Industry News, trenchless products

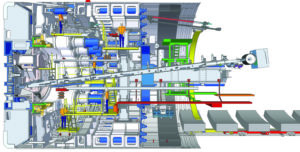

January 2020 – Pipe Lining Supply introduced its Quik‐Coating System in 2017. Today we are happy to announce the Quik‐Coating 2020 System. This system has the exact same core functionality as the initial model with a few exterior changes that have been requested from our customers. These items include a

January 2020 – Pipe Lining Supply introduced its Quik‐Coating System in 2017. Today we are happy to announce the Quik‐Coating 2020 System. This system has the exact same core functionality as the initial model with a few exterior changes that have been requested from our customers. These items include a

shorter unit (to fit in a standard cargo van), a stainless steel control plate, a scale shelf, a 4‐plug power strip, a powder‐coated (painted) frame and a tablet with important documentation pre‐loaded (no WiFi necessary).

Pipe Lining Supply is dedicated to research & development of all equipment and materials. This equipment improvement comes from many test trials and customer feedback. Being a leader in the industry is Pipe Lining Supply’s top priority.

About Pipe Lining Supply:

Pipe Lining Supply is a leader in the distribution of materials and equipment used in the lateral sewer lining and DWV rehabilitation businesses. The company was formed to support customers who need training and support as well as the equipment and materials to rehabilitate aging sewer laterals. Our

goal is to serve the industry with a complete warehouse stocked with the best products at the lowest delivered cost on a timely basis.

Our staff has many years of plumbing, excavating, pipe bursting, DWV coating, and, CIPP lining experience to share with its clients. Customer support is our #1 goal, we train and support installers throughout the USA to be the most knowledgeable and efficient in their goals.

For More Information:

Call: 888‐354‐6464

Visit: www.pipeliningsupply.com

Email: info@pipeliningsupply.com.

Quik‐Coating™ 2020 System shown with new improvements

Industry News, trenchless products, trenchless projects

40 Years after Original Tunnel, Robbins Returns to Russia

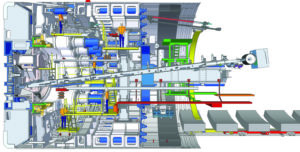

In 1979, a 4.56 m diameter Robbins Double Shield TBM was delivered to bore the Severomuysky Service Tunnel, a 15.3 km long railway through the remote mountains of Siberia. Now, 40 years after the original machine was delivered, Robbins is returning to the role. Two 10.37 m diameter Crossover (XRE) TBMs will bore the second Severomuysky Tunnel, clocking in at 15.5 km long and running through mixed ground and fault zones. The new rail line is needed due to limitations on carrying capacity on the current Baikal-Amur Mainline (BAM) railway through the area. Currently 16 million tonnes of cargo are carried through the existing Severomuysky tunnel but the Russian Government wants to increase cargo carrying capacity by more than six times in the region.

In 1979, a 4.56 m diameter Robbins Double Shield TBM was delivered to bore the Severomuysky Service Tunnel, a 15.3 km long railway through the remote mountains of Siberia. Now, 40 years after the original machine was delivered, Robbins is returning to the role. Two 10.37 m diameter Crossover (XRE) TBMs will bore the second Severomuysky Tunnel, clocking in at 15.5 km long and running through mixed ground and fault zones. The new rail line is needed due to limitations on carrying capacity on the current Baikal-Amur Mainline (BAM) railway through the area. Currently 16 million tonnes of cargo are carried through the existing Severomuysky tunnel but the Russian Government wants to increase cargo carrying capacity by more than six times in the region.

The largest global anthracite producer, Sibanthracite Group, is taking on the tunnel construction with management by VostokCoal Management Company. The companies, owned by Dmitry Bosov, aim to increase coal transport by up to 100 million tonnes per year through the addition of the second tunnel. “Robbins has established itself on the market as the best manufacturer of hard rock machines, which are able to provide the maximum penetration rate in hard rock. This is one of the determining factors in connection with the tight deadlines for the implementation of our project. Also, Robbins is the only manufacturer to build the Crossover TBM,” said a representative of Sibanthracite Group. Other aspects of the supply include a continuous conveyor for muck removal, rolling stock, spare parts, and cutting tools.

