry advocacy and education in 2020. NASTT is an engineering society of individuals, public organizations and private companies with strong beliefs in the practical, social and environmental benefits of trenchless technology.

Founded in 1990, NASTT represents nearly 2,400 members throughout the United States, Canada and Mexico who all promote better and more responsible ways to manage underground infrastructure. NASTT’s mission is to advance trenchless technology and to promote its benefits for the public and the natural environment by increasing awareness and knowledge through technical information dissemination, research and development, education and training.

As NASTT continues to grow and take on new challenges, it is important for the not-for-profit Society to serve and support their diverse industry partners. NASTT proudly represents municipalities and public utilities, consultants and engineers, manufacturers and suppliers, trenchless contractors and academia. NASTT reaches out to all these groups and shares with the community the latest industry trenchless advancements and their continuing education opportunities. For 30 years, the all-volunteer members of NASTT have presented non-commercial information seminars and training about these “green alternative” engineering methods to North American communities.

The annual NASTT No-Dig Show is the Society’s flagship educational and networking event. This conference and trade show offers 160 quality, non-commercial technical papers; an exhibition hall with more than 200 trenchless companies displaying their products and services; a series of specialized trenchless training courses, plus many entertaining networking events and special industry related awards. The NASTT No-Dig Show is the largest trenchless technology conference in the world averaging over 2,000 industry professionals.

In 2019 the Canadian Regional Chapters of NASTT hosted the inaugural No-Dig North conference. Nearly 600 attendees from across Canada met in Calgary, AB to learn from each other, network and discuss all things trenchless. This show will be an annual event with the 2020 No-Dig North being held October 19-21 in Vancouver, BC.

In celebration of its 30th Anniversary, NASTT will look back at the history of the Society with a series of Flashback Friday (#fbf) social media posts along with various activities throughout 2020. You are invited to join in a celebratory toast during the NASTT 2020 No-Dig Show Opening Ceremony Ribbon Cutting in Denver, Colorado on Monday, April 6 at the Colorado Convention Center.

Blog, Industry News, trenchless people

Tri-State Utilities enters their 30th year of operation in 2020. As they look forward to new leadership and direction, they are excited to announce the following promotions and present their management staff.

Tri-State Utilities enters their 30th year of operation in 2020. As they look forward to new leadership and direction, they are excited to announce the following promotions and present their management staff.

Tri-State Utilities is pleased to announce that Jonathan Thomas, PE has been promoted to Vice-President / General Manager and will lead them into the new decade. With 10 years of project management experience at Tri-State Utilities, Jonathan will be overseeing the Chesapeake, Virginia and the Winston-Salem, NC offices. The addition of Jonathan to the Senior Management team will position the company for continued growth in Virginia, North Carolina, and South Carolina.

Tri-State Utilities is pleased to announce that Jonathan Thomas, PE has been promoted to Vice-President / General Manager and will lead them into the new decade. With 10 years of project management experience at Tri-State Utilities, Jonathan will be overseeing the Chesapeake, Virginia and the Winston-Salem, NC offices. The addition of Jonathan to the Senior Management team will position the company for continued growth in Virginia, North Carolina, and South Carolina.

Ron Parsons has been promoted to Vice-President of Operations. With 15 years of experience at Tri-State Utilities, Ron will now lead field operations to bring a continued expertise in Cleaning & CCTV services and CIPP (Cured-In-Place Pipe) Lining. Ron started his career as a Vactor operator and has held positions as a CIPP cutter operator, CIPP Foreman and Superintendent. Ron has invaluable experience cleaning and lining pipe of all sizes and possesses great personnel management skills.

Ron Parsons has been promoted to Vice-President of Operations. With 15 years of experience at Tri-State Utilities, Ron will now lead field operations to bring a continued expertise in Cleaning & CCTV services and CIPP (Cured-In-Place Pipe) Lining. Ron started his career as a Vactor operator and has held positions as a CIPP cutter operator, CIPP Foreman and Superintendent. Ron has invaluable experience cleaning and lining pipe of all sizes and possesses great personnel management skills.

Craig Welsh will now lead the Estimating Department in addition to his role as a Project Manager. With 16 years of experience at Tri-State Utilities, Craig will oversee an estimating department that will focus on Cleaning & CCTV services, CIPP (Cured-In-Place Pipe) Lining, and traditional open-cut storm, sewer, and water line services. Craig’s experience with site work as well as rehabilitation methods provides him with a unique skill set for providing accurate estimates for Tri-State to build.