The largest global anthracite producer, Sibanthracite Group, is taking on the tunnel construction with management by VostokCoal Management Company. The companies, owned by Dmitry Bosov, aim to increase coal transport by up to 100 million tonnes per year through the addition of the second tunnel. “Robbins has established itself on the market as the best manufacturer of hard rock machines, which are able to provide the maximum penetration rate in hard rock. This is one of the determining factors in connection with the tight deadlines for the implementation of our project. Also, Robbins is the only manufacturer to build the Crossover TBM,” said a representative of Sibanthracite Group. Other aspects of the supply include a continuous conveyor for muck removal, rolling stock, spare parts, and cutting tools.

Sibanthracite Group chose Crossover technology for a number of reasons, geology being chief among them. “A Crossover type tunnel boring machine was selected for tunneling due to the fact that the construction of the tunnel will be carried out in difficult heterogeneous geological conditions (from unstable waterlogged soils to hard rock). The Crossover is able to operate in two modes: Open mode, used while boring in hard rock formations, and closed mode (with earth pressure balance), used when boring in unstable water-logged soils,” said the Sibanthracite representative.

The lessons learned during the first Severomuysky tunnel—the importance of probe drilling, consolidation grouting, and preventing a shielded machine from becoming stuck in fault zones or squeezing ground—are all part of the Crossover TBM solution. “I was a young engineer working at Robbins when the Double Shield TBM was delivered for the first tunnel, so it is a special honor to bring this new technology to the second Severomuysky Tunnel in Siberia,” said Robbins President Lok Home. “Per the contract Robbins is supplying Crossover TBMs for the new parallel rail tunnel—these machines are made to bore in highly variable ground conditions while maintaining good advance rates. With our latest technology we hope to again prove TBMs are the better choice over Drill and Blast when difficult ground conditions are to be encountered.”

The machines will be designed for varying water pressures, ranging from 5 to 20 bar. They will feature Water Inflow Control, a system that seals off the face and periphery and creates a safe working environment in which to dewater and consolidate ground. The machines will feature probe drill ports and capabilities for 360-degree probe drilling and grouting ahead of the excavation face, while the Robbins Torque-Shift System will enable the machines to bore through collapsing ground and other situations that demand high torque. The machines will also be designed with a belt conveyor in hard rock mode that can be switched out with a screw conveyor when crossing into soft ground.

Crews will bore through the Severomuysky Ridge, a mountain range in Buryatia and part of the Stanovoy Highlands, which separates the basins of the Upper Angara and Muya Rivers. “The second Severomuysky tunnel is located in one of the most geologically active areas of our planet—on the north-eastern flank of the Baikal rift zone. The region is characterized by high seismic activity, difficult geological and hydrogeological conditions against the backdrop of a harsh climate (the summer period lasts only 80-100 days, temperatures from + 39°C in summer to -58°C in winter). The construction work on the portals is complicated by the presence of permafrost as well,” said the Sibanthracite representative. Construction of the new tunnel is expected to begin in 2020 and take five years.

Image 1: The original 4.56 m diameter Double Shield machine was supplied for the Severomuysky Service Tunnel in 1979.

Image 2: The new 10.37 m Robbins Crossover (XRE) TBMs are designed for highly variable geology and will have a belt conveyor that can be switched out with a screw conveyor in challenging conditions.

Industry News, trenchless products

November 2019: Barbco, Inc. Co-Owner and CEO, Anthony R. Barbera was granted U.S. Patent #10465460 for the Barbco FlexBor tooling and technology on November 5, 2019! This is a proud moment in this East Canton, Ohio manufacturer’s storied 30-year history of driving the trenchless technology, horizontal boring, and underground manufacturing industries forward with world class capital equipment and cutting-edge technology. The FlexBor is an extremely cost-effective, environmentally safe trenchless method and tooling. The FlexBor is designed to virtually eliminate “frac-outs” / ”inadvertent returns” that are often associated with horizontal directional drilling and the use of bentonite.

November 2019: Barbco, Inc. Co-Owner and CEO, Anthony R. Barbera was granted U.S. Patent #10465460 for the Barbco FlexBor tooling and technology on November 5, 2019! This is a proud moment in this East Canton, Ohio manufacturer’s storied 30-year history of driving the trenchless technology, horizontal boring, and underground manufacturing industries forward with world class capital equipment and cutting-edge technology. The FlexBor is an extremely cost-effective, environmentally safe trenchless method and tooling. The FlexBor is designed to virtually eliminate “frac-outs” / ”inadvertent returns” that are often associated with horizontal directional drilling and the use of bentonite.