Craig Welsh will now lead the Estimating Department in addition to his role as a Project Manager. With 16 years of experience at Tri-State Utilities, Craig will oversee an estimating department that will focus on Cleaning & CCTV services, CIPP (Cured-In-Place Pipe) Lining, and traditional open-cut storm, sewer, and water line services. Craig’s experience with site work as well as rehabilitation methods provides him with a unique skill set for providing accurate estimates for Tri-State to build.

John Saintsing is the Business Development Manager for Virginia, North Carolina, and South Carolina. With seven years of experience at Tri-State Utilities, John will continue to explore new, better and innovative methods for CCTV services and CIPP (Cured-In-Place Pipe) technologies. John’s responsibilities will include attendance to industry conferences, building key customer relationships, and developing new services and products in Infrastructure Rehabilitation.

John Saintsing is the Business Development Manager for Virginia, North Carolina, and South Carolina. With seven years of experience at Tri-State Utilities, John will continue to explore new, better and innovative methods for CCTV services and CIPP (Cured-In-Place Pipe) technologies. John’s responsibilities will include attendance to industry conferences, building key customer relationships, and developing new services and products in Infrastructure Rehabilitation.

Sean Merryman was hired last year as the Business Development and Project Manager for the southwest North Carolina region and South Carolina. Sean will maintain a heavy presence in the area while establishing a new lining crew and Clean & TV crew to service this growing region. Tri-State Utilities is very excited about the experience Sean brings with him from his previous employer and the opportunity to service municipalities and engineers who have historically been outside of our footprint.

Sean Merryman was hired last year as the Business Development and Project Manager for the southwest North Carolina region and South Carolina. Sean will maintain a heavy presence in the area while establishing a new lining crew and Clean & TV crew to service this growing region. Tri-State Utilities is very excited about the experience Sean brings with him from his previous employer and the opportunity to service municipalities and engineers who have historically been outside of our footprint.

Connor Mathis is a Project Manager with eight years of experience at Tri-State Utilities. Connor will manage projects throughout Virginia, North Carolina, and South Carolina while focusing most of his time on the Construction Services contracts for the Cities of Norfolk and Virginia Beach. These services include: Cleaning and CCTV, CIPP Sectional Liners, Rausch Repair Sleeves, and CIPP (Cured-In-Place Pipe) for Storm and Sanitary Pipe Rehabilitation. Connor is also certified in land disturbance and manages all heavy excavation work, road repairs and off-road ditch maintenance.

Connor Mathis is a Project Manager with eight years of experience at Tri-State Utilities. Connor will manage projects throughout Virginia, North Carolina, and South Carolina while focusing most of his time on the Construction Services contracts for the Cities of Norfolk and Virginia Beach. These services include: Cleaning and CCTV, CIPP Sectional Liners, Rausch Repair Sleeves, and CIPP (Cured-In-Place Pipe) for Storm and Sanitary Pipe Rehabilitation. Connor is also certified in land disturbance and manages all heavy excavation work, road repairs and off-road ditch maintenance.

James Farris is a Project Manager with a total of six years of experience in utility construction and the last four years with Tri-State Utilities. He has gained valuable experience on Consent Order driven inspection and rehabilitation of storm and sanitary sewer systems. Before coming to work at Tri-State Utilities, James spent four years with Real Estate Improvement, a Virginia Beach based Class A construction company. Prior to that, James was with Norfolk Southern Railway for eight years focusing his efforts primarily on customer service, purchasing, and sales.

James Farris is a Project Manager with a total of six years of experience in utility construction and the last four years with Tri-State Utilities. He has gained valuable experience on Consent Order driven inspection and rehabilitation of storm and sanitary sewer systems. Before coming to work at Tri-State Utilities, James spent four years with Real Estate Improvement, a Virginia Beach based Class A construction company. Prior to that, James was with Norfolk Southern Railway for eight years focusing his efforts primarily on customer service, purchasing, and sales.

Rick Sharp is the newest member and Project Manager of the Tri-State Utilities’ team. Rick brings with him over 15 years of project management experience from residential and commercial construction as well as land development. Rick will be managing projects throughout Virginia, North Carolina, and South Carolina.

Rick Sharp is the newest member and Project Manager of the Tri-State Utilities’ team. Rick brings with him over 15 years of project management experience from residential and commercial construction as well as land development. Rick will be managing projects throughout Virginia, North Carolina, and South Carolina.

Andy McSweeney will continue to lead Tri-State Utilities as Vice-President of Project Management with a focus on Estimating and Business Development as they grow their footprint deeper into North and South Carolina.

Andy McSweeney will continue to lead Tri-State Utilities as Vice-President of Project Management with a focus on Estimating and Business Development as they grow their footprint deeper into North and South Carolina.

Joe McSweeney, after 27 years of service with Tri-State Utilities, has decided to retire. A career that included responsibilities of a CCTV Operator, CIPP Foreman and Superintendent, and Vice-President of Operations. A career full of accomplishments and a future full of possibilities. Tri-State Utilities wishes Joe much more success in his future endeavors.

Joe McSweeney, after 27 years of service with Tri-State Utilities, has decided to retire. A career that included responsibilities of a CCTV Operator, CIPP Foreman and Superintendent, and Vice-President of Operations. A career full of accomplishments and a future full of possibilities. Tri-State Utilities wishes Joe much more success in his future endeavors.

The management team of Tri-State Utilities is can all be reached at (757) 366-9505. Visit their website for more information on the company.

Blog, Industry News, trenchless projects

Compact TBM bores longest Rock Tunnel at 2.46 m Diameter

In August 2019, a small diameter Double Shield TBM made a big impact. The 2.46 m (8.07 ft) diameter Robbins machine completed 3,475 m (11,400 ft) of boring with no intermediate access, making it the longest rock tunnel ever bored by a Double Shield TBM under 2.5 m (8.2 ft) in diameter.

In August 2019, a small diameter Double Shield TBM made a big impact. The 2.46 m (8.07 ft) diameter Robbins machine completed 3,475 m (11,400 ft) of boring with no intermediate access, making it the longest rock tunnel ever bored by a Double Shield TBM under 2.5 m (8.2 ft) in diameter.

The machine completed the Parmer Lane Wastewater Interceptor in Austin, Texas, USA for contractor S.J. Louis Construction. Despite obstacles including two tight curves of 150 m (500 ft) radius and unexpected ground conditions that required modification of the cutterhead in the tunnel, advance rates were good. The machine reached up to 380 m (1,250 ft) per month while mining in single 12-hour shifts per day. “It was a hard rock TBM, and it performed better than expected through hard rock,” said Zach West, Project Manager for S.J. Louis.

The challenges for the TBM and its crew were varied, explained West. “The pairing of this tunnel length, which is on the longer side, and the diameter, which is on the smaller side, is challenging. The survey in a small tunnel with tight radius curves and limited surface access for over two miles is very difficult.” He added that the shallow tunnel depth, and the alignment to within a few feet of sanitary lines, high-pressure gas mains, and fuel tanks for gas stations, made TBM guidance critical. “I would say that I am most proud of our ability to guide the machine successfully through these obstacles and into our retrieval shaft within our expected tolerances.”

Through one stretch, the tunnel advanced directly between a 30 cm (12 in) diameter, high-pressure gas main and fuel tanks for a gas station with limited as-built information. “Navigating this section took a great deal of coordination with the local utility companies. Because the tunnel diameter was too small for an automated guidance system, we manually surveyed the front of the machine at every push to ensure the machine was on track,” said West.

Through one stretch, the tunnel advanced directly between a 30 cm (12 in) diameter, high-pressure gas main and fuel tanks for a gas station with limited as-built information. “Navigating this section took a great deal of coordination with the local utility companies. Because the tunnel diameter was too small for an automated guidance system, we manually surveyed the front of the machine at every push to ensure the machine was on track,” said West.

“I’m proud that they mined the longest tunnel to date for a small shielded gripper machine of this size without any safety issues. Kudos to their management philosophy and jobsite team,” said Tom Fuerst, Robbins Utility Tunneling Sales Manager. Robbins assisted the crew while in the tight 150 m (500 ft) curves and helped with modifications required to the cutterhead and disc cutter arrangement.