The Patent Abstract reads: “A cutting assembly and method for drilling an underground borehole. The cutting assembly includes front and rear cutting heads of different diameters mounted on a shaft. An air passage defined through the cutting assembly may be placed in fluid communication with a pressurized remote air source and with a bore of a casing extending rearwardly from the cutting assembly. Pressurized air flows through the air passage and entrains cuttings produced by the front and rear cutting heads. A housing extends rearwardly from the larger diameter rear cutting head and an auger provided within the housing aids in directing cuttings into the casing. The auger rotates independently of the rest of the cutting assembly and may be configured to further reduce the size of the cuttings. A collar on the housing seals the borehole cut by the rear cutting assembly and aids in preventing frac-out.”

The Patent Abstract reads: “A cutting assembly and method for drilling an underground borehole. The cutting assembly includes front and rear cutting heads of different diameters mounted on a shaft. An air passage defined through the cutting assembly may be placed in fluid communication with a pressurized remote air source and with a bore of a casing extending rearwardly from the cutting assembly. Pressurized air flows through the air passage and entrains cuttings produced by the front and rear cutting heads. A housing extends rearwardly from the larger diameter rear cutting head and an auger provided within the housing aids in directing cuttings into the casing. The auger rotates independently of the rest of the cutting assembly and may be configured to further reduce the size of the cuttings. A collar on the housing seals the borehole cut by the rear cutting assembly and aids in preventing frac-out.”

Visit the Barbco website for more details.

Industry News

Join NASSCO in an industry-wide webinar as the Trenchless Technology Center at Louisiana Tech (TTC) presents their findings on the Cured-in-Place Pipe (CIPP) Emissions Testing Study – Phase II.

In response to published reports on the safety of styrene emissions used in cured-in-place pipe (CIPP), NASSCO, Inc. proactively supported research in its quest to ensure workers and the public are safe.

Phase 1 was a four-month study which focused on the review of published literature pertaining to chemical emissions during CIPP installations using styrene-based resins. The study, completed on April 6, 2018 by researchers at the University of Texas at Arlington (UTA)’s Center for Underground Infrastructure Research and Education (CUIRE), and the Institute for Underground Infrastructure (IKT) in Germany, found that existing studies do not adequately capture worker exposures or levels in the surrounding areas to which workers or citizens may be exposed. The team further determined that spatial variation of concentrations, and variations in concentrations with different meteorological conditions, are not well determined.

Phase 2 of a larger, in-field study conducted by the Trenchless Technology Center (TTC) at Louisiana Tech, recently concluded and findings will be shared via webinar on December 17, 2019. The year-long study included measurement of styrene and other organic compounds at multiple CIPP installation sites across the country, representing different pipe diameters (8”, 12”, and larger), and lengths, in order to capture variation in emissions. Measurements were conducted before, during, and after curing at the termination manhole, as well as various locations in the surrounding outside area and inside nearby buildings. Worker exposure was also measured via personal exposure monitors. Finally, dispersion modeling was conducted to estimate compound concentrations at different locations for a wide variety of meteorological conditions. Measured and modeled concentrations were compared to appropriate health-based action levels to determine if any potential health risks exist for workers or citizens in the surrounding communities.

The webinar is on December 17, 2019 at 2:00 p.m. Eastern and will cover TTC’s findings and recommendations. Registration is open to all. Click here to register for the webinar.

The Trenchless Technology Center (TTC) at Louisiana Tech University is a cooperative research center for academia, government, and industry. The Center’s mission is to advance trenchless technology by serving as an independent source of knowledge, research, and education in the field. Trenchless technology includes a large family of methods used for installing and rehabilitating underground utility systems with minimal surface disruption and destruction resulting from excavation. The TTC utilizes a three-pronged approach to accomplish its mission: research & development, education, and technology transfer.

Click here to register for the webinar.

Industry News, trenchless people, trenchless products

Conyers, GA – November 15, 2019 – USL Group announced today that it has acquired Logiball Inc., a leading manufacturer of trenchless pipe rehabilitation equipment headquartered in Quebec, Canada. Terms of the transaction were not disclosed.

Conyers, GA – November 15, 2019 – USL Group announced today that it has acquired Logiball Inc., a leading manufacturer of trenchless pipe rehabilitation equipment headquartered in Quebec, Canada. Terms of the transaction were not disclosed.