The tunnel is located in an environmentally sensitive aquifer, with ground conditions ranging from soft dolomite with clay to limestone from 13 to 68 MPa (2,000 to 10,000 psi) UCS. “While we tunneled through the softer material, our best advance rate was close to 0.9 m (3 ft) per hour. When we tunneled through the expected limestone, advance rates were over 5.2 m (17 ft) per hour. Our best day was 25 m (81 ft) in a single shift,” said West.

The tunnel is located in an environmentally sensitive aquifer, with ground conditions ranging from soft dolomite with clay to limestone from 13 to 68 MPa (2,000 to 10,000 psi) UCS. “While we tunneled through the softer material, our best advance rate was close to 0.9 m (3 ft) per hour. When we tunneled through the expected limestone, advance rates were over 5.2 m (17 ft) per hour. Our best day was 25 m (81 ft) in a single shift,” said West.

The majority of the tunnel used a simple two-rock-bolt pattern for support. In the last 10% of the tunnel, ribs and lagging were used as support. Final carrier pipe, which is now being installed, consists of 110 cm (42 in) diameter fiberglass pipe.

The successful project is part of a larger trend towards small diameter, TBM-driven rock tunnels in the United States, says Fuerst. “It is primarily due to demographics and business growth. The parts of the USA that are growing need to build out their sewer and water infrastructure. TBMs can mine long distances with tight curves. They can reduce the need for multiple shafts, which lowers the overall project cost. And, given that most small diameter pipelines follow a road or municipal right-of-way, traffic problems are reduced significantly compared with open cut operations.”

The Parmer Lane Wastewater Interceptor connects to two existing lift stations at Lake Creek and Rattan Creek. The tunnel allows for these lift stations to be decommissioned, and will provide additional flow capacity by gravity, reducing operating costs for the City of Austin.

The Parmer Lane Wastewater Interceptor connects to two existing lift stations at Lake Creek and Rattan Creek. The tunnel allows for these lift stations to be decommissioned, and will provide additional flow capacity by gravity, reducing operating costs for the City of Austin.

Image 1: Completed in August 2019 with a Robbins Double Shield TBM, the Parmer Lane Wastewater Interceptor will provide additional flow capacity via gravity in Austin, Texas, USA.

Image 2: The 3,475 m (11,400 ft) tunnel bored by a Robbins TBM is the longest ever bored by a Double Shield machine under 2.5 m (8.2 ft) in diameter.

Image 3: The S.J. Louis Construction crew celebrate the successful and safe completion of the Parmer Lane Wastewater Interceptor with a Robbins TBM.

Image 4: Tom Fuerst, Robbins Utility Tunneling Sales Manager, celebrates as he exits the TBM during its August 2019 breakthrough in Austin, Texas, USA.

Image 5: The Robbins TBM bored through dolomite with clay and limestone at rates of up to 380 m (1,250 ft) in one month while mining in single 12-hour shifts per day.

Blog, Industry News, trenchless people, trenchless projects

Today’s blog post is a guest post from Ted Roberts. Ted is a Minnesota-based attorney and NASTT member focused on helping contractors steer through project disputes and other legal obstacles. He welcomes feedback about this article and may be reached at ted@tedrobertslaw.com or on LinkedIn at linkedin.com/in/hddlawyer. His website—www.directionaldrillinglaw.com—is currently under construction.

Today’s blog post is a guest post from Ted Roberts. Ted is a Minnesota-based attorney and NASTT member focused on helping contractors steer through project disputes and other legal obstacles. He welcomes feedback about this article and may be reached at ted@tedrobertslaw.com or on LinkedIn at linkedin.com/in/hddlawyer. His website—www.directionaldrillinglaw.com—is currently under construction.

In this article I share five rules for getting paid faster with fewer objections. The five rules are distilled from my experience litigating lawsuits stemming from horizontal directional drilling projects. Reflecting on what the parties were fighting about in those cases, I tried to come up with a set of “best practices” that, had they been followed in the cases I handled, might have prevented a lawsuit in the first place or at least reduced the time and expense needed to resolve it.

Any contractor who implements these practices will see three benefits. First, the contractor will encounter fewer objections to payment. Second, any objections will be resolved sooner without the need to resort to a lawsuit. Finally, any payment disputes will be resolved on better terms—that is, the contractor will see more money sooner. While there exist additional ways to avoid claims on a project, I have focused on actions contractors can take without much trouble or expense.