Founded in the early 1980s, Logiball holds a leading position in the manufacturing and supply of inflatable pipe plugs and test-and-seal injection packers for the maintenance and trenchless rehabilitation of collection systems and gravity pipes compromised by groundwater intrusion – a sizable segment of the general infrastructure sector known as the Inflow and Infiltration (I&I) market.

Logiball’s main product range is test-and-seal injection packers, which are used to confine and apply grouts for the repair of points of water ingress and egress from pipes, such as leaking joints or cracks. Logiball is the primary producer of these specialized products, which has allowed the company to forge a strong position in the niche of the I&I market.

“This acquisition provides channel synergies for both Logiball and our Prime Resins business, which makes chemical grouts. It will enable both companies to expand their reach in the growing I&I market space by leveraging their joint reputations and product offerings” said John Taylor, Director at USL Group. “Prime Resins has actively pursued growth in this market space, and the clear synergies with Logiball will lead to product improvement and expansion of use that will benefit the Trenchless Rehabilitation industry as a whole”.

About USL

Founded in 1981, USL Group of companies are market leaders in the provision of specialist civil engineering and construction solutions. For nearly four decades, USL Group has been at the forefront of cutting-edge resin and cementitious technology, combining high performing innovative products, first class operations, expert technical support and unrivalled customer service. Specializing in expansion joints, structural and liquid waterproofing, construction chemicals, concrete repair systems, injection resins and specialist safety & anti-slip products, USL boasts a comprehensive portfolio of products and a highly developed global network. For more information about USL, visit www.uslgroup.com.

Industry News, trenchless people, trenchless products

Recently two of NASTT’s very dedicated volunteers, Dennis Walsh and George Ragula, both of PSE&G, met with our Rutgers Student Chapter to give a presentation.

Recently two of NASTT’s very dedicated volunteers, Dennis Walsh and George Ragula, both of PSE&G, met with our Rutgers Student Chapter to give a presentation.

The presentation covered a project that is the new world record diameter 42” CIPL renewal that included an extremely complicated piping geometry involving seven bends in a u-tube configuration crossing a major parkway with a significant change in vertical elevation.

The project presentation was fascinating and the students were thrilled to have two industry experts on hand to answer questions and provide insight. Future presentations and job site visits are in the works.

Pictured are volunteers and student members:

Left to right, front row: Max Ritner, Sharon Xiao, Riya Maniar and Kendi Bailey.

Left to right, back row: Amil Muminovic, Demetra Tampasis, George Ragula, Ian Walczak, Anthony Genchi, Dennis Walsh and Troy Dittenhofer.

Industry News, trenchless products, trenchless projects

The following is a post from Akkerman. For more details and additional job site photos, visit their website.

Northwest Boring Co. Inc. (NWB) of Woodinville, WA was subcontracted by Shoreline Construction for an emergency replacement of the City of Mill Creek’s failed 30-inch CMP stormwater pipeline that had been causing flooding in the suburban neighborhood, just north of Seattle.

Northwest Boring Co. Inc. (NWB) of Woodinville, WA was subcontracted by Shoreline Construction for an emergency replacement of the City of Mill Creek’s failed 30-inch CMP stormwater pipeline that had been causing flooding in the suburban neighborhood, just north of Seattle.

The need for the stormwater system’s repair became apparent when a sinkhole appeared in December 2017, between the Sweetwater Ranch and Douglas Fir neighborhoods. Temporary repair work was conducted, but another sinkhole developed in the same location just one month later. After inspection, it was determined that a failed coupler and damage to the 36-inch corrugated metal stormwater pipe was the root cause.

Because the City of Mill Creek had declared this an emergency project with a budget less than $300,000, a public bidding process was not required. Shoreline Construction was selected as the contractor, who subcontracted the trenchless work to NWB.

The alignments scheduled for replacement were positioned within a narrow easement between two homes at an 11-foot depth in difficult ground. With minimal real estate, the depth of installation and geological conditions, NWB knew that their guided boring system would be an ideal installation choice for the new stormwater connections.

The alignments scheduled for replacement were positioned within a narrow easement between two homes at an 11-foot depth in difficult ground. With minimal real estate, the depth of installation and geological conditions, NWB knew that their guided boring system would be an ideal installation choice for the new stormwater connections.

NWB employed the use of their Akkerman GBM 4800 Series Jacking Frame with a high-torque casing adapter attachment for auger boring. The combination made it possible to install the pilot tube passes and 10-foot pipe segments with the torque and jacking force of an auger boring machine but within a smaller shaft. The design utilized one launch shaft to initiate the runs from both directions which further reduced disruption to resident’s properties and saved on project costs.

The ground conditions present were glacial till with rock, which is typical for this region. This ground cannot be displaced with a standard pilot tube steering head so NWB arranged to use special tooling for up to 12,000 psi UCS ground. The drill bit of choice, the Rock Drill Adapter with TriHawk® drill bit, lead the pilot tube passes which established the 140 and 110-linear foot alignments at the necessary line and grade for gravity flow. Simultaneously, a soil appropriate lubrication regime was applied to flush the excavated cuttings back to the launch shaft for removal. (continued)

Crews then prepared to direct jack the 110 and 140-linear foot, 36-inch steel casing. In advance of the casing, NWB launched a guide rod swivel with a 36-inch cutter head which matched the 36-inch casing diameter. The swivel portion of the tooling absorbed the auger rotation while the cutter head, equipped with durable carbide gage cutter bit tooling, excavated the difficult ground. This second pass was completed with the guide rod swivel with cutter head for both stormwater sections.

The alignments were then finished with 27-inch Vylon® carrier pipe was positioned inside the casing and connections to the existing infrastructure were made.

From start to finish the entire project was finalized in just under a month, resolving the City’s dilemma in a timely manner with minor intrusiveness to residents.

Industry News

PELLA, Iowa, Oct. 15, 2019 — Vermeer is expanding its pile driver product line with the introduction of two new models. The Vermeer PD5 and PD5R pile drivers combine efficient operation and accuracy into a compact, lightweight machine well suited for working on smaller solar installation projects, congested jobsites and civil fencing and guardrail installation applications.

PELLA, Iowa, Oct. 15, 2019 — Vermeer is expanding its pile driver product line with the introduction of two new models. The Vermeer PD5 and PD5R pile drivers combine efficient operation and accuracy into a compact, lightweight machine well suited for working on smaller solar installation projects, congested jobsites and civil fencing and guardrail installation applications.

With a 15 foot (4.6 m) mast that can remain fully assembled when transporting and aided by a 90° rotating platform, the design of the PD5 and PD5R can help ease the setup and teardown process. With transportation weights of 10,350 pounds (4694.7 kg) for the PD5 and 10,300 pounds (4672 kg) for the PD5R, multiple units can be transported on a single trailer.

The PD5 features machine-integrated controls located on the side of the machine. The PD5R features a full-function wireless remote control that can engage the hammer, accurately align the pile to complete verticality using the auto plumb feature and position the machine. Both machines can use an optional laser receiver or a compatible third-party GPS system to help improve productivity by better aligning the machine to the specified pile install location.

“The solar industry has experienced tremendous growth in the last few years, and the Vermeer PD10 and PD10R pile drivers have been among the most widespread machines used for installing ground mount solar piles,” explains Ed Savage, product manager at Vermeer. “Of course, not every jobsite is the same, so we created the new PD5R and PD5 pile drivers to give contractors smaller and more lightweight options. These units include many of the same features as the PD10 and have similar productivity in a variety of soil conditions.”

Both pile drivers are powered by a Cat 49 horsepower (36.5 kW) Tier 4 Final diesel engine, have a forward travel speed of 2.6 miles per hour (4.18 km/h) so operators can move quickly from pile to pile and feature a mast pull-down that is rigidly attached to the mast chain to deliver powerful force.

Both machines will be available early 2020.

For more information about the Vermeer PD5 and PD5R pile drivers, visit Vermeer.com or contact your local Vermeer dealer.

Industry News, trenchless projects

The following is a post from Akkerman. For more details and additional job site photos, visit their website.

BRH-Garver Construction LP, a Houston based civil construction contractor pipe jacked 885-linear feet of 66-inch ID Permalok® casing filled with 48-inch carrier lines to convey treated water from the Canal Water Treatment Plant (WTP) for El Paso Water in El Paso, TX. The project risks and rewards existed in equal measure for all stakeholders.

BRH-Garver Construction LP, a Houston based civil construction contractor pipe jacked 885-linear feet of 66-inch ID Permalok® casing filled with 48-inch carrier lines to convey treated water from the Canal Water Treatment Plant (WTP) for El Paso Water in El Paso, TX. The project risks and rewards existed in equal measure for all stakeholders.

The Canal WTP, also known as the Robertson Umbenhauer, was constructed 75-years ago and is situated between the Rio Grande River and a 100-year old BNSF rail yard. The new transmission lines culminate to tie in at San Antonio Avenue in downtown El Paso.