As detailed below, the five rules are:

- Write down the important stuff.

- Treat your contract as a rulebook, not something to be signed and filed away.

- Thoroughly document any extras now, not later.

- Preserve your lien and bond rights.

- Make sure the contract you want is the contract you get.

Write down the important stuff.

Easy to remember and easy to do: document important communications and events in writing, when they happen. I do not think I exaggerate when I say that many lawyers would be out of a job if more contractors lived by this principle: “If it’s not in writing, it never happened.”

While most of us know that contracts should be in writing, many contractors still find themselves fighting over incidental agreements and commitments made during the project’s performance. Because these are often the result of a conversation or meeting, no one bothers to make a record. While I am not suggesting that someone transcribe everything said on the job site, my own experience suggests that many disputes could be avoided had the parties documented their agreement in writing.

Here are some examples of the types of discussions and agreements that should be documented:

- Agreements about the cause or mitigation of any defective work or property damage.

- Commitments to pay for extra work or changes in the work.

- Agreements to accept non-conforming work or a substitute performance.

- Agreements to modify the original contract, including agreements to ignore (that is, “waive”) any contract requirements.

- Agreements to modify the schedule or project deadlines.

Unless the contract requires something different, written documentation need not be lengthy or formal: a quick email can be enough, or a hand-written note signed by both sides.

Treat your contract as a rulebook, not something to be signed and filed away.

Good construction contracts anticipate and address the issues most likely to cause problems on an HDD project. These include what are commonly known as “project risks” or “construction risks”: delays, frac-outs, and unexpected subsurface conditions, for example.

All of these risks can negatively impact the project by either increasing either the time or costs required to complete the work. The occurrence of any of these events should trigger an immediate review of the contract. Chances are, the contract will provide specific instructions on how the contractor should respond, especially if the contractor intends to ask for additional time or money as a result. More often than not, the contract will require written notice and other documentation within a short period of time. A contractor who ignores these requirements is at risk of losing any rights to additional time or money.

Events that impact a project’s schedule and cost are not the only reason to take a second look at your contract. Refer to your contract whenever:

- The parties want to modify the contract’s terms or the scope of work.

- One of the parties has defaulted—that is, failed to perform—on one of its obligations.

- One of the parties wants to terminate or abandon the contract before completion.

All of the above assumes that your contract actually has something to say about these issues. Good construction contracts will address these issues and most do.

Some contracts, especially lower-tier subcontracts, do not. I have encountered more than one subcontract limited to a one-page proposal, without much else. If you are dealing with such a contract, then proceed with caution and consult a lawyer.

Thoroughly document any extras now, not later.

It is not uncommon for a contractor to incur additional, unexpected costs on a project through no fault of its own. Delays, contract changes and extras, and differing site conditions may all negatively impact the bottom line. And a contractor may have the right to be reimbursed for these costs. But a right to payment is only half the battle. The legal right to be paid means nothing if the contractor is unable to show what its actual costs were.

You may have heard this in math class: “Show your work.” This is also a good rule to follow when documenting any extras on a job. A contractor who is incurring extra costs should keep two goals in mind. The first goal is to segregate the extra costs so they can be easily distinguished from costs related to the work under the contract. The second is to show that the extra costs were the result of a specific cause; for example, extra costs attributable to delayed site access.

Detailed contemporaneous documentation can only help your cause. Paper the file. Was your work or equipment damaged? Assign a separate job-cost accounting code and document the damage and repairs with photographs and daily work records. Did you attempt to limit or contain your costs? Document that. If your schedule was impacted, make any necessary changes to your schedule. Was the matter discussed? Any discussions, agreements, and resolutions should be noted in writing when they happen.

Here’s what NOT to do. Do not wait until the end of the project and attempt to “guesstimate” your extra costs. Back-of-the-envelope cost calculations are rarely acceptable, either to those paying the bill or to a judge and jury sitting in a courtroom.

Preserve your lien and bond rights.

Mechanic’s liens and payment bonds are among the most valuable tools available to an unpaid contractor. This is so for two primary reasons. First, lien and bond claims allow a contractor to recover its attorneys fees in most cases. Second, both offer another source of payment—a second set of pockets—to pursue when your customer is either unwilling or unable to pay. And if your customer is insolvent, or declares bankruptcy, a lien or bond may be your only way to get paid.