The water lines on the Canal Water Treatment Plant Discharge Main Tunnel project traveled under Highway I-85, and 18 BNSF rail yard tracks in soft ground conditions presenting many opportunities for settlement. El Paso’s water table is prone to seasonal variability due to its proximity to the river, and the likelihood of contaminated ground, existing utilities and obstructions in the 100-year old rail yard posed a potential threat to tunneling personnel and loss of production. Since the launch shaft was in an active BNSF rail yard, frequent and diligent communication and coordination with the railroad personnel transpired for safety, and equipment and material staging.

Several factors contributed to project cost savings including the use of a more cost-effective Tunnel Boring Machine (TBM) system over a microtunneling system, a value-engineered design to initiate both bores from one launch shaft inside the rail yard to emerge into one reception shaft, the downsizing of casing diameter from 72 to 66-inch, and the avoidance of deep well dewatering, which also reduced settlement risk.

The contractor’s pipe jacking experience informed the resolution of the project’s more difficult challenges when completing the 570- and 315-linear foot tunnels. When unforeseen cobbles were discovered, the hydraulic doors on the TBM cutter head provided passage for the cobbles with minimal loss of production. When unpredicted boulders were discovered, although (continued)tunneling had to pause to allow chemical grout to be used to stabilize the bore, the hydraulic doors provided essential access for breaking the boulders to a size that allowed for their passage to successfully complete the tunnel. When the crew ran into unanticipated PPCA ground conditions, the crew persevered by using a full-face mask filtration system to resume mining operations.

The project was deemed successful, and the TBM named “Robbie” in honor of the 75th anniversary of the Robertson Umbenhauer WTP, proved to be the right method.

- Breff Cooling of BRH Garver, comments on the equipment selection, “The versatility of the Akkerman TBM with hydraulically-operated doors, gave us some options that a MTBM would not have. A slurry machine may have been the preferred choice under critically located structures in ground that varies from clay, to sand seams, to running gravels. However, the small but real possibility of boulders, or steel fish plates and other obstructing debris sometimes found under rail yards, tipped the balance towards selecting a manned-entry TBM for accessing any obstructions. With the benefit of hindsight, we can say that the TBM turned out to be the better choice in this case because we ended up discovering unforeseen boulders.”

Cooling also credits the railway stating, “We are grateful for the exceptional cooperation from BNSF for accommodating our field operations inside their busy 24-hour around-the-clock rail yard operations.”

The Canal Water Treatment Plant Discharge Main Tunnel project was designed by a partnership between CDM Smith and Parkhill, Smith & Cooper who also provided site supervision and contract administration. Tunneling technical support, oversight and settlement monitoring was performed by Killduff Underground Engineering.

Cooling concludes, “This is the third time BRH-Garver has partnered with an engineering firm for a design-build project, and the first for time for a tunneling project. The partnership accepted transfer of nearly all risk for the client and proved very effective for BRH to apply three decades of tunneling experience towards the optimum tunneling solution for the design changes. Our preference would be for this type of project delivery all of the time.”

Industry News, trenchless people

Recently the NASTT Student Chapter at UMASS Lowell participated in the school’s annual campus club recruiting event. They had a table at the event outlining what the student chapter does and why trenchless matters. These students are passionate about growing interest in the trenchless industry!

Recently the NASTT Student Chapter at UMASS Lowell participated in the school’s annual campus club recruiting event. They had a table at the event outlining what the student chapter does and why trenchless matters. These students are passionate about growing interest in the trenchless industry!

NASTT volunteer instructor and “Trenchless Guru” (yep, that’s his X handle!), Dennis Doherty, is very involved with the students at UMASS Lowell and volunteers his time to mentor these future trenchless champions. Dennis is the National Practice Leader of Trenchless Technologies at Haley & Aldrich. Dennis said, “Get involved with our students. They are our future”. We couldn’t agree more!

January 2020 – Pipe Lining Supply introduced its Quik‐Coating System in 2017. Today we are happy to announce the Quik‐Coating 2020 System. This system has the exact same core functionality as the initial model with a few exterior changes that have been requested from our customers. These items include a

January 2020 – Pipe Lining Supply introduced its Quik‐Coating System in 2017. Today we are happy to announce the Quik‐Coating 2020 System. This system has the exact same core functionality as the initial model with a few exterior changes that have been requested from our customers. These items include a