Liens and payment bonds are often not treated with the respect they deserve. The leverage and power of a lien or bond claim should not be underestimated. A contractor with a valid lien or bond claim is a lot harder to ignore and a lot more expensive to fight. The threat of attorney’s fees, or the pressure exerted by the owner of property that has been liened, may be enough to motivate the other side to drop its objections and resolve a payment claim sooner.

Here’s a rough guide for contractors wanting to keep these two weapons in their arsenal. Before starting work on a project, a contractor should, either by itself or with the help of a lawyer, answer these three questions:

- Do I have the right to file a lien or a payment bond claim if I am not paid?

- If so, are there any notice or filing requirements I must satisfy before starting the work?

- If I am not paid, what are the notice and claim requirements I must follow after completing the work?

Of these three, the third is the one most often bungled. Know this: many lien and bond laws impose strict deadlines upon a contractor wanting to assert a claim. Many contractors allow these remedies to lapse as they continue to negotiate with their customer. For this reason, I suggest that contractors know what they need to do before starting the work and, as they close out their project, calendar any deadlines for filing a lien or taking action against a payment bond.

Make sure the contract you want is the contract you get.

Expensive claims and lawsuits do not happen simply because something goes wrong on a project. Even if a project’s costs suddenly increase because of the unexpected—bad geotechnical conditions, for example—an expensive lawsuit is unlikely if the issue has been addressed by the parties’ contract.

The seeds of a lawsuit are often planted before the work is even started, when the contract is formed. This can happen when both sides believe they have entered into a contract but harbor different understandings about their rights and obligations. Unfortunately, many contractors do not fully appreciate the risks posed by the contract formation process until it is too late.

In my experience, this problem—both sides having conflicting ideas about the nature of their agreement—is present in a lot of disputes that end up in litigation. Common scenarios include Here are three ways I’ve seen this happen on HDD projects:

- In the middle of a project, Contractor A subcontracts with Contractor B to complete some HDD crossings. Contractor A’s contract with the project’s general contractor incorporates the project’s specifications. Contractor A’s subcontract with Contractor B is silent on this issue. After things go wrong, the two contractors litigate the question of whether Contractor B and its work is, like Contractor A, bound by the project specifications.

- In the middle of a project, Contractor A hires Contractor B to complete some HDD crossings. After a telephone conversation about the conditions that Contractor A has encountered so far, the parties sign a contract consisting of little more than a description of the work and price. After mobilizing to the project, Contractor B discovers that neither water nor lodging is available within 60 miles. To make matters worse, Contractor B encounters geotechnical conditions inconsistent with what Contractor A had described. After things go south, the parties litigate the issue of whether Contractor A had misrepresented the project’s subsurface conditions and whether Contractor B had a right to assume that water and lodging would be nearby.

- Contractor provides Owner with a price proposal for HDD work. The proposal includes a term sheet that includes provisions that entitle Contractor A to be paid for stand-by time and to adjust its price upwards if the geotechnical conditions are different than those indicated. Owner asks Contractor to sign a contract that reflects Contractor’s price but does not include the contractor’s term sheet. If Contractor signs the contract, there is a substantial risk that its term sheet has been nullified. As a result, the Contractor has effectively agreed to take on greater risk during the project, without an increase in its price.

Here’s the point: a contractor’s mishandling or misunderstanding of the contract formation process can be financially disastrous if things go wrong. Contractors can manage risks they know about and price their work accordingly. But unknown risks are more difficult manage effectively and as a result more costly if they occur.

Here are five ways to make sure the contract you want is the contract you get:

- Anything important to you or your price should be in writing, in your contract. “In your contract,” means the written documents that both sides have agreed to. It does not mean your bid or proposal, unless the contract expressly says it does.

- Do not rely or depend upon agreements and statements that precede your contract, unless they also find their way into the written contract.

- Do not rely on industry “customs” and “practices” to get what you want. A judge or jury will not care if it’s customary to pay stand-by time, or that no money is paid for an incomplete crossing, if neither issue is addressed in the contract.

- Make sure your set of contract documents is complete. This is a bigger problem than many contractors realize. Most subcontracts contain “flow down” clauses, provisions that incorporate the terms in an upstream contract; for example, the agreement between the general contractor and the project’s owner. The two contracts are not always consistent and, in some cases, the terms in the upstream contract may override or nullify the terms in the subcontract. If your contract incorporates other agreements or documents, it is important that you obtain and review these documents before signing the contract.

- Increase your contract literacy. Given that most contracts are signed without the involvement of a lawyer, most contractors would benefit from a better understanding of how contracts work and, especially, how to spot and understand terms most likely to cause trouble. Such terms include those that limit a contractor’s right to recover losses caused by the other side, indemnity clauses, warranty provisions, and disclaimers. To be honest, I have no idea how contractors wade through the legal mumbo-jumbo that passes for contract drafting these days, other than to learn from trial and error. However they do it, contractors should empower themselves to understand the terms commonly included in construction contracts and the business purposes they are meant to serve.

Closing Thoughts

Nobody wants to fight over a claim for extra money or time. Lawsuits are expensive not only in terms of fees paid to lawyers and experts, but also expensive in the time and resources that required to deal with them. The occurrence of a project risk alone lead does not usually lead to an expensive legal fight, though some type of significant cost-impact like a delay or differing site condition is a necessary ingredient. The expensive disputes that end up in court usually also entail some type of misunderstanding or mismanagement of the contracting process. The five rules discussed above, if successfully implemented, should go far in avoiding such missteps.

Blog, Industry News, trenchless people, trenchless products, trenchless projects

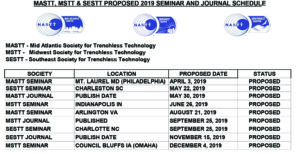

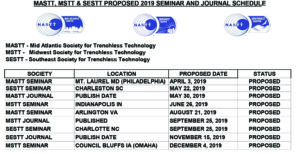

Please contact Leonard Ingram, PWAM, Executive Director, at leonard@engconco.com or call (888) 817-3788 to present, exhibit and/or sponsor food at these seminars.

Please contact Andrew Pattison, A to B Publishing, Inc. at marcomap@shaw.ca or call (204) 275-6946 to advertise in the journal or to discuss an article for the journal.

Blog, Industry News, trenchless products

January 1, 2019 ‐ Pipe Lining Supply has improved the Quik‐Shot™ lateral lining inversion unit. The unit now features a new improved nozzle design that allows the CIPP lateral lining material to flow through with ease, using the venturi process. The new design has improved the process so much we are offering a retrofit exchange program to rework any nozzles from existing customers. If you would like to participate in the exchange program, please contact us.

January 1, 2019 ‐ Pipe Lining Supply has improved the Quik‐Shot™ lateral lining inversion unit. The unit now features a new improved nozzle design that allows the CIPP lateral lining material to flow through with ease, using the venturi process. The new design has improved the process so much we are offering a retrofit exchange program to rework any nozzles from existing customers. If you would like to participate in the exchange program, please contact us.

Pipe Lining Supply is dedicated to research & development of all equipment and materials. This equipment improvement comes from many test trials and customer feedback. Being a leader in the industry is Pipe Lining Supply’s top priority.

About Pipe Lining Supply:

Pipe Lining Supply is a leader in the distribution of materials and equipment used in the lateral sewer lining and DWV rehabilitation businesses. The company was formed to support customers who need training and support as well as the equipment and materials to rehabilitate aging sewer laterals. Our goal is to serve the industry with a complete warehouse stocked with the best products at the lowest delivered cost on a timely basis. Our staff has many years of plumbing, excavating, pipe bursting, DWV coating and CIPP lining experience to share with its clients. In addition, we train and support installers throughout the USA to be the most knowledgeable and efficient in their goals.

For More Information:

Call: 888‐354‐6464

Visit: www.pipeliningsupply.com

Email: info@pipeliningsupply.com

Cleveland, Ohio – The North American Society for Trenchless Technology (NASTT) celebrates 30 years of industry advocacy and education in 2020. NASTT is an engineering society of individuals, public organizations and private companies with strong beliefs in the practical, social and environmental benefits of trenchless technology.

Cleveland, Ohio – The North American Society for Trenchless Technology (NASTT) celebrates 30 years of industry advocacy and education in 2020. NASTT is an engineering society of individuals, public organizations and private companies with strong beliefs in the practical, social and environmental benefits of trenchless technology